Assembly oil seal with sensing function

An assembly oil and function technology, which is applied to the sealing of engines, devices using optical methods, devices using electrical/magnetic methods, etc., can solve problems such as poor accuracy guarantee, assembly errors, and inaccurate statistics. Accurate detection of crankshaft speed, reduction of circular runout error, unique effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

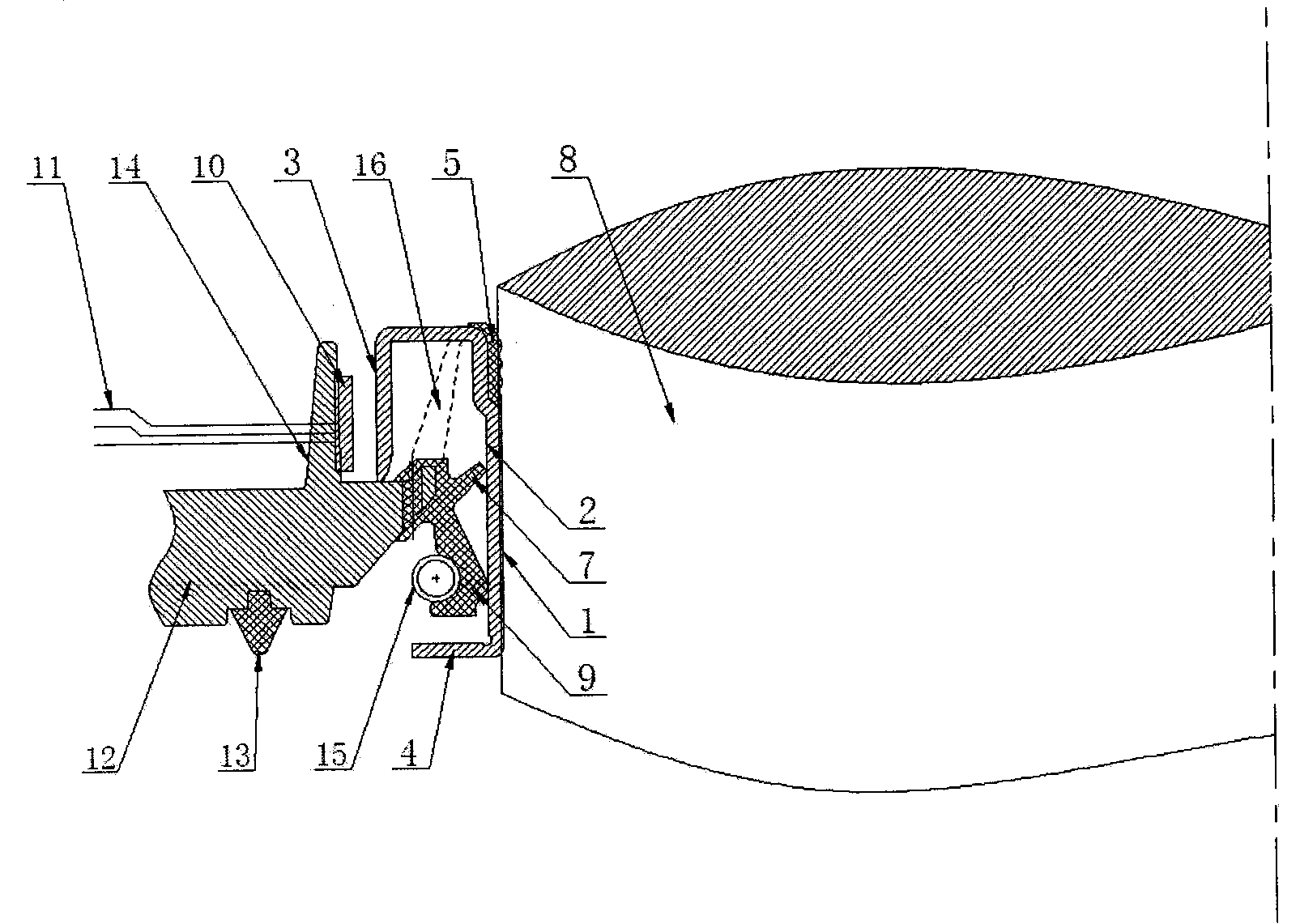

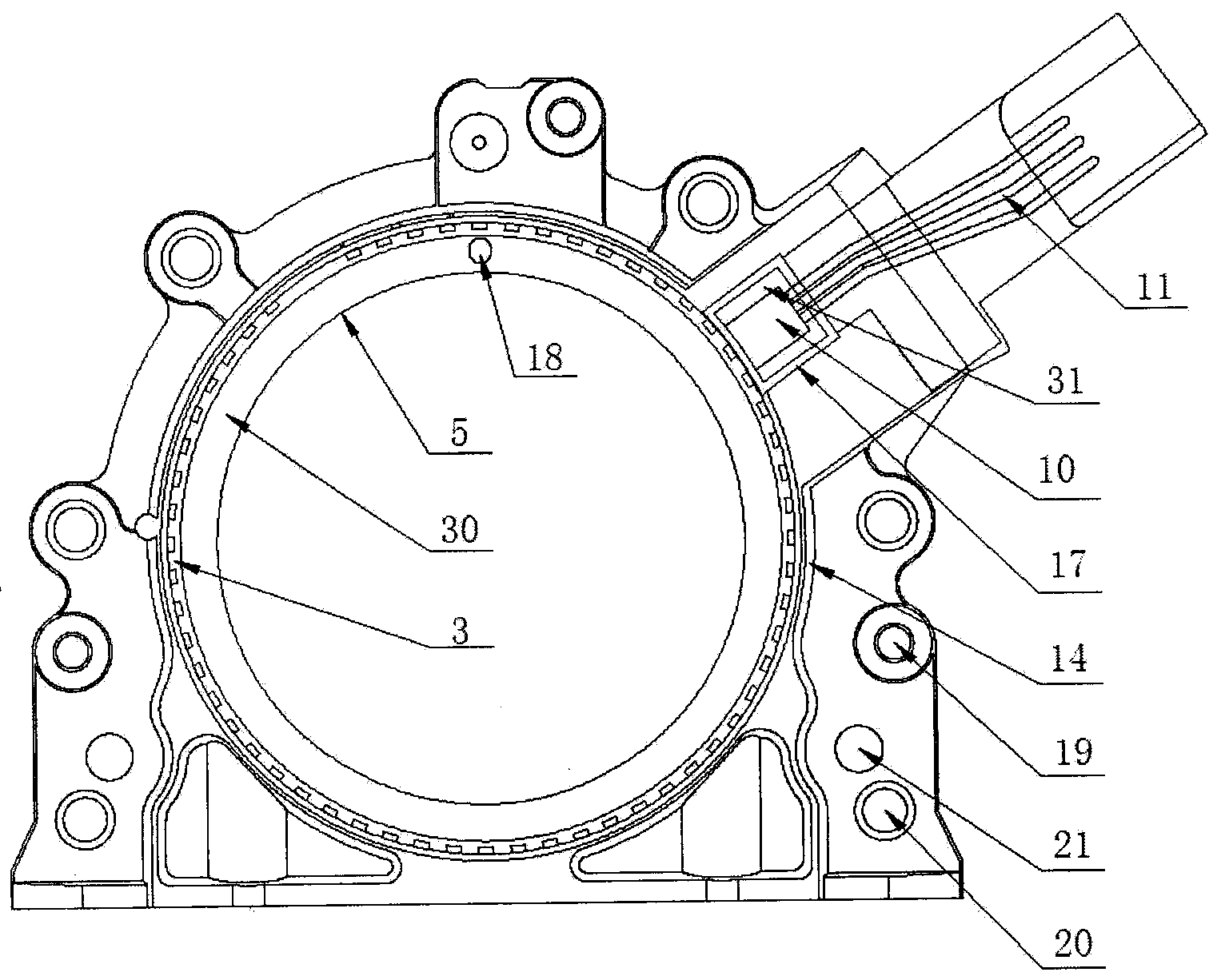

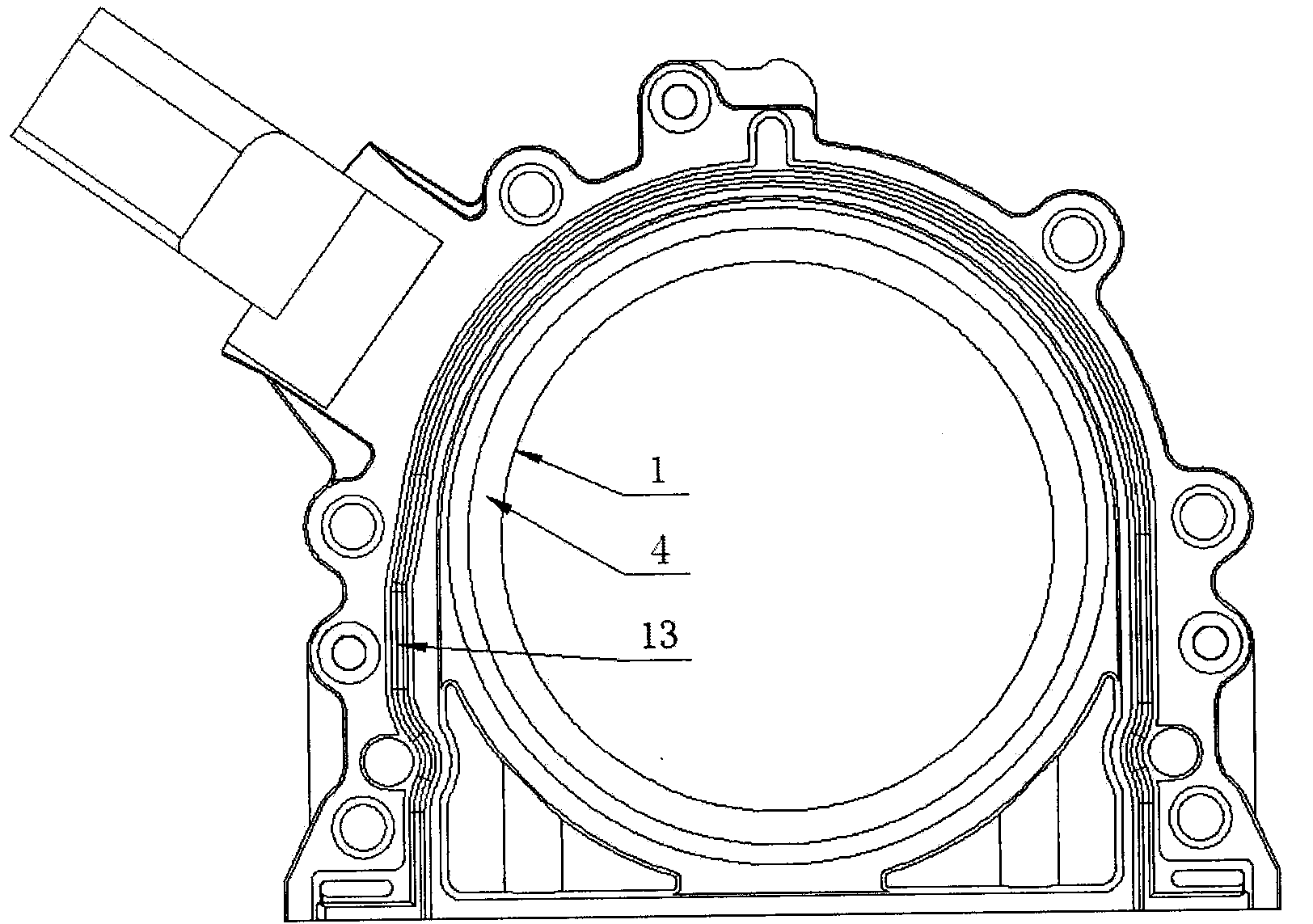

[0062] Such as Figure 1-4 As shown, the oil seal with sensing function of the present invention includes a flange 12, an oil seal lip matched with the inner ring of the flange 12, an encoder, and a sensor corresponding to the encoder.

[0063] The oil seal lip includes a main lip 9 and an auxiliary lip 7 or 16.

[0064] The sensor includes a sensor chip 10, a data transmission line and an output port 11, which play the role of transmitting rotational speed information.

[0065] The encoder is an inverted U-shaped ring with one end long and one end short. The short end of the encoder is the encoder body 3, which is arranged on the flange 12. The inside of the long end of the encoder matches the inner ring of the lip of the oil seal.

[0066] The long end of the encoder is the sealing shaft 2, which is used to contact the main lip 9, auxiliary lip 7, and 16 of the oil seal lip. The main lip 9 and the sealing shaft 2 prevent internal leakage of the sealing medium, and the auxil...

Embodiment 2-4

[0120] Embodiment 2-4 is the different formulations of the rubber magnetic layer material containing HNBR, specifically see the following table:

[0121] name

Example 2

Example 3

Example 4

HNBR

100

100

100

800

1000

850

rubber softening oil

30

25

22

Active agent ZnO

2

4

3

Active agent MgO

6

4

5

0.7

0.75

0.8

[0122] Antiager 445

2

4

3

lubricant paraffin

1.2

0.8

1

Release agent TM-80

1

2

1.5

4

2

3

Vulcanizing agent DCP

6

5

Vulcanizing agent MOCA

4

Cross-linking agent TAC

3

Cross-linking agent TAIC

5

4

[0123] After testing, the rubber magnetic layer material has good resistance to high temperature, o...

Embodiment 5-7

[0136] Embodiments 5-7 are different formulations of ACM-containing rubber magnetic layer materials, as shown in the following table:

[0137]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com