Cracking assistant for improving low-carbon olefin concentration

A technology of low-carbon olefins and catalytic cracking aids, which is applied in the fields of hydrocarbon cracking to produce hydrocarbons, cracking, catalytic cracking, etc., can solve the problem of low concentration of low-carbon olefins, etc. The effect of reducing coke yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

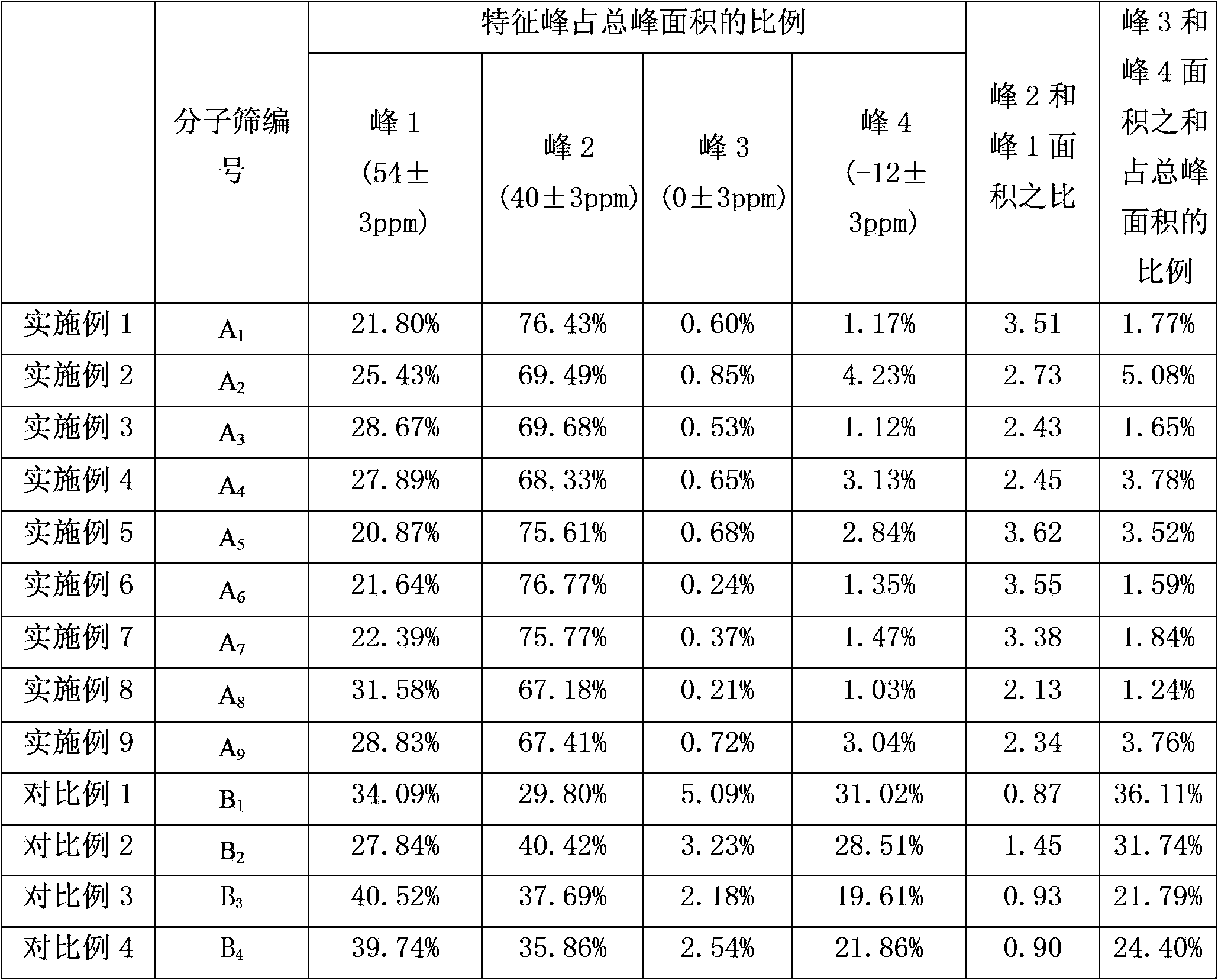

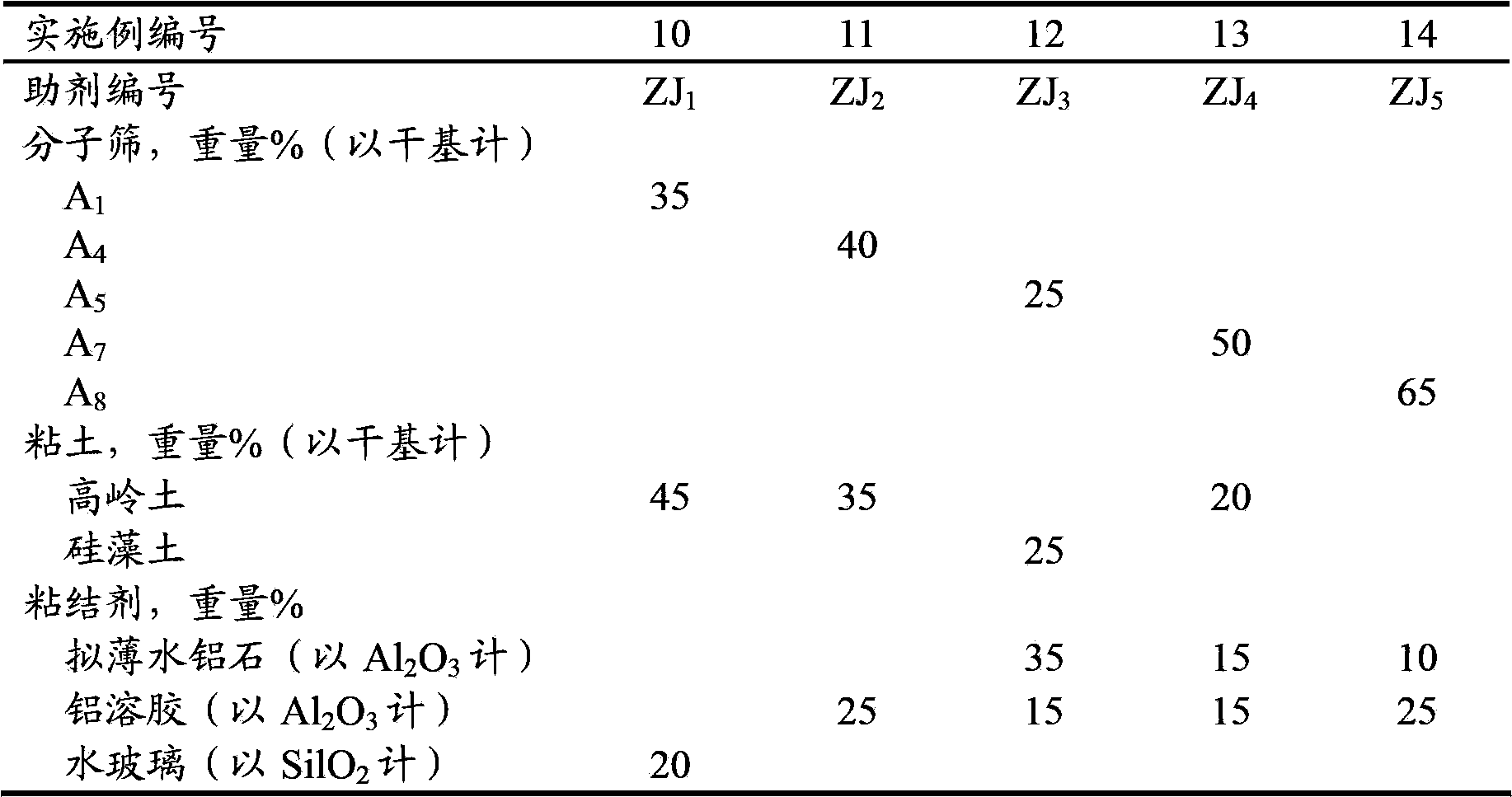

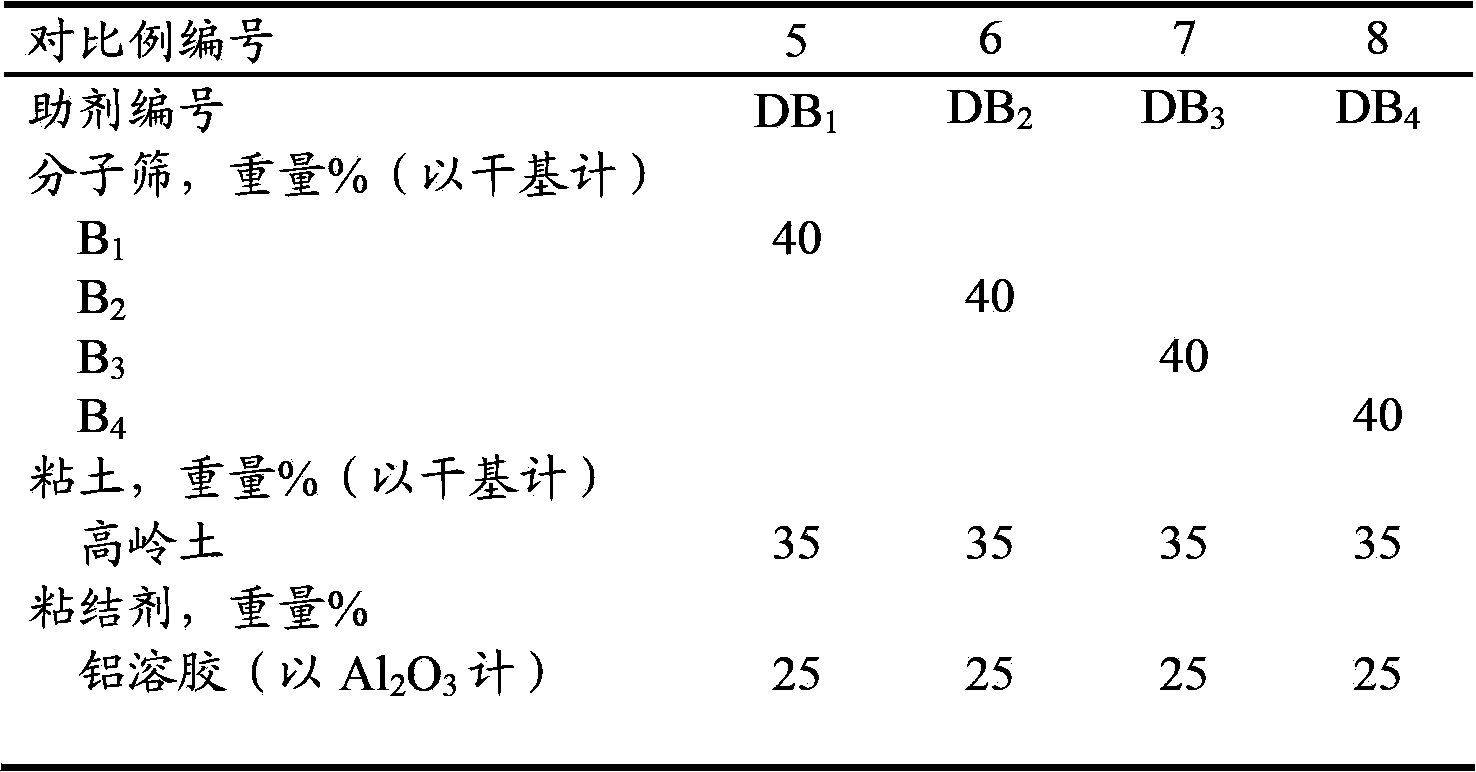

Examples

preparation example Construction

[0030] The preparation method of the phosphorus-containing and transition metal-containing molecular sieve provided by the present invention is characterized in that the raw powder of the β molecular sieve is placed in a temperature range from 200°C to 800°C through at least two non-overlapping temperature ranges from low to high After treatment to remove the templating agent, dealumination is followed by phosphorus and metal modification steps. Preferred steps include:

[0031] (1) The sodium-type β molecular sieve is exchanged with ammonium to make the Na on the molecular sieve 2 The O content is less than 0.2% by weight;

[0032] (2) After drying the molecular sieve obtained in step (1), treat it at a temperature range of 200-400°C for at least 0.5 hours, and then heat it up to a temperature range of 500-800°C within at most 2 hours and treat it for at least 0.5 hours to remove the template agent;

[0033] (3) Treating the product obtained in step (2) with a dealuminatio...

Embodiment 1

[0053] Beta zeolite (Naβ, produced by Qilu Catalyst Factory, SiO 2 / Al 2 o 3 =25, sodium oxide content 4.5% by weight, the same below) with NH 4 Cl solution exchange wash to Na 2 The O content is lower than 0.2% by weight, and the filter cake is obtained by filtration; dried, and the obtained sample is roasted at 350°C for 2 hours, and then heated to 550°C for 4 hours to remove the template agent; take 100g (dry basis) of the above-mentioned molecular sieve and add water Prepare a molecular sieve slurry with a solid content of 10% by weight, add 20g of oxalic acid during stirring, heat up to 80°C and stir for 1h, filter and wash until the filtrate is neutral; add water to the filter cake and beat to obtain a molecular sieve slurry with a solid content of 40% by weight, and mix 6.8gH 3 PO 4 (Concentration 85%) and 3.2gCu(NO 3 ) 2 ·3H 2 O was dissolved in 30 g of water, mixed with the molecular sieve slurry, impregnated and dried; the obtained sample was calcined at 550° ...

Embodiment 2

[0056] beta zeolite with NH 4 Cl solution exchange wash to Na 2 The O content is lower than 0.2% by weight, and the filter cake is obtained by filtration; dried, and the obtained sample is roasted at 150°C for 2 hours, then heated to 350°C for 2 hours for 30 minutes, and then heated to 500°C for 4 hours for 30 minutes. Template removal agent: Take 100g of the above-mentioned molecular sieve (dry basis) and add water to prepare a molecular sieve slurry with a solid content of 10% by weight, add 10g of fluosilicic acid during stirring, heat up to 60°C and stir for 1h, filter and wash until the filtrate is neutral; add water to the filter cake Beating to obtain a solid content of 40% by weight molecular sieve slurry, 11.8gH 3 PO 4 (concentration 85%) with 6.3gCuCl 2 Dissolved in 90g of water, mixed with filter cake, soaked and dried; the obtained sample was roasted at 550°C for 2 hours, namely the modified β molecular sieve provided by the present invention.

[0057] Elementa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com