Bottom material for steelmaking furnace and using method thereof

A technology for laying bottom materials and steelmaking furnaces, which is applied in the field of electric arc furnace steelmaking or induction furnace steelmaking, and steelmaking furnace bottom materials, to achieve the effects of shortening the time of slag change, eliminating the hazard of boron mud, and strong absorption of inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

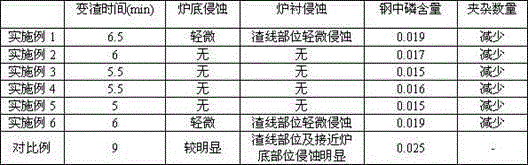

Examples

Embodiment 1

[0021] Ingredients (mass percentage): boron mud 20%, lithium carbonate 4%, potassium carbonate 6%, lime 50%, iron concentrate 15%, aluminum ash 5%.

[0022] For electric arc furnace steelmaking, boron mud, lithium carbonate and potassium carbonate, lime, iron concentrate and aluminum ash are all made into powder and mixed well, then add glucose aqueous solution with a concentration of 5wt%, the amount of glucose aqueous solution added is the mass of the bottom layer 2% of the fraction, and then mix water so that the water content (mass fraction) of the mixture is 8%. After pressing the ball, dry it at 300 degrees Celsius and then pack it in a moisture-proof package. It is used in the electric arc furnace steelmaking furnace, and the addition amount is 1% of the total weight of the metal material in the furnace.

Embodiment 2

[0024] Ingredients (mass percentage): boron mud 10%, lithium carbonate 4%, lime 70%, iron concentrate 15%, aluminum ash 1%.

[0025] For electric arc furnace steelmaking, boron mud, lithium carbonate, lime, iron concentrate and aluminum ash are all made into powder and mixed evenly, then add glucose with a concentration of 6wt%, and the amount of glucose aqueous solution added is 3% of the mass fraction of the primer , and then mix water so that the water content (mass fraction) of the mixture is 7%. After pressing the ball, dry it at 300 degrees Celsius and then pack it in a moisture-proof package. For use in steel furnaces, the amount added is 3% of the total weight of the metal material in the furnace.

Embodiment 3

[0027] Ingredients (mass percentage): boron mud 15%, lithium carbonate 2%, potassium carbonate 4%, sodium carbonate 2%, lime 55%, iron concentrate 17%, aluminum ash 5%.

[0028] It is used for 5 tons of electric arc furnace steelmaking as a base material. Boron mud, lithium carbonate and potassium carbonate, lime, iron concentrate and aluminum ash are all made into powder and mixed with 5wt% glucose. The addition of glucose solution is 2% of the mass fraction of the bottoming material, and then add water so that the water content (mass fraction) of the mixture is 7%, dry it at 300 degrees Celsius and then pack it in a moisture-proof package. 5% of the total weight of the metal charge into the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com