Colored glass ceramic with high lanthanum oxide content

A technology of glass-ceramics and lanthanum oxide, which is applied in the field of colored glass-ceramics with high lanthanum oxide content and its preparation, and can solve problems such as increasing the difficulty of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

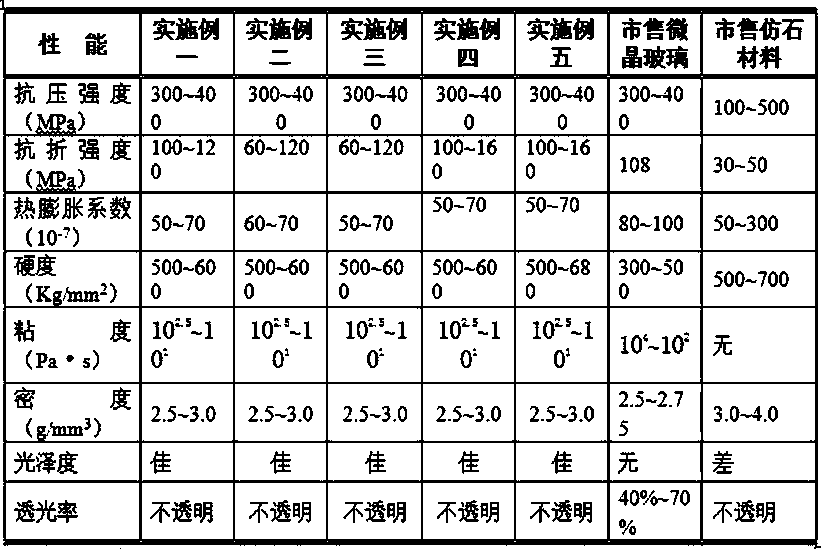

Examples

preparation example Construction

[0026] A preparation method of colored glass-ceramics, the raw materials are configured according to the requirements, the raw materials are passed into the melting part, mixed and then melted to form a molten glass liquid, and then the glass liquid is passed into the cooling part, homogenized, clarified, and air bubbles are discharged in the cooling part , and then discharge the molten glass to the forming part, anneal after forming, and finally make colored glass-ceramic, wherein the temperature in the forming part is kept at 1320 ° C to 1400 ° C, and the time for the glass liquid to be stored in the forming part is 1 to 10 hours. After cooling down, it is annealed after forming, and finally made into colored glass-ceramics. The heat preservation process of the forming part is conducive to the growth of crystal nuclei. Since the raw material may stick in the mold cavity during the crystallization process, the mold cavity needs to be destroyed, so the mold cavity can be made...

Embodiment 1

[0029] A colored glass-ceramic consisting of the following components: 33.3Kg of silicon oxide, 9Kg of calcium oxide, 10.8Kg of magnesium oxide, 13Kg of aluminum oxide, 5.5Kg of lithium oxide, 3Kg of aluminum phosphate, 5.5Kg of calcium fluoride, 2.7Kg of barium oxide, Boron oxide 4.4Kg, potassium oxide 0.2Kg, sodium oxide 0.8Kg, neodymium trioxide 1.5Kg, gold trichloride 0.015Kg, tin dioxide 0.15Kg, manganese dioxide 0.8Kg, zirconia 0.5Kg, bismuth oxide 0.25Kg , titanium oxide 0.25Kg, antimony oxide 1.2Kg, lanthanum oxide 2Kg, cerium carbonate 1.1Kg, zinc oxide 0.02Kg, iron oxide 0.005Kg.

[0030] Raw materials are configured according to requirements, and the raw materials are passed into the melting part, mixed and then melted to form molten glass, and the melting temperature is 1700°C. Then the molten glass is passed into the cooling section, homogenized in the cooling section, clarified, and air bubbles are discharged, and then the molten glass is discharged to the formin...

Embodiment 2

[0032] A colored glass-ceramic consisting of the following components: silicon oxide 33Kg, calcium oxide 9Kg, magnesium oxide 10Kg, aluminum oxide 12Kg, lithium oxide 5Kg, aluminum phosphate 4Kg, calcium fluoride 6Kg, barium oxide 3Kg, boron oxide 5Kg, oxide Potassium 2Kg, sodium oxide 0.1Kg, neodymium trioxide 1.3Kg, gold trichloride 0.01Kg, tin dioxide 0.1Kg, manganese dioxide 0.1Kg, zirconia 0.3Kg, bismuth oxide 0.1Kg, titanium oxide 0.1Kg, oxide Antimony 1.5Kg, lanthanum oxide 2.2Kg, cerium carbonate 1.5Kg, zinc oxide 0.04Kg, iron oxide 0.01Kg.

[0033] Raw materials are configured according to requirements, and the raw materials are passed into the melting part, mixed and then melted to form molten glass, and the melting temperature is 1600°C. Then the molten glass is passed into the cooling section, where it is homogenized, clarified, and air bubbles are discharged, and then the molten glass is discharged to the molding section, and then annealed after molding, and final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com