CO boiler having denitration function

A boiler and functional technology, applied in the field of CO boilers with denitrification function, can solve the problems of low flue gas denitrification efficiency, high investment, uneven mixing and land occupation of denitrification equipment, etc., to improve heat utilization efficiency, simplify equipment structure, save The effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

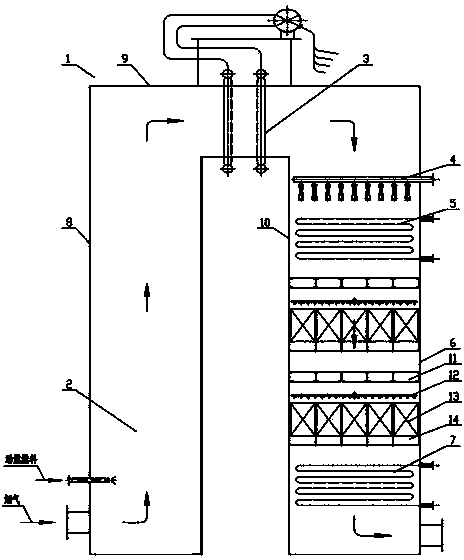

[0028] Depend on figure 1 As shown, the present invention provides a CO boiler with denitrification function. The boiler includes a flue 1, a combustion chamber 2, a steam drum 3, an evaporation section 5 and an economizer section 7, and the flue includes a first Vertical flue 8, horizontal flue 9 and the second vertical flue 10, the two ends of the horizontal flue 9 communicate with the top of the first vertical flue 8 and the second vertical flue 10 respectively, the combustion chamber 2 is set in the first vertical flue 8, the steam drum 3 is set in the horizontal flue 9, the evaporation section 5 and the economizer section 7 are set in the second vertical flue 10, wherein the boiler also It includes an ammonia injection mixing mechanism 4 and a denitration reactor 6, the ammonia injection mixing mechanism 4 is arranged in the second vertical flue 10 above the evaporation section 5, and the denitration reactor 6 is located in the evaporation section 5 and the economizer sec...

Embodiment 2

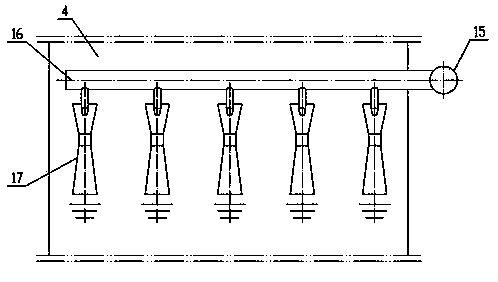

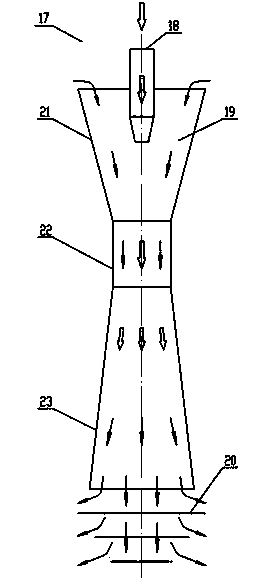

[0031] In the boiler of the present invention, the ammonia injection mixing mechanism 4 includes an ammonia injection main pipe 15, an ammonia injection branch pipe 16 and an ammonia injection element 17. 15, and the other end is a closed structure; the ammonia injection element 17 includes a nozzle 18, a diffuser 19 and a splash plate 20, and the lower surface of the ammonia injection branch pipe 16 is connected to the ammonia injection element 17 through the nozzle 18. The diffuser 19 includes a constriction section 21 , a throat 22 and an expansion section 23 from top to bottom. Among them, the contraction angle of the contraction section is 15°-30°, the expansion angle of the expansion section is 10°-20°, the length of the throat is 1-3 times the diameter of the throat, and the distance between the splash plate and the horizontal section of the outlet of the expansion section is the length of the throat 80% to 120% of 80% to 120% of the splash plate 4; the splash plate 4 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contraction angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com