Type-I collagen material, meninx and meninge biological membrane and preparation method and application of thereof

A collagen material and biofilm technology, used in the preparation of meninges or meninges, the preparation of dura or meninges tissue repair materials, the meninges or meninges biofilms and their preparation, the field of type I collagen materials, can solve the problem Weak mechanical properties, poor suture performance, neurosurgery limitations, etc., to achieve the effect of prolonging the degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

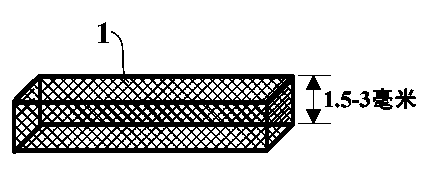

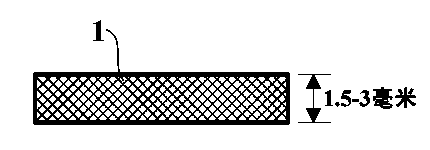

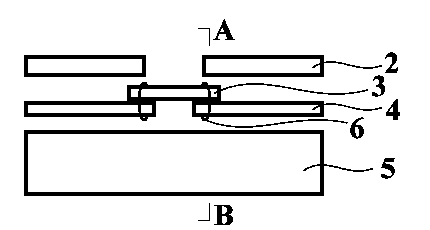

[0075] Embodiment 1: Preparation of 1.0% meninges / spinal membrane biofilm

[0076] 7.2 grams of high-purity type I medical collagen material with a triple helix structure was used to stir in hydrochloric acid at 10,000 and 18,000 speeds for 30 minutes and 1.5 hours to prepare a 1.% concentration collagen composite suspension. Then use sodium hydroxide to adjust its pH to make it reach the state where the viscosity meets the requirements. Take 500 ml and pour it into a 50X50 cm freezing tray, freeze it for 3 to 4 hours at a low temperature of -60 degrees Celsius, and dry it for 15 hours to make a meningeal / spinal membrane biofilm with a pore size of 60 microns and a thickness of 3 mm.

Embodiment 2

[0077] Embodiment 2: Preparation of 2% meninges / spinal membrane biofilm sheet

[0078] 14.4 g of high-purity type I medical collagen material with a triple helix structure was used to stir at 3,000, 10,000, and 18,000 speeds in hydrochloric acid for 30 minutes, 30 minutes, and 1.0 hour to prepare a collagen composite suspension with a concentration of 2%. Then use sodium hydroxide to adjust its pH to make it reach the state where the viscosity meets the requirements. Thereafter, 100% alcohol was added and stirring was continued for 30 minutes. Take 500 ml and pour it into a 50X50 cm freezing tray, freeze it for 3 to 4 hours at a low temperature of -70 degrees Celsius, and dry it for 20 hours to make a meningeal / spinal membrane biofilm with a pore size of 20 microns and a thickness of 2.5 mm.

Embodiment 3

[0079] Embodiment 3: prepare 2.5% meninges / spinal membrane biofilm sheet

[0080] 18 grams of high-purity type I medical collagen material with a triple helix structure was used to stir at 3,000, 10,00, 18,000 and 28,000 speeds for 15 minutes, 30 minutes, 30 minutes and 1 hour under hydrochloric acid environment to prepare 2.5% concentration Collagen complex suspension. Then use sodium hydroxide to adjust its pH and 100% alcohol to make it reach the state where the viscosity meets the requirements. Stirring was continued for 15 minutes. Take 500 ml and pour it into a 50X50 cm freezing tray, freeze it for 3 to 6 hours at a low temperature of -75 degrees Celsius, and dry it for 25 hours to make a meningeal / spinal membrane biofilm with pores less than 20 microns and 2 mm thick.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com