Asphalt resin-based cold regenerant and regenerated mixture

A technology of asphalt resin and cold regenerant, which is used in building thermal insulation materials, building components, buildings, etc., can solve the problems of poor pavement, low strength, and limited amount of used materials, and achieves low temperature sensitivity, high pavement strength, and construction. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

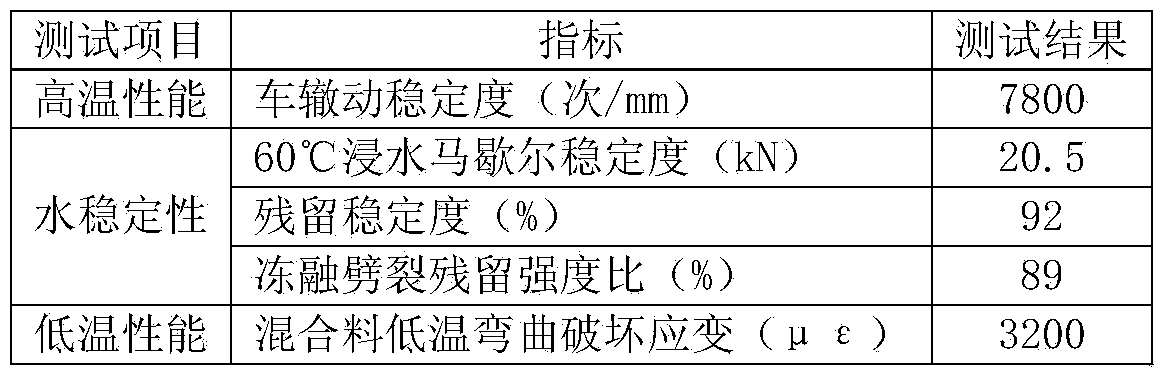

Embodiment 1

[0042] The asphalt resin-based cold rejuvenator of this embodiment comprises by weight: resin emulsion 60, cement 10, phase solvent 25, aggregate surface hydrophobic agent 0.15, curing agent 5, coupling agent 0.1 and antiaging agent 0.25;

[0043] In this embodiment, the resin emulsion is an epoxy resin emulsion; the curing agent is 2, 4, 6 tris(dimethylaminomethyl)phenol, and phenalkamine, aldimine, ketimine, triethanolamine can be used , T31 curing agent or 593 curing agent, or a mixture of several types. The results of the test have proved that there is no obvious difference in the effect of the obtained product; the cement uses high-alumina cement, which can be sulfoaluminate cement or Portland cement, or it can be Several kinds of mixtures have been proved by tests that there is no significant difference in the effect of the obtained products; the phase solvent adopts aromatic oil, and can use naphthenic oil, dimethyl succinate, dimethyl glutarate, dimethyl adipate, Hydro...

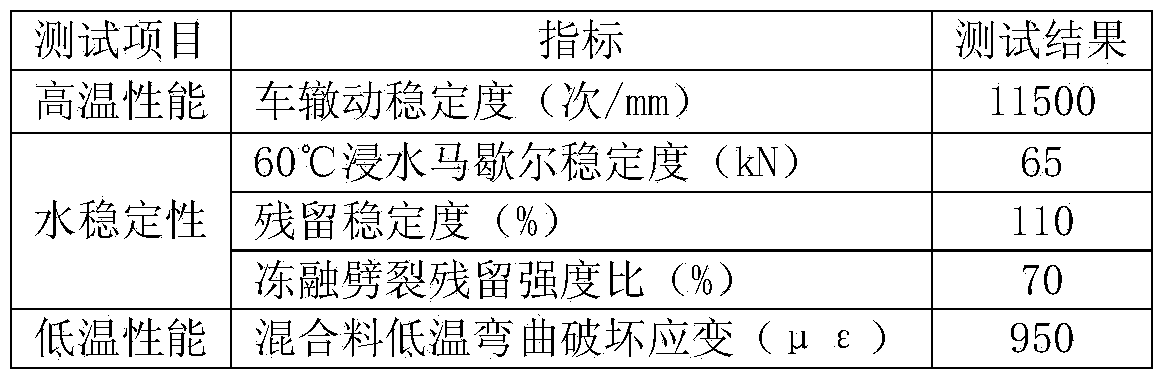

Embodiment 2

[0050] The asphalt resin-based cold regeneration agent of the present embodiment comprises by weight: resin emulsion 10, cement 25, phase solvent 5, aggregate surface hydrophobic agent 0.02, curing agent 0.5, coupling agent 1 and antiaging agent 0.05;

[0051] In this embodiment, the resin emulsion is an epoxy resin emulsion; the curing agent is phenalkamine, which can be 2, 4, 6 tris (dimethylaminomethyl) phenol, aldimine, ketimine, triethanolamine , T31 curing agent or 593 curing agent, or a mixture of several types. The results of the test have proved that there is no obvious difference in the effect of the obtained product; the cement is made of sulfoaluminate cement, and high alumina cement or Portland cement can be used, or it can be Several kinds of mixtures have been proved by experiments that there is no significant difference in the effect of the products obtained; the phase solvent is naphthenic oil, and aromatic oil, dimethyl succinate, dimethyl glutarate, dimethyl ...

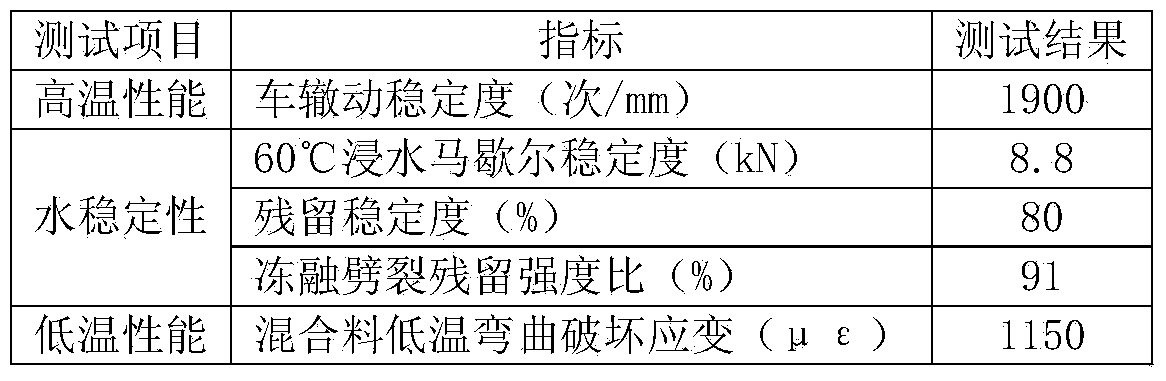

Embodiment 3

[0057] The asphalt resin-based cold rejuvenator of this embodiment comprises by weight: resin emulsion 100, cement 5, phase solvent 50, aggregate surface hydrophobic agent 5, curing agent 45, coupling agent 0.02 and antiaging agent 1;

[0058]In this embodiment, the resin emulsion is an epoxy resin emulsion; the curing agent is phenalkamine, which can be 2, 4, 6 tris (dimethylaminomethyl) phenol, aldimine, ketimine, triethanolamine , T31 curing agent or 593 curing agent, or a mixture of several types. The results of the test have proved that there is no obvious difference in the effect of the obtained product; Portland cement is used for cement, and high alumina cement or sulfoaluminate cement can be used, or it can be Several kinds of mixtures have been proved by experiments that the effect of the obtained products has no obvious difference; the phase solvent is hydrogenated castor oil, naphthenic oil, dimethyl succinate, dimethyl glutarate, dimethyl adipate can be used , aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com