resin composition

A technology of resin composition and compound, which is applied in the direction of circuits, electric solid devices, semiconductor devices, etc., can solve the problem that the copper corrosion of the electrode part cannot be prevented, and achieve the effect of excellent preservation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

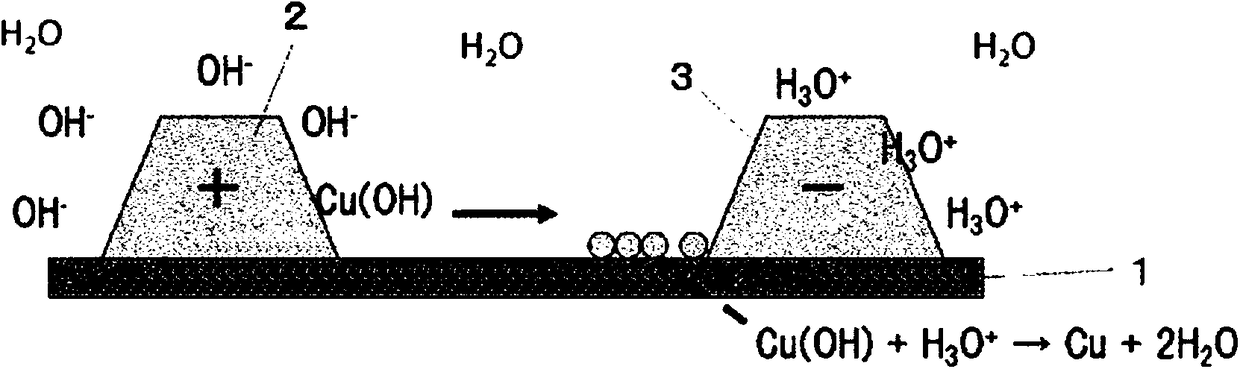

Problems solved by technology

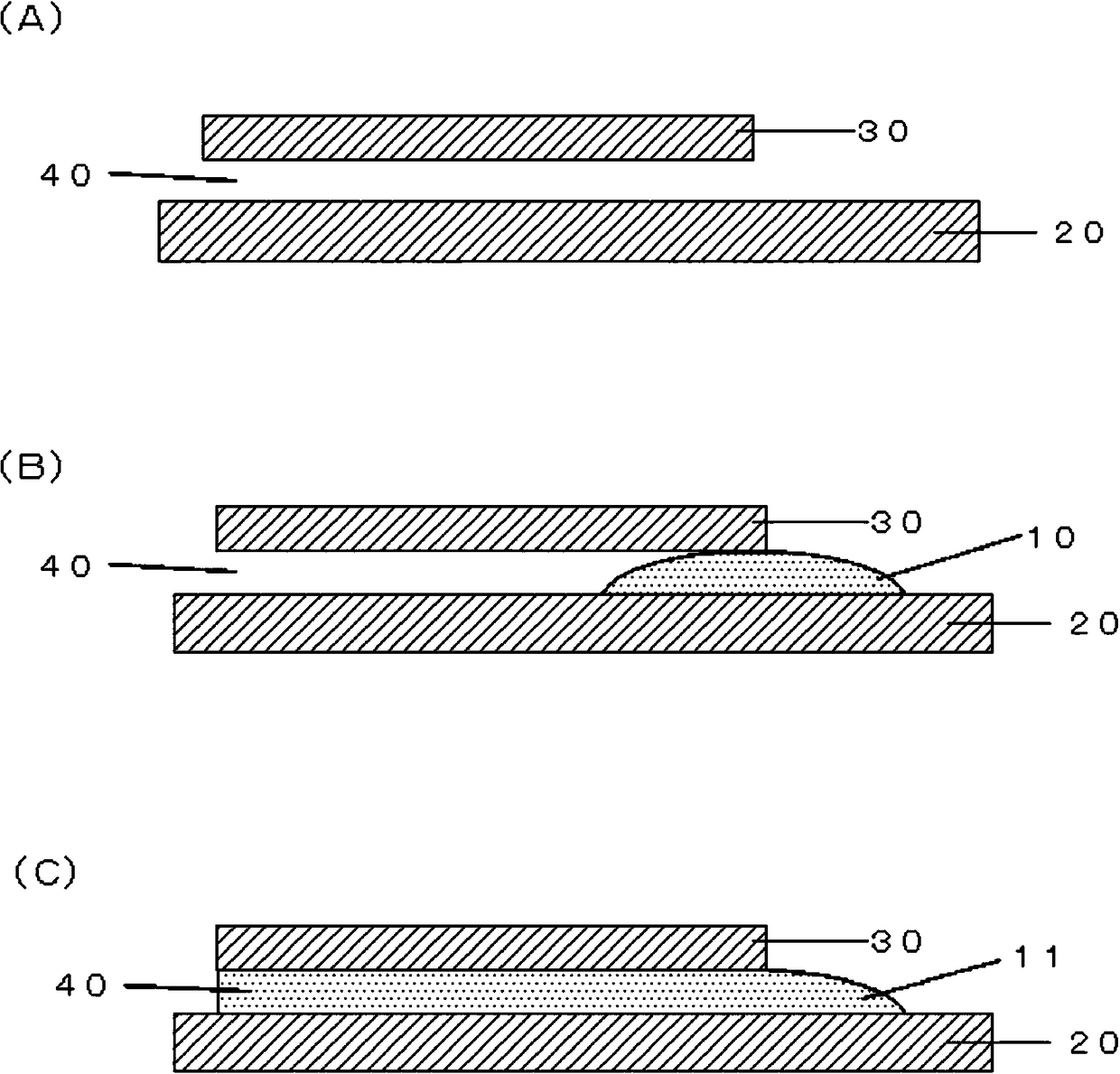

Method used

Image

Examples

Embodiment 1~20、 comparative example 1、2

[0079] The resin composition was prepared according to the proportion shown in Table 1 and Table 2. All the prepared resin compositions are in liquid state. (C) As a component, α-tocopherol, β-tocopherol or α-tocotrienol manufactured by Wako Pure Chemical Industries, Ltd. was used. In addition, in Examples 1-20 and Comparative Examples 1 and 2, the acid anhydride equivalent, amine equivalent or phenol equivalent of (B) component were all 0.8 with respect to 1 epoxy resin equivalent of (A) component.

[0080] [Viscosity evaluation]

[0081] The viscosity (initial viscosity, unit: mPa·s) of the resin composition just produced was measured with the Toki Sangyo Co., Ltd. E-type viscometer (model: TVE-22H). Table 3 and Table 4 show the measurement results of the initial viscosity (denoted as viscosity in the table). In addition, the viscosity of the resin composition after storage at 25°C and 50% relative humidity for 24 hours or 48 hours was measured, and (viscosity after 24 or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com