Uniform-speed cooling medium and application thereof in cooling control process after forging

A technology of cooling medium and controlled cooling, which is applied in the field of post-forging cooling of steel forgings, forging and heat treatment of steel forgings, and can solve the problems of difficult promotion of dry cutting technology, anisotropy of mechanical properties, poor low-temperature impact performance, etc. Tissue uniformity, ensuring hardness uniformity, and reducing burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

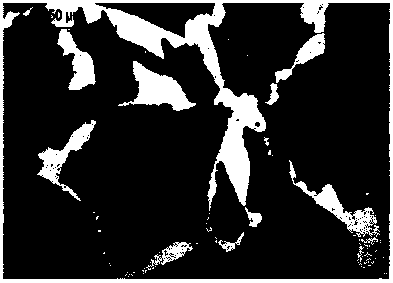

[0051] Example 1: 20CrMnTi rear axle passive tooth blanks, outer diameter 480mm, effective thickness about 50mm, 10 pieces were selected for controlled cooling after forging, directly put into 25% uniform cooling medium after forging for immersion cooling, and compared with the traditional air cooling method. The final forging temperature is about 980°C, and the infrared instrument is used to judge the outlet temperature. The outlet temperature is controlled at 500-600°C, and then transferred to a 640°C soaking furnace for 2 hours of soaking time, and finally air-cooled to room temperature. The stock solution of uniform cooling medium is prepared according to the following formula: polyvinylpyrrolidone accounts for 8%, sodium carboxymethylcellulose (CMC) accounts for 5%, triethanolamine 3% (rust inhibitor), high carbon alcohol defoamer 1 %, 1% isothiazolinone (fungicide), and the rest is water, of which polyvinylpyrrolidone has a molecular weight of 150,000-200,000. The unifor...

example 2

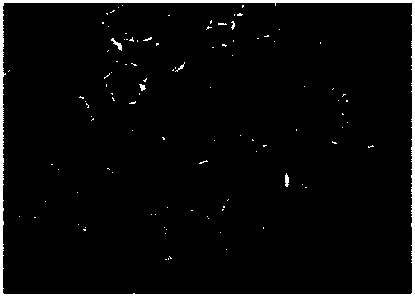

[0055] Example 2: 45# steel front axle (see Figure 7 ), the effective thickness of the fist part is about 100mm, and the effective thickness of the I-beam part is 20-30mm. The traditional method is to cool by air cooling or air cooling after forging, and then perform quenching and tempering treatment (quenching and high temperature tempering). After quenching and tempering treatment, subcutaneous 10mm tissue requires grade 1-4 (testing standard GB / T13320), but traditional methods have always had genetic tissue problems such as Widmanstattenite and reticulated ferrite, and the subsequent heat treatment process cannot be adjusted from Fundamentally solve the problem of unqualified organizations, generally controlled at 4-5 levels.

[0056] After the front axle is forged, it is immersed in 20% uniform cooling medium, and the infrared meter is used to judge the liquid temperature. The temperature of the liquid is controlled at 100-200 ° C, and then air-cooled to room temperature....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com