Treating agent for garbage exudates and preparation method for treating agent

A technology of exudate and treatment agent, which is applied in the field of landfill exudate treatment agent and its preparation, and can solve problems such as damage to soil structure and physical and chemical properties, surface water or groundwater pollution, soil fertilizer retention, and water retention capacity decline. Achieve good purification effect and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

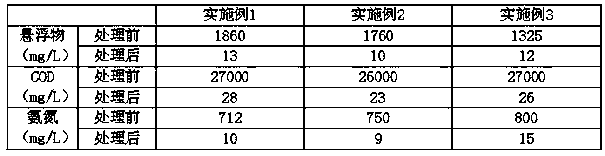

Examples

Embodiment 1

[0010] A treatment agent for garbage seepage, comprising the following raw materials in parts by weight: 18 parts of diatomite, 20 parts of potassium carbonate, 25 parts of aluminum oxide, 30 parts of ammonium oxalate tetraacetate, 10 parts of zingerone, 15 parts of octanal, 18 parts of quartz stone, 30 parts of calcium sulfate, 20 parts of calcium hydroxide, 22 parts of fatty wax alcohol, 10 parts of potassium hydroxide, 20 parts of methyl paraben, 11 parts of sodium percarbonate, diethyl 10 parts of sodium dithiocarbamate.

[0011] The preparation method of the above-mentioned treatment agent for garbage exudate comprises the following steps: diatomaceous earth, potassium carbonate, aluminum oxide, ammonium oxalate tetraacetate, zingiberone, octanal, quartz stone, calcium sulfate, hydroxide Calcium and fatty wax alcohol are mixed evenly, heated to 40°C, then add potassium hydroxide, methylparaben, sodium percarbonate, sodium diethyldithiocarbamate, stir evenly, and cool to r...

Embodiment 2

[0013] A treatment agent for garbage seepage, comprising the following raw materials in parts by weight: 19 parts of diatomite, 23 parts of calcium carbonate, 27 parts of aluminum oxide, 40 parts of ammonium oxalate tetraacetate, 15 parts of gingerone, Octanal 18 parts, quartz stone 23 parts, calcium sulfate 33 parts, calcium hydroxide 25 parts, fatty wax alcohol 28 parts, potassium hydroxide 15 parts, methylparaben 23 parts, sodium percarbonate 15 parts, diethyl 20 parts of sodium dithiocarbamate.

[0014] The preparation method of the above-mentioned treatment agent for garbage seepage comprises the following steps: diatomaceous earth, calcium carbonate, aluminum oxide, ammonium oxalate tetraacetate, zingiberone, octanal, quartz stone, calcium sulfate, hydroxide Calcium and fatty wax alcohol are mixed evenly, heated to 45°C, then add potassium hydroxide, methylparaben, sodium percarbonate, sodium diethyldithiocarbamate, stir evenly, and cool to room temperature.

Embodiment 3

[0016] A treatment agent for garbage seepage, comprising the following raw materials in parts by weight: 20 parts of diatomite, 25 parts of sodium carbonate, 28 parts of aluminum oxide, 50 parts of ammonium oxalate tetraacetate, 20 parts of gingerone, Octanal 20 parts, quartz stone 28 parts, calcium sulfate 35 parts, calcium hydroxide 28 parts, fatty wax alcohol 30 parts, potassium hydroxide 20 parts, methyl paraben 25 parts, sodium percarbonate 17 parts, diethyl 30 parts of sodium dithiocarbamate.

[0017] The preparation method of the above-mentioned treatment agent for garbage seepage comprises the following steps: diatomite, sodium carbonate, aluminum oxide, ammonium oxalate tetraacetate, zingiberone, octanal, quartz stone, calcium sulfate, hydroxide Calcium and fatty wax alcohol are mixed evenly, heated to 50°C, then add potassium hydroxide, methylparaben, sodium percarbonate, sodium diethyldithiocarbamate, stir evenly, and cool to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com