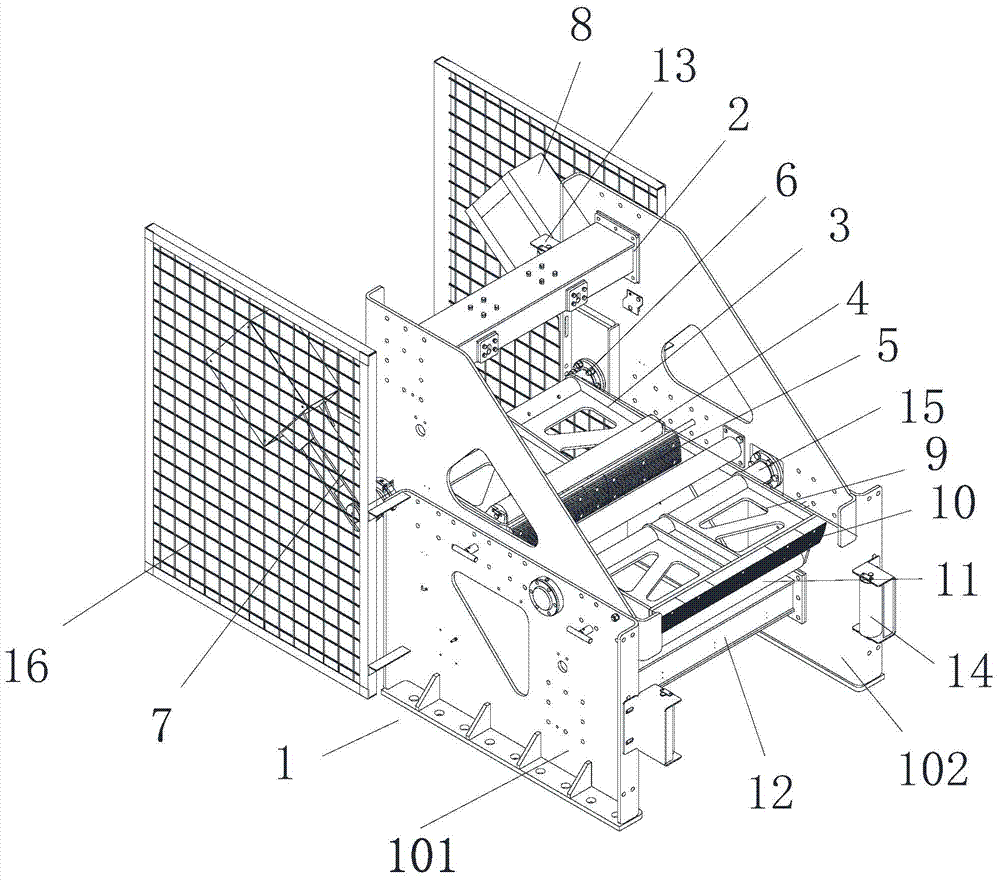

Belt-broken protective device with deceleration function

A protection device and belt-breaking technology, which is applied to the conveyor control device, transportation and packaging, conveyor objects, etc., can solve the problems of the impact of the conveyor fuselage frame, damage to the fuselage frame parts, etc., and achieve low production costs. , the effect of prolonging the service life and reducing the impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

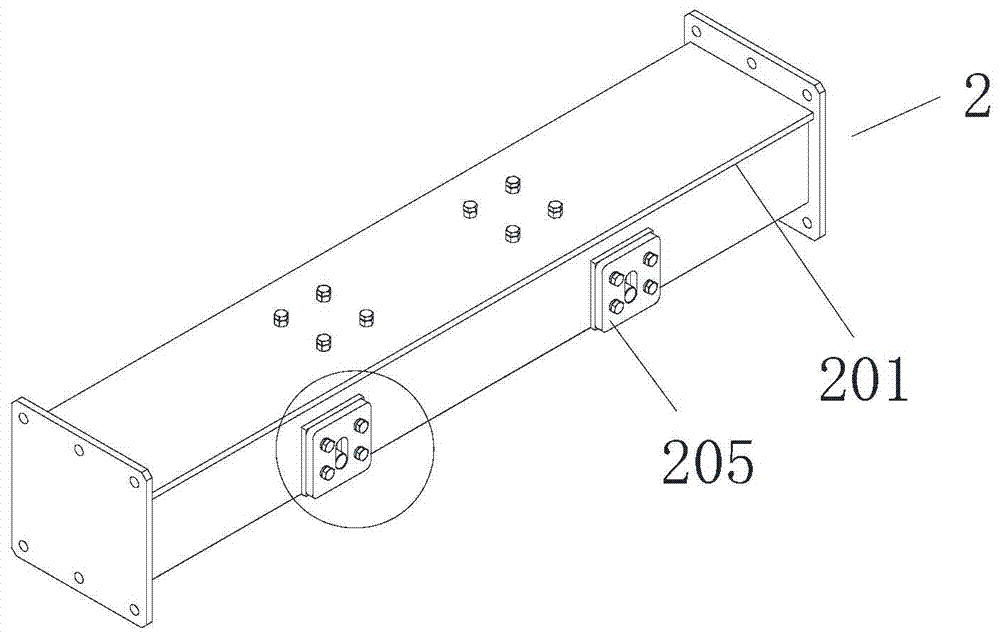

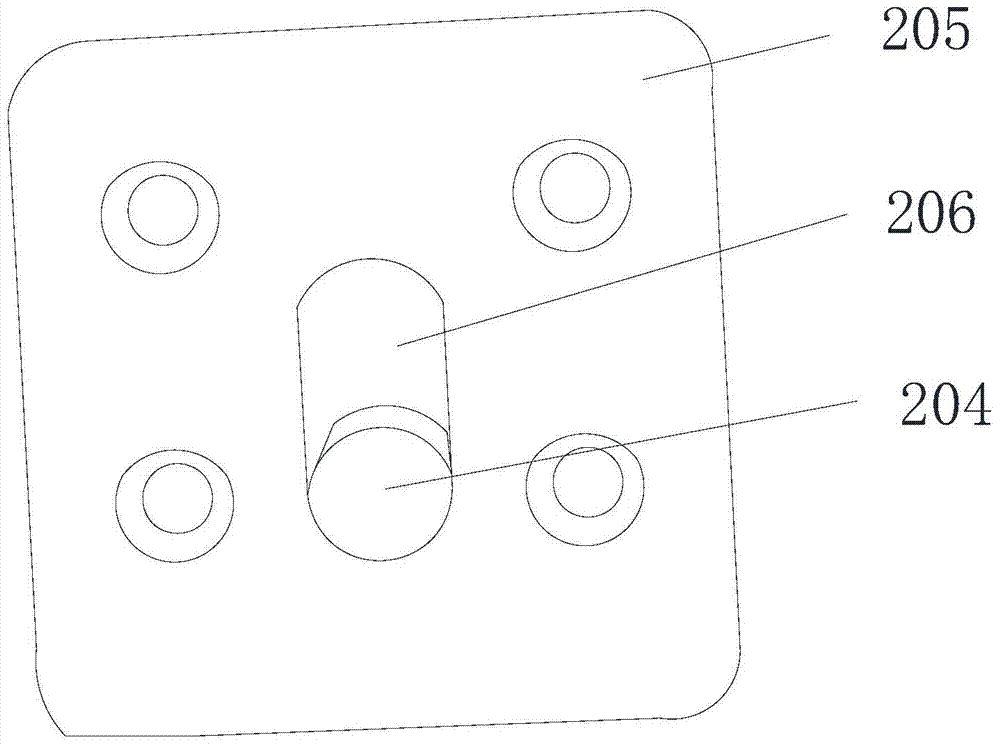

[0032] Implementation mode one: if Figure 4 and 5As shown, the damping mechanism includes an oil tank 207 arranged on the frame 1 and an oil cylinder 212 arranged between the stationary beam 201 and the movable beam 203. There is a gap at the bottom of the oil cylinder 212. An oil inlet 214 and an oil outlet 215 are arranged on the oil cylinder 212. The oil inlet 214 is located above the oil outlet 215. The oil inlet 214 passes through the oil supply pipeline 211 and the oil outlet of the oil tank 207. 208, the oil outlet 215 is connected to the oil return end 209 of the oil tank 207 through the oil return line 210, the oil return end 209 of the oil tank 207 is provided with a throttle valve, and the oil cylinder 212 is provided with a first piston rod 216, the first piston rod The bottom end of 216 is fixedly connected with the first adjusting disc 217, and the first adjusting disc 217 is provided with an oil seal 218 for plugging the above-mentioned oil inlet 214. The bott...

Embodiment approach 2

[0033] Implementation mode two: if Figure 4 and Figure 6 As shown, the damping structure includes an air pump 219 arranged on the frame 1 and an air cylinder 226 arranged between the stationary beam 201 and the movable beam 203. There is a gap at the bottom end of the cylinder 226. An air inlet 224 and an air outlet 225 are provided on the cylinder 226. The air inlet 224 is located above the air outlet 225. The air inlet 224 is connected to the air outlet 220 of the air pump 219 through an air supply pipeline 221. The air port 225 is connected to the air return end of the air pump 219 through the air return pipeline 223. The air return end of the air pump 219 is provided with a gas speed regulating valve, and the second piston rod 230 is arranged in the cylinder 226, and the bottom end of the second piston rod 230 is fixedly connected There is a second adjustment disc 228, and the second adjustment disc 228 is provided with an air seal 229 for blocking the above-mentioned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com