Preparation method for nitride phosphor/glass composite luminescent sheet layer

A technology of nitride phosphors and light-emitting sheets, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of damage to the properties of phosphors, aging of resin and silica gel, affecting image quality, etc., and achieves low equipment requirements. , good thermal stability, good luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of bismuth salt system glass

[0028] The composition of the bismuthate system glass includes Bi 2 o 3 , B 2 o 3 , ZnO and Al 2 o 3 , the mass percentage of each component is Bi 2 o 3 :60%, B 2 o 3 :30%, ZnO:6%, Al 2 o 3 : 4%; weigh Bi according to the formula 2 o 3 、H 3 BO 3 , ZnO and Al 2 o 3 Analysis of pure raw materials, where B 2 o 3 by H 3 BO 3 Introduction; fully grind the weighed raw materials in a mortar, mix them evenly, pour them into an alumina crucible, melt them at 1200°C for 0.5h, quench the molten glass directly in water, and dry, grind and sieve the granular glass to obtain Required low melting point glass powder.

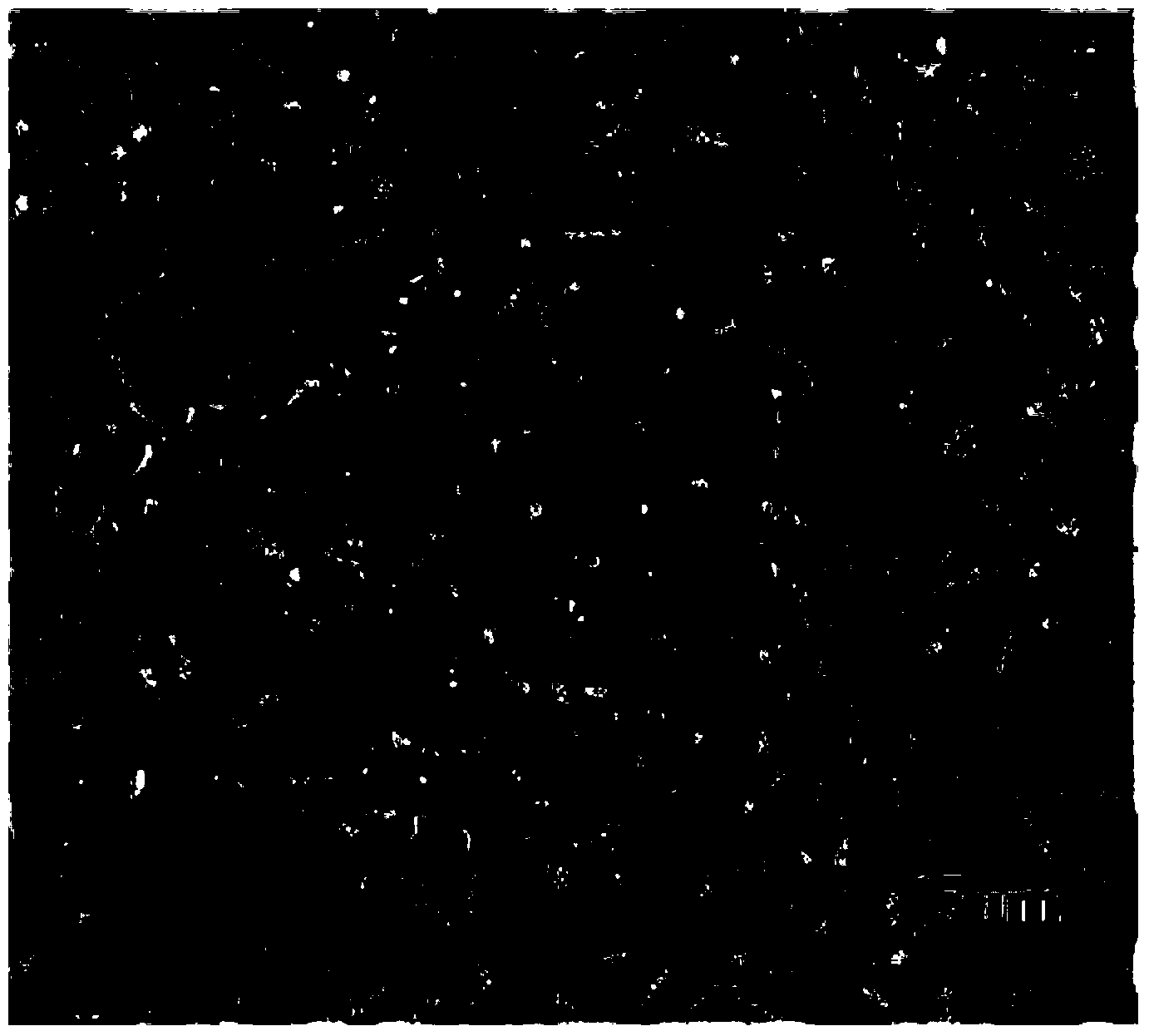

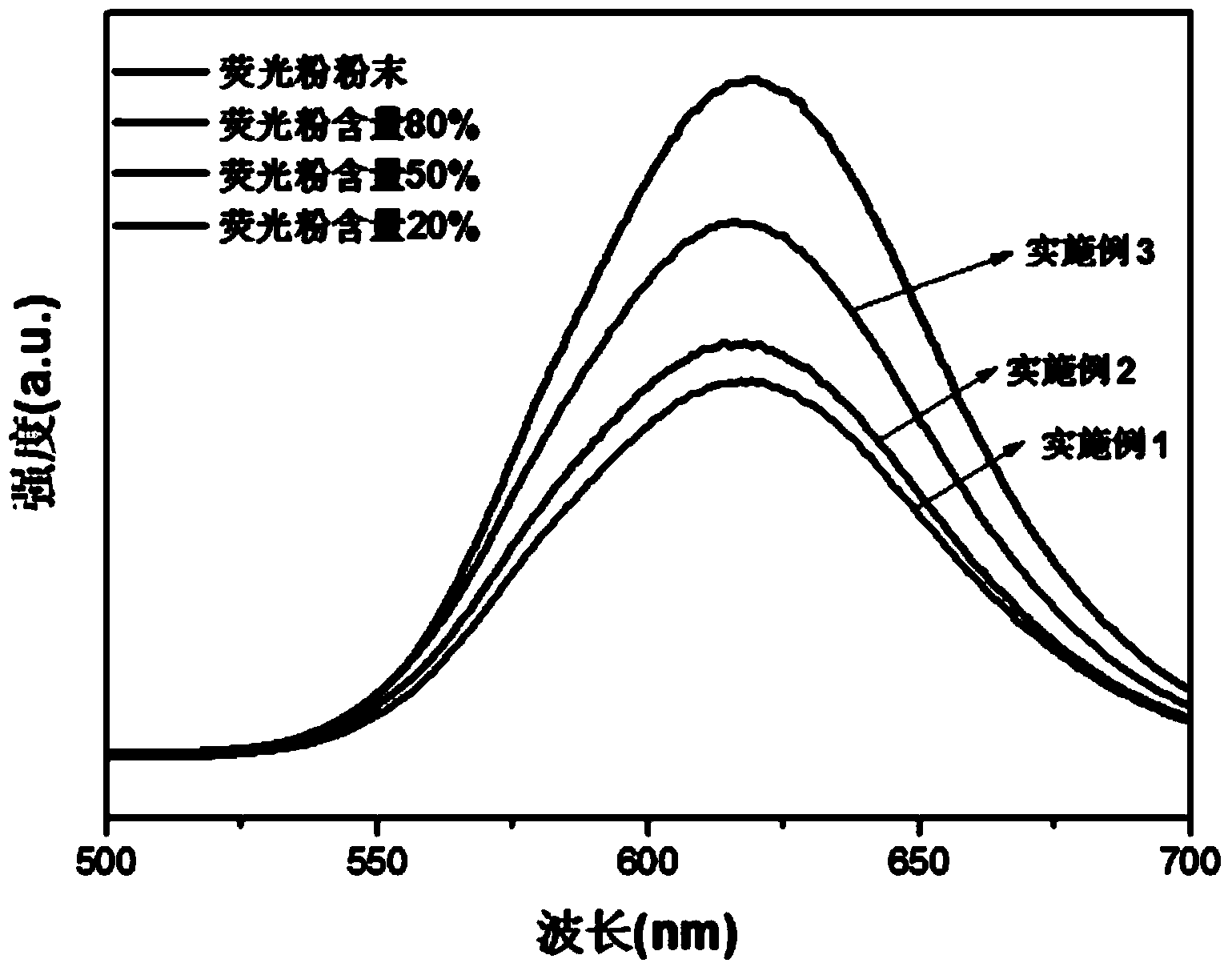

[0029] (2) Preparation of nitride phosphor / glass composite luminescent sheet

[0030] CaAlSiN 3 :Eu 2+ Mix the phosphor powder and the glass powder of the bismuth salt system evenly at a mass ratio of 1:4, spread the mixture into a self-made mold, and flatten it with a tablet press with a pressure of ...

Embodiment 2

[0036] (1) Preparation of bismuth salt system glass

[0037] The composition of the bismuthate system glass includes Bi 2 o 3 , B 2 o 3 , ZnO and Al 2 o 3 , the mass percentage of each component is Bi 2 o 3 :65%, B 2 o 3 :25%, ZnO:7%, Al 2 o 3 : 3%; weigh Bi according to the formula 2 o 3 、H 3 BO 3 , ZnO and Al 2 o 3 Analysis of pure raw materials, where B 2 o 3 by H 3 BO 3 Introduction; fully grind the weighed raw materials in a mortar, mix them evenly, pour them into an alumina crucible, melt them at 1300°C for 1.0h, quench the molten glass directly in water, and dry, grind and sieve the granular glass to obtain Required low melting point glass powder.

[0038] (2) Preparation of nitride phosphor / glass composite luminescent sheet

[0039] CaAlSiN 3 :Eu 2+The phosphor powder and the glass powder of the bismuth salt system were mixed evenly at a mass ratio of 1:1, and the mixture was spread into a self-made mold, and flattened with a tablet press, using...

Embodiment 3

[0043] (1) Preparation of bismuth salt system glass

[0044] The composition of the bismuthate system glass includes Bi 2 o 3 , B 2 o 3 , ZnO and Al 2 o 3 , the mass percentage of each component is Bi 2 o 3 :70%, B 2 o 3 :20%, ZnO:8%, Al 2 o 3 : 2%; weigh Bi according to the formula 2 o 3 、H 3 BO 3 , ZnO and Al 2 o 3 Analysis of pure raw materials, where B 2 o 3 by H 3 BO 3 Introduction; fully grind the weighed raw materials in a mortar, mix them evenly, pour them into an alumina crucible, melt them at 1400°C for 1.5 hours, quench the molten glass liquid directly, and dry, grind and sieve the granular glass to obtain Required low melting point glass powder.

[0045] (2) Preparation of nitride phosphor / glass composite luminescent sheet

[0046] CaAlSiN 3 :Eu 2+ The phosphor powder and the glass powder of the bismuth salt system were mixed evenly at a mass ratio of 4:1, and the mixture was spread into a self-made mold, and flattened with a tablet press, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com