Multi-flame burner and method for heating a workpiece

A burner and combustion head technology, which is applied in the combination of multiple burners, combustion methods, burners, etc., can solve the problems of expensive safety precautions and achieve the effects of weight reduction, less maintenance requirements, and low downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

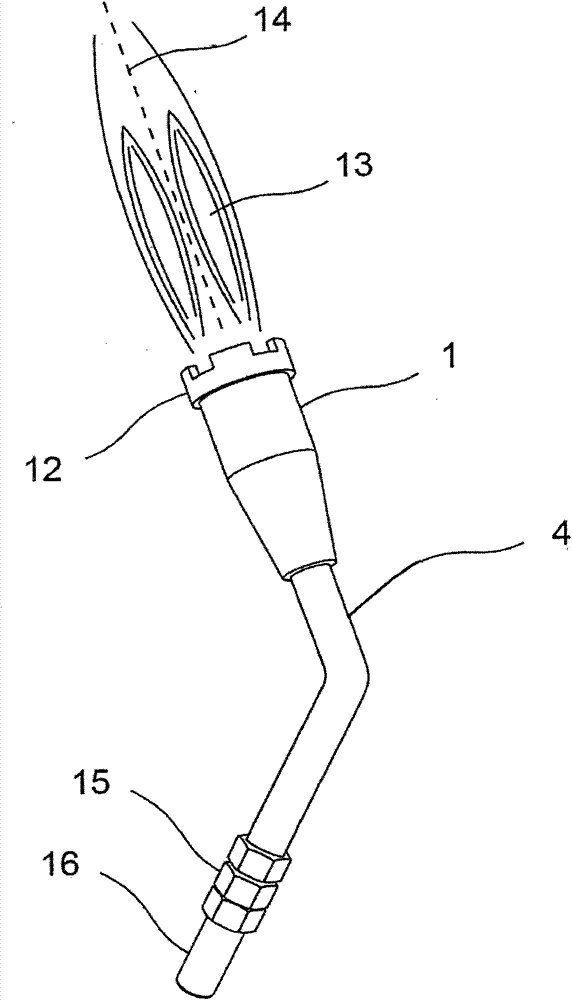

[0045] figure 1 A schematic view of a combustion head 1 is shown with a nozzle ring 12 which can have any desired number of preferably centrally arranged nozzles through which fuel can escape. Ignition of the fuel produces a combustion flame 13 which extends along a flame axis 14 . Via an offset connecting pipe 4 together with a threaded joint 15 and a connecting nozzle 16, the combustion head 1 can be connected to the feed line. For example, the connection nozzle 16 is welded to the feed line.

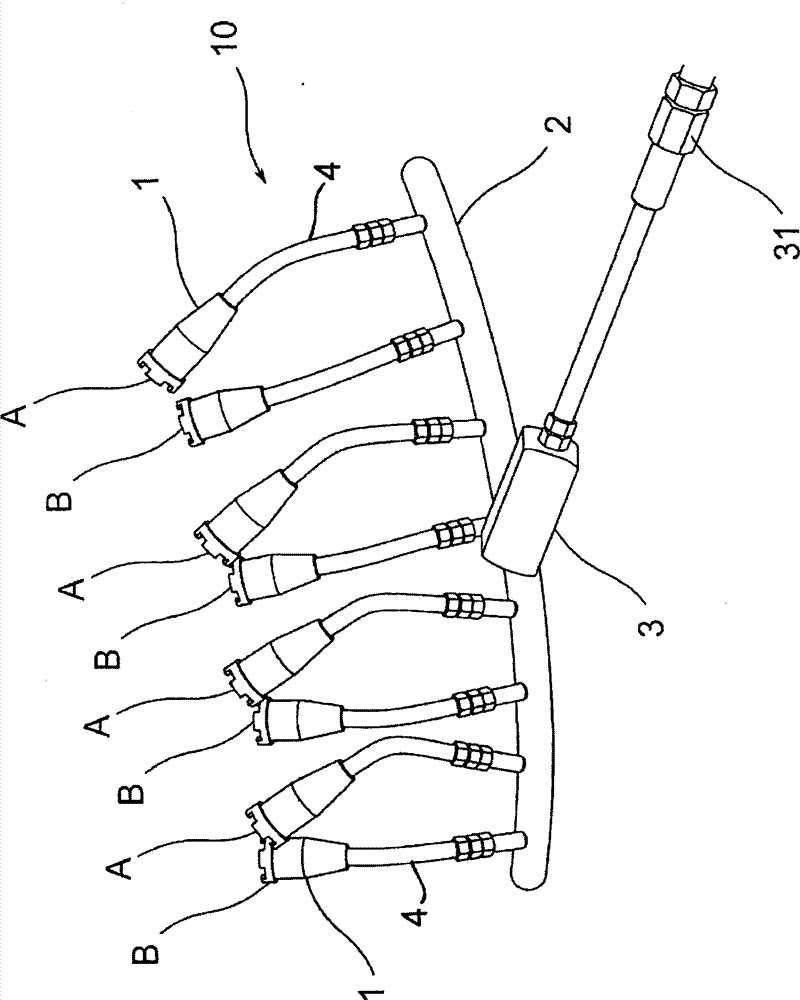

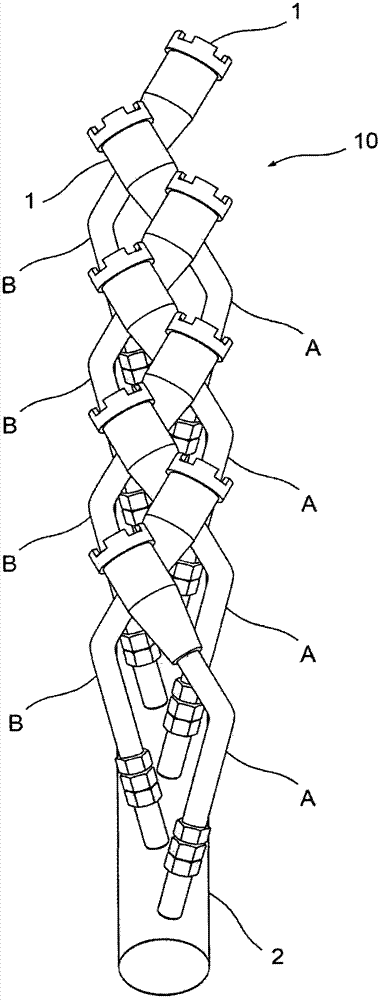

[0046] figure 2 A schematic side view of a multi-flame burner, generally designated 10 , according to a particularly preferred embodiment of the present invention is shown. The multi-flame burner 10 comprises a total of eight combustion heads 1, each of which is accompanied by a respective offset connecting pipe 4, not all of which are provided with a reference number. The combustion heads 1 are here combined into groups A and B of combustion heads. The combustion heads A of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com