Dye-sensitized solar cell photoanode active membrane and preparation method thereof

A solar cell, dye sensitization technology, applied in the field of dye-sensitized solar cell photoanode active film and its preparation, can solve the problems of insufficient electron transport channel, low exciton separation efficiency, low interpenetration, etc., to improve Compatibility and adhesion, wide application range, and the effect of improving the absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 : the concrete process that the present invention prepares photoanode active film is:

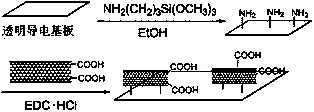

[0029] Modification of transparent conductive substrate: After the transparent conductive solid substrate fluorine-doped tin oxide glass (FTO) is treated with aminosiloxane, the surface is modified with a layer of amino groups, and then soaked in carboxyl carbon nanotubes N,N - In dimethylformamide (DMF) solution, CNTs are automatically bonded under the action of EDC·HCl (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride) To the amino groups on the surface of the solid substrate, a layer of carbon nanotubes can be bonded on the solid substrate (see figure 1 );

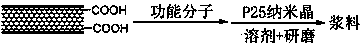

[0030] Preparation of modified carbon nanotubes: Soak double-walled carboxyl carbon nanotubes in tetrabutyl titanate solution (mass ratio: 1:1000), stir and react in a water bath at 45°C for 2 hours, and then filter to obtain modified carbon nanotubes ;

[0031] Preparation of slurry: put modi...

Embodiment 2

[0035] Modification of transparent conductive substrate: After the transparent conductive solid substrate indium tin oxide glass (ITO) is treated with aminosiloxane, the surface is modified with a layer of amino groups, and then soaked in carboxyl carbon nanotubes N,N - In dimethylformamide (DMF) solution, CNTs are automatically bonded under the action of EDC·HCl (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride) To the amino groups on the surface of the solid substrate, a layer of carbon nanotubes can be bonded on the solid substrate (see figure 1 );

[0036] Preparation of modified carbon nanotubes: Soak single-walled carboxyl carbon nanotubes in tetrabutyl silicate solution (mass ratio: 1:1000), stir and react in a water bath at 45°C for 2 hours, and then filter to obtain modified carbon nanotubes ;

[0037] Preparation of slurry: put modified carbon nanotubes and P25 nanocrystals (mass ratio 5:1000) into a mortar, and add cellulose acetate and ethanol ...

Embodiment 3

[0041] Modification of transparent conductive substrate: After the transparent conductive solid substrate indium tin oxide glass (ITO) is treated with aminosiloxane, the surface is modified with a layer of amino groups, and then soaked in carboxyl carbon nanotubes N,N- In dimethylformamide (DMF) solution, CNTs are automatically bonded under the action of EDC·HCl (1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride) To the amino group on the surface of the solid substrate, a layer of carbon nanotubes can be bonded on the solid substrate;

[0042] Preparation of modified carbon nanotubes: Soak single-walled carboxyl carbon nanotubes in a mercaptosiloxane solution (mass ratio: 1:1000), stir and react in a water bath at 45°C for 2 hours, and then filter to obtain modified carbon nanotubes;

[0043] Preparation of slurry: put modified carbon nanotubes and P25 nanocrystals (mass ratio 3:1000) into a mortar, and add cellulose acetate and ethanol for grinding. The mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com