Stainless steel passivating method and used mixed solution

A mixed solution and stainless steel technology, which is applied in the coating process of metal materials, etc., can solve the problems of reduced pollution, atmospheric and pickling environmental pollution, and reduced storage difficulty of sulfuric acid and solid nitrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

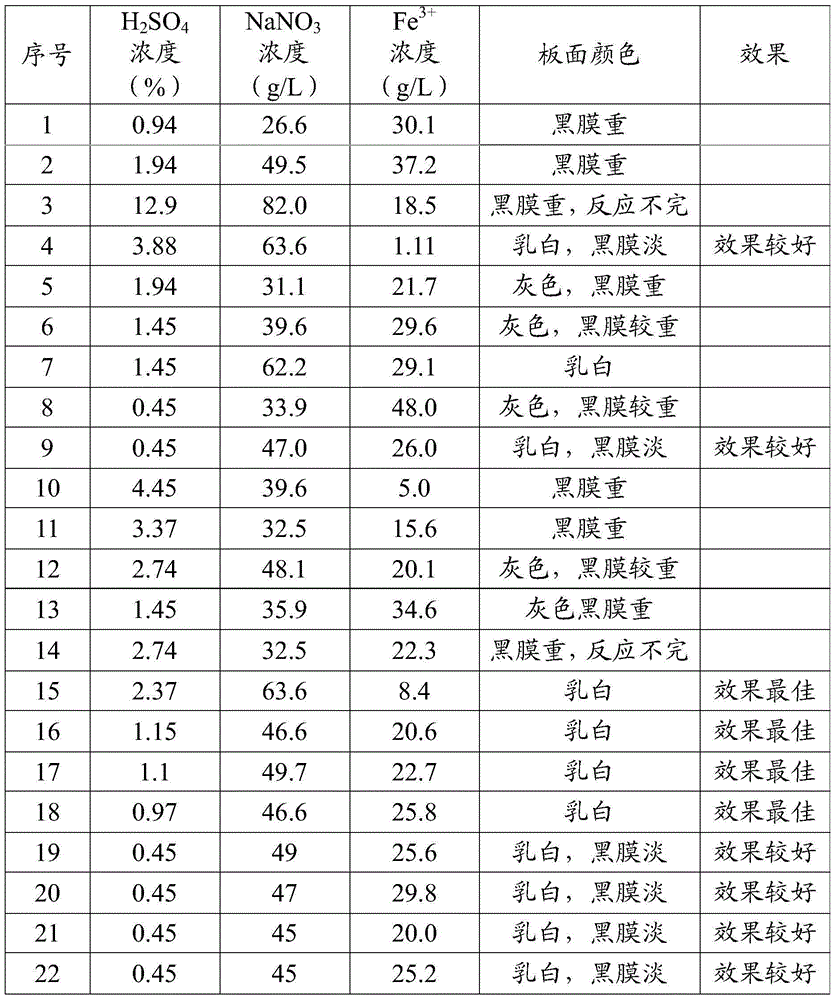

Examples

Embodiment Construction

[0017] A flowchart of a method of passivating stainless steel according to an exemplary embodiment of the present invention will be described with reference to process drawings. In the exemplary embodiment, taking the dipping method as an example, various embodiments in which the mixed solution according to the present invention is used to passivate the stainless steel plate are described to illustrate the characteristics and other advantages of the present invention.

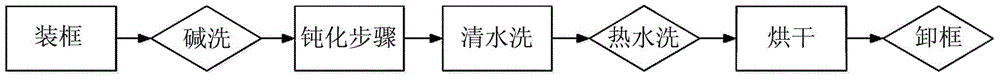

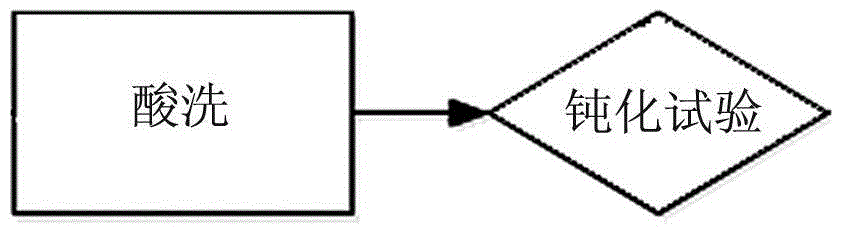

[0018] figure 1 Is a flowchart of a method for passivating stainless steel according to an embodiment of the present invention, figure 2 It is a schematic diagram of a passivation stainless steel process according to an embodiment of the present invention.

[0019] in figure 1 In the process of framing, alkaline washing, passivation, clean water washing, hot water washing, drying and unframing of the stainless steel plate, the treatment of stainless steel is completed. The framing is the step of fixing the stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com