Preparation method of inorganic compound sodium selenide and device of preparation method

A technology of inorganic compounds and sodium selenide, applied in the direction of binary selenium/tellurium compounds, etc., to ensure the purity, ensure the safety of the reaction, and prevent the pressure from being too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

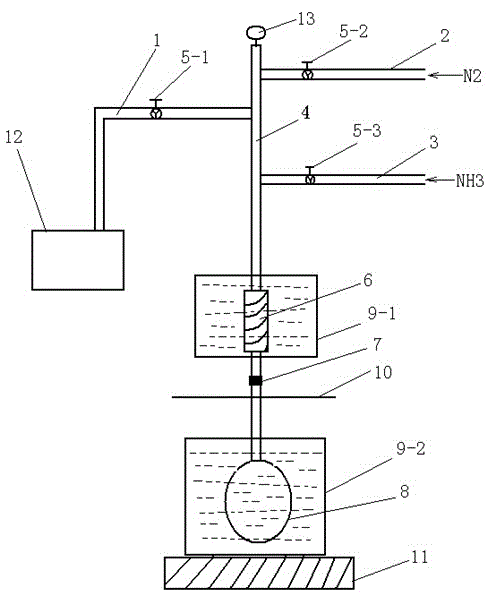

[0049] Such as figure 1 Shown, a kind of device that is used to prepare inorganic compound sodium selenide comprises spherical reactor 8, and the top of described reactor 8 is connected with main pipeline 4 by flange set 7; The top of described main pipeline 4 is respectively connected with The vacuum pump 12 is connected to the vacuum pipeline 1 for vacuuming and the nitrogen pipeline 2 and the ammonia pipeline 3 for feeding nitrogen and ammonia. The bottom of the main pipeline 4 is provided with a gyrotron 6; The bottoms are respectively located in the first cooling pool 9-1 and the second cooling pool 9-2 filled with cooling liquid; the bottom of the second cooling pool 9-2 is set on the magnetic stirrer 11. The main pipeline 4 is connected with a barometer 13, and the vacuum pipeline 1, the nitrogen pipeline 2 and the ammonia pipeline 3 are respectively provided with a first three-way piston 5-1, a second three-way piston 5-2, and a third three-way piston. Pistons 5-3. ...

Embodiment 2

[0054] The preparation method of inorganic compound sodium selenide comprises the following steps:

[0055] (1) In a vacuum glove box filled with high-purity argon protection, metal sodium and elemental selenium are put into the reactor with a molar ratio of 2:1, and polytetrafluoroethylene magnets are added at the same time, and then the reaction The device is sealed and removed from the vacuum glove box;

[0056] (2) Evacuate the reactor to a high vacuum, then fill it with high-purity nitrogen, and then evacuate to a high vacuum, repeat high vacuum, nitrogen cleaning, and high vacuum three times;

[0057] (3) Immerse the reactor in a cooling pool equipped with dry ice acetone solution, and then feed liquid ammonia into the reactor to completely dissolve the sodium metal in the liquid ammonia;

[0058] (4) Pass high-purity nitrogen into the reactor to discharge the gasified ammonia in the reactor;

[0059] (5) Use a magnetic stirrer to stir the mixed solution in the reactor...

Embodiment 3

[0065] The preparation method of inorganic compound sodium selenide comprises the following steps:

[0066] (1) In a vacuum glove box filled with high-purity argon protection, metal sodium and elemental selenium are put into the reactor with a molar ratio of 2:1, and polytetrafluoroethylene magnets are added at the same time, and then the reaction The device is sealed and removed from the vacuum glove box;

[0067] (2) Evacuate the reactor to a high vacuum, then fill it with high-purity nitrogen, and then evacuate it to a high vacuum, repeat high vacuum pumping, nitrogen cleaning, and high vacuum pumping 4 times;

[0068] (3) Immerse the reactor in a cooling pool filled with liquid nitrogen and ethanol mixed solution, and then feed liquid ammonia into the reactor to completely dissolve the metal sodium in the liquid ammonia;

[0069] (4) Pass high-purity nitrogen into the reactor to discharge the gasified ammonia in the reactor;

[0070] (5) Use a magnetic stirrer to stir th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com