A zero-discharge treatment system and method for high cod industrial wastewater

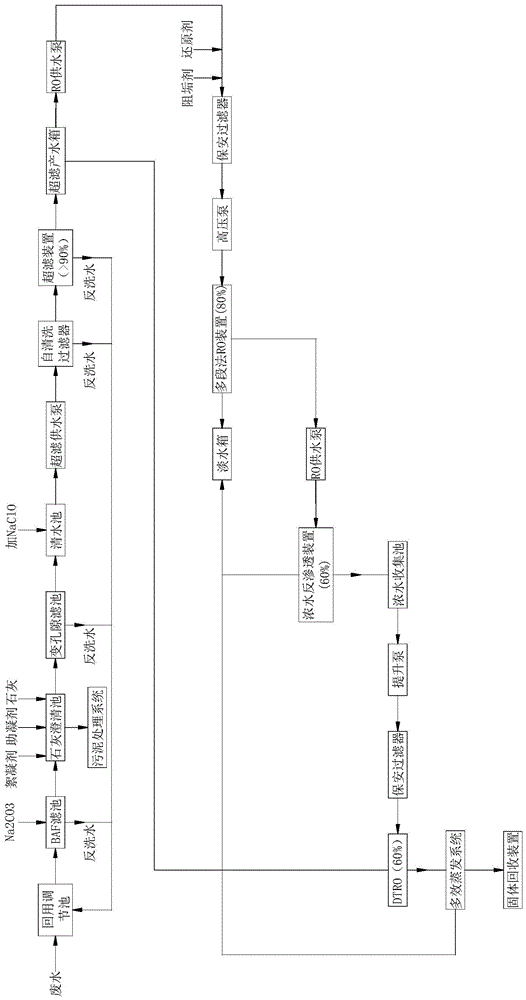

A technology for industrial wastewater and treatment systems, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, general water supply conservation, etc. It can solve the problem of shortening the service life of membrane elements, consuming dissolved oxygen, and destroying water ecosystems problems, to achieve the effect of reducing the process load, strong impact resistance, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the invention:

[0046] 1. Design scale

[0047] 1. The designed influent scale is 550m 3 / h.

[0048] 2. Design water quality:

[0049] The industrial wastewater to be treated includes the standard wastewater of the sewage treatment station, the sewage of the circulating water station, the sewage of the desalinated water station and the unforeseen drainage.

[0050] The comprehensive wastewater quality is expected to be as follows:

[0051] pH7~9;

[0052] Turbidity ~ 40;

[0053] Ca 2+ 190mg / L;

[0054] Mg 2+ 54mg / L;

[0055] Na + +K + 240mg / L;

[0056] Fe 3+ 0.5mg / L;

[0057] HCO 3 - 430mg / L;

[0058] Cl - 370mg / L;

[0059] SO 4 2- 440mg / L;

[0060] CODcr150mg / L;

[0061] BOD 5 54mg / L;

[0062] Total salt content (TDS) 2000mg / L;

[0063] (3) Permeate water volume and water quality:

[0064] Produced water 527.5m 3 / h;

[0065] Produced water quality: TDS<500mg / L, which meets the requirements of circulating water replenishme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com