Large image plane high resolution optical lens

A high-resolution, optical lens technology, applied in optics, optical components, installation, etc., can solve problems such as vignetting, failure to reach large chips, and high price, and achieve the effect of good process performance and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

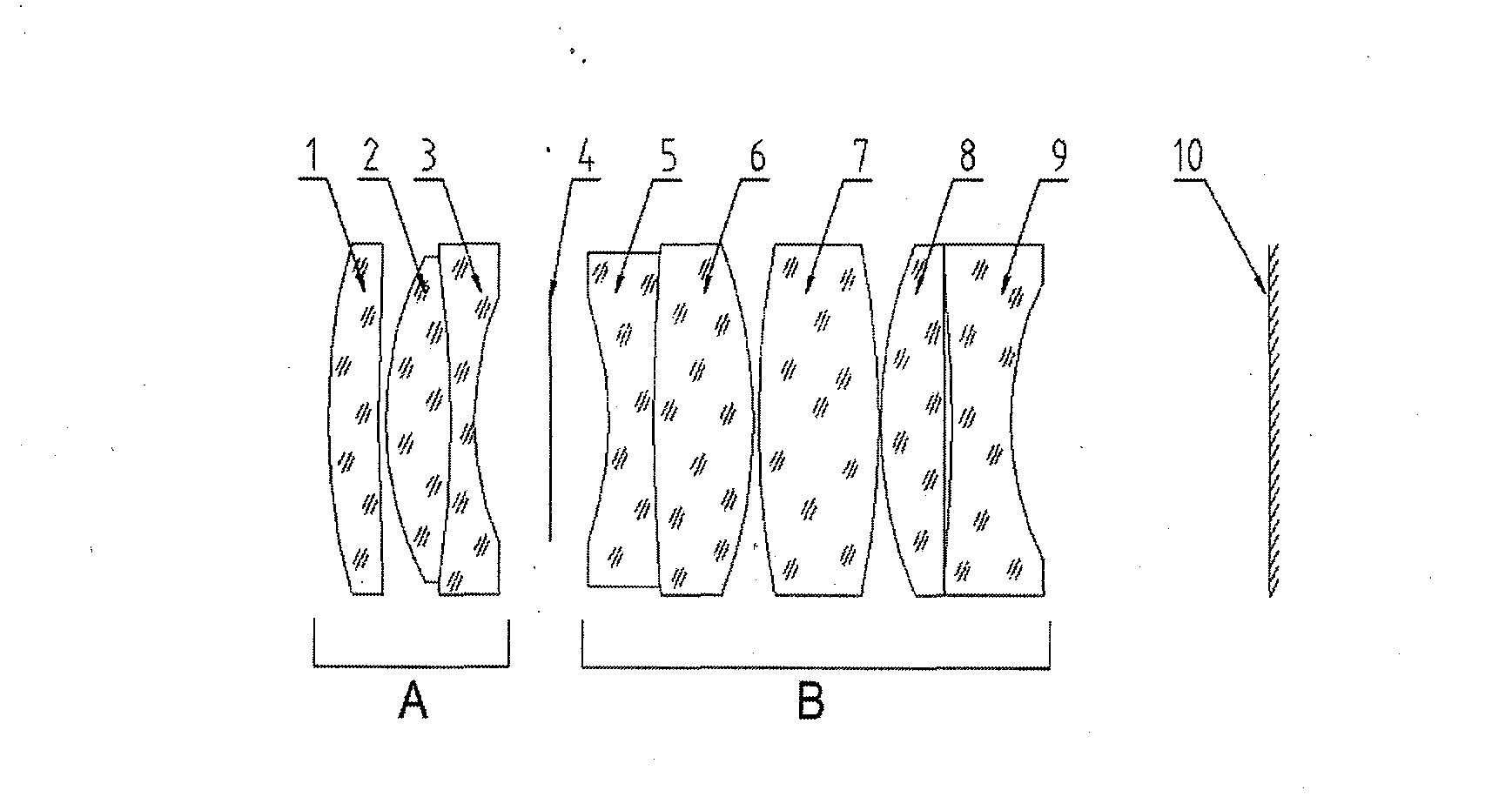

[0026] 1. If figure 1 As shown, a large image surface high-resolution optical lens described in this patent, from left to right is: concave-convex lens 1, biconvex lens 2, biconcave lens 3, biconcave lens 5, biconvex lens Lens 6', biconvex lens 7, plano-convex lens 8 and biconcave lens 9.

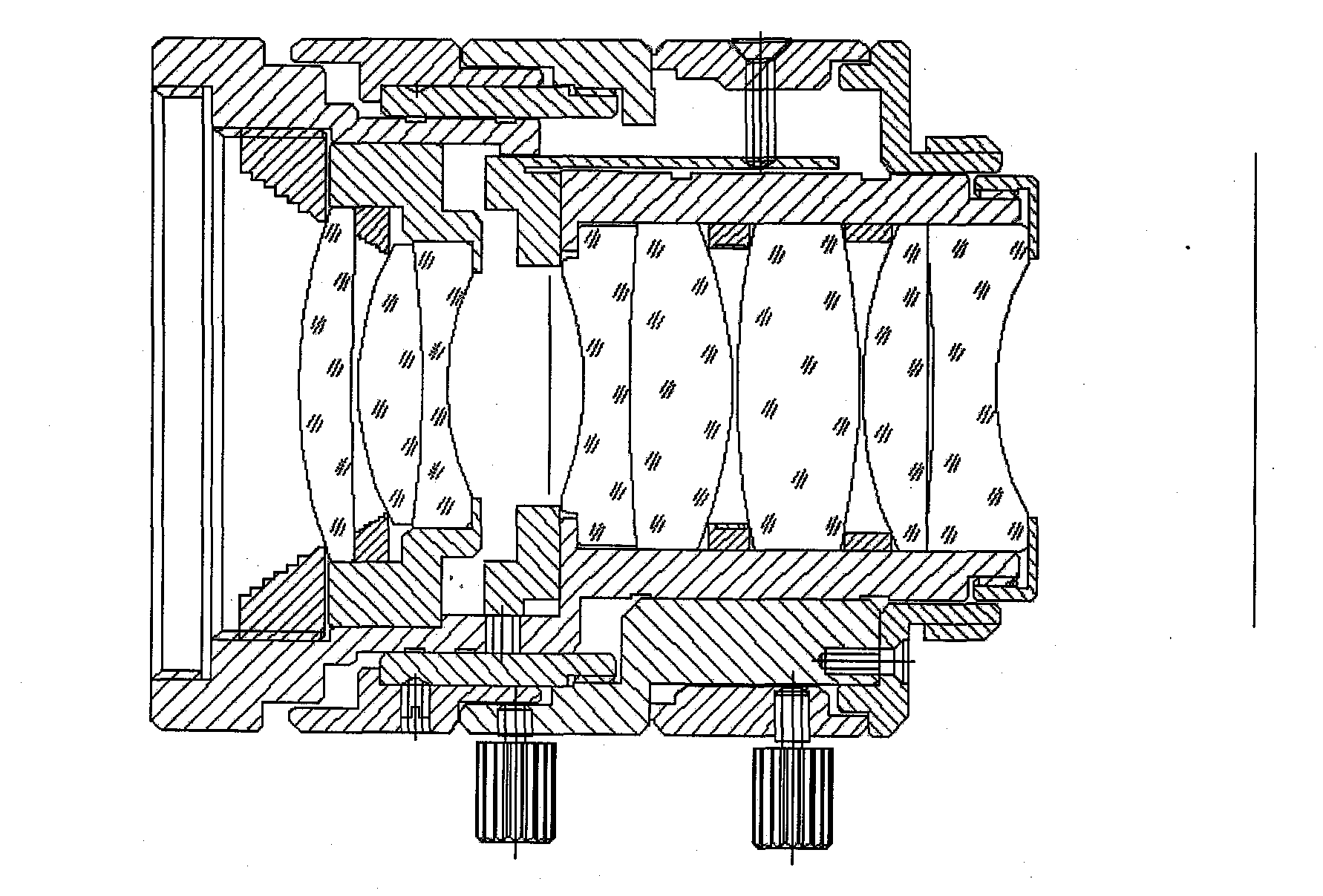

[0027] 2. If figure 2 As shown, a large image surface high-resolution optical lens described in this patent is characterized in that a gasket is arranged between the cemented lens composed of the concave-convex lens 1, the biconvex lens 2 and the biconcave lens 3, Make the center interval between the two be 0.34mm, another gasket is provided between the cemented lens composed of biconcave lens 5 and biconvex lens 6 and biconvex lens 7, so that the center interval between the two is 1.52mm A gasket is also provided between the biconvex lens 7 and the plano-convex lens 8, so that the center interval between the two is 0.25mm, and the plane contact between the plano-convex lens 8 and the bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com