Sewage total-nitrogen processing apparatus and method thereof

A nitrogen treatment and sewage technology, applied in the field of sewage total nitrogen treatment devices, can solve the problems of insufficient proportion of raw water carbon source and nitrogen source, no denitrification anaerobic unit, and low denitrification efficiency, and achieve high total nitrogen removal efficiency, Reduce the amount of aeration and achieve the effect of sludge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] At first the device provided by the present invention is illustrated in conjunction with the accompanying drawings:

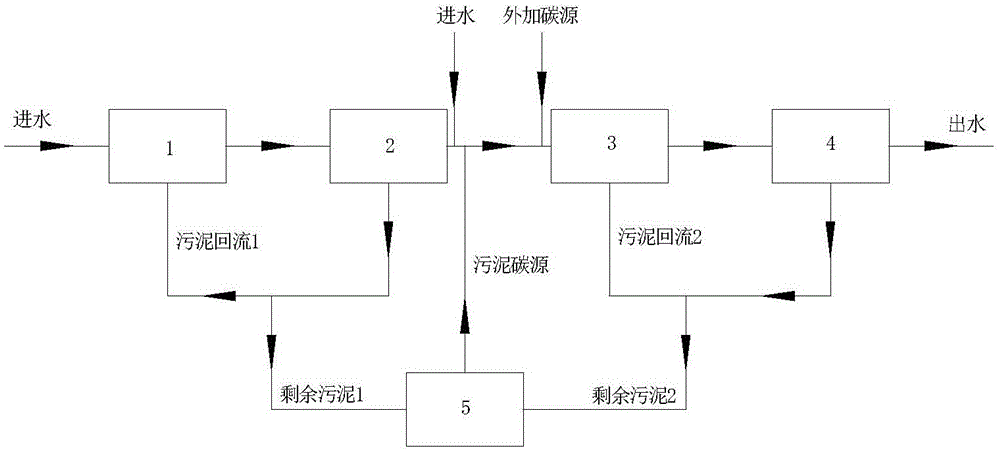

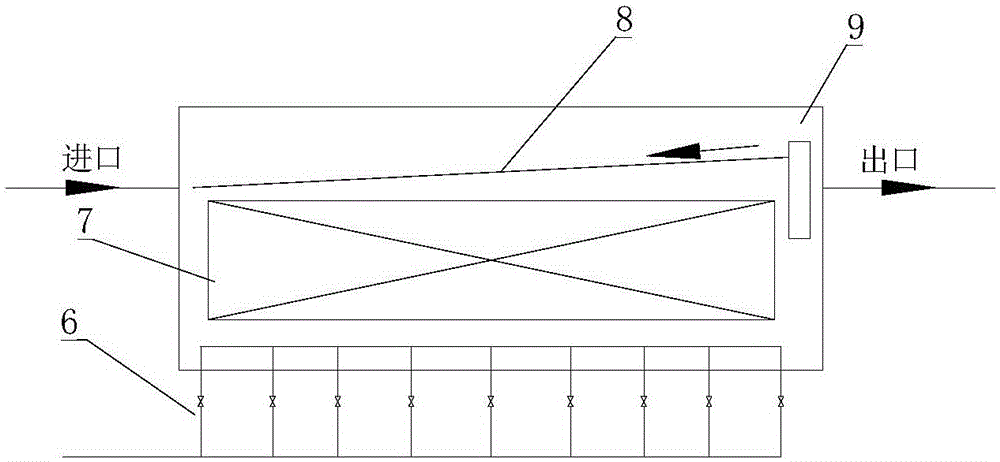

[0039] Such as figure 1 , figure 2 As shown, the sewage total nitrogen treatment device provided by the present invention includes the first biochemical reaction tank 1, the first settling tank 2, the second biochemical reaction tank 3, the second settling tank 4, the sludge carbon source converter 5 and supporting Sludge return control system; wherein, the first biochemical reaction tank 1, the first settling tank 2, the second biochemical reaction tank 3 and the second settling tank 4 are arranged in sequence, and the first biochemical reaction tank 1 and the second biochemical reaction tank 3 There are several aeration devices 6, fillers 7, diversion tanks 8 and air level lifters 9 that can be controlled by individual valves respectively, wherein the water inlet end of the diversion tanks 8 is connected to the corresponding air level riser 9 Outlet...

Embodiment 2

[0043] The sewage total nitrogen treatment device of this embodiment is the same as that of Embodiment 1, so it will not be described again.

[0044] The method provided by the present invention is described in detail below in conjunction with accompanying drawing:

[0045] Using the present invention to treat oil refinery wastewater in a plant, with a water volume of 250m 3 / h, COD 200mg / L, total nitrogen 90mg / L, ammonia nitrogen 45mg / L, 200m 3 / h Sewage water enters through the inlet of the first biochemical reaction tank 1, adjust the switches of the aeration device 6, and control the first 1 / 3 area of the first biochemical reaction tank 1 to be an anaerobic zone, and the dissolved oxygen is 0.5-1.0mg / L for For denitrification reaction, the last 2 / 3 area is an aerobic area, and the dissolved oxygen is 3.0-4.0mg / L for nitrification reaction. The air liquid level riser 9 returns 400% of the sewage sludge mixture at the outlet of the first biochemical reaction tank 1, and ...

Embodiment 3

[0047] The sewage total nitrogen treatment device of this embodiment is the same as that of Embodiment 1, so it will not be described again.

[0048] The method provided by the present invention is described in detail below in conjunction with accompanying drawing:

[0049] Using the present invention to treat chemical sewage, the water volume is 200m 3 / h, COD 200mg / L, total nitrogen 40mg / L, ammonia nitrogen 30mg / L, 150m 3 / h Sewage water enters through the inlet of the first biochemical reaction tank 1, adjust the switches of the aeration device, and control the first 1 / 2 area of the first biochemical reaction tank 1 as an anaerobic zone, and the dissolved oxygen is 0.5-1.0mg / L for reaction Nitrification reaction, the latter 1 / 2 area is an aerobic area, and the dissolved oxygen is 3.0-4.0mg / L for nitrification reaction. The air liquid level riser 9 returns 300% of the sewage sludge mixture at the outlet of the first biochemical reaction tank 1, and the effluent enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com