Preparation method of CdTe/CdS/ZnS/SiO2 quantum dot

A reactor and solution technology, applied in the field of nanomaterials, can solve the problems of complex operation, decreased quantum yield, time-consuming, etc., and achieve the effect of rapid synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Tellurium powder, NaBH 4 、Cd(Ac) 2 2.5 H 2 O, ZnSO 4 ·7H 2 O, NaS 7H 2 O. Tetraethyl orthosilicate (Sinopharm Chemical Reagent Co., Ltd.); Mercaptopropionic acid (98%, Aladdin Reagent Co., Ltd.).

[0025] This patent examines the effect of reaction ratio (Example 1-7), sodium sulfide solution drop rate (Example 6-9,), reflux temperature and reflux time (Example 8, 10-17) on CdTe / CdS / ZnS / SiO 2 The optical properties of QDs and the impact of particle size, specific implementation schemes and experimental results are shown in Table 1 and Table 2, respectively.

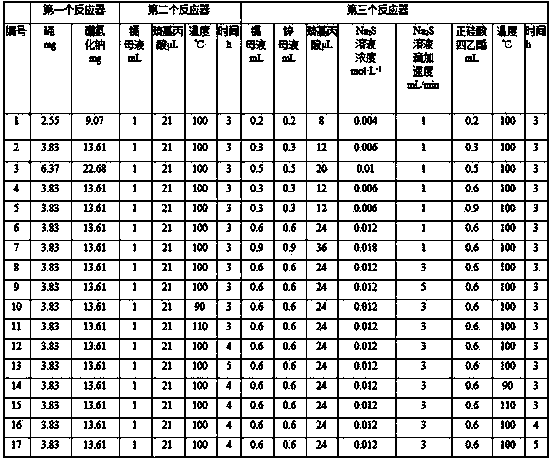

[0026] Table 1

[0027]

[0028] Table 2

[0029]

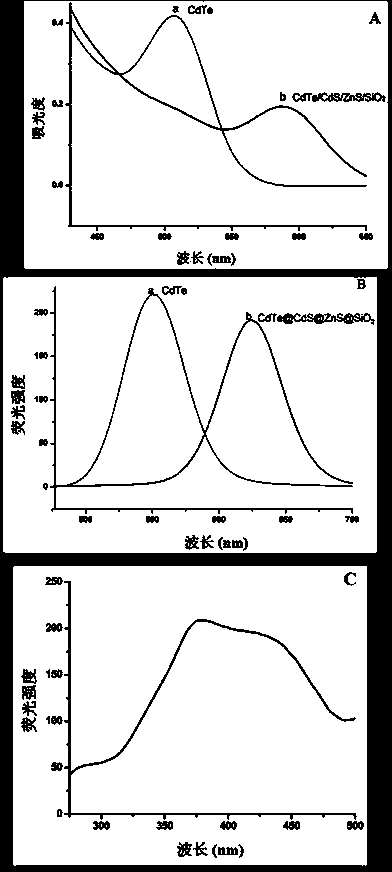

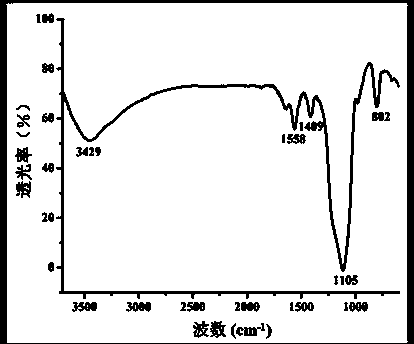

[0030] The above results prove that CdTe / CdS / ZnS / SiO with excellent performance can be synthesized by optimizing the experimental conditions. 2 QDs. The QDs synthesized under the optimal conditions (Example 12) have the characteristics of high quantum yield, narrow half-maximum width, and small particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com