Preparation method of organosilicone modified hydroxy acrylic resin aqueous dispersion

A hydroxyacrylic acid, silicone technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor storage stability of acrylic emulsions, and achieve the effect of saving dosage, excellent water and corrosion resistance, and good hydrophilic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

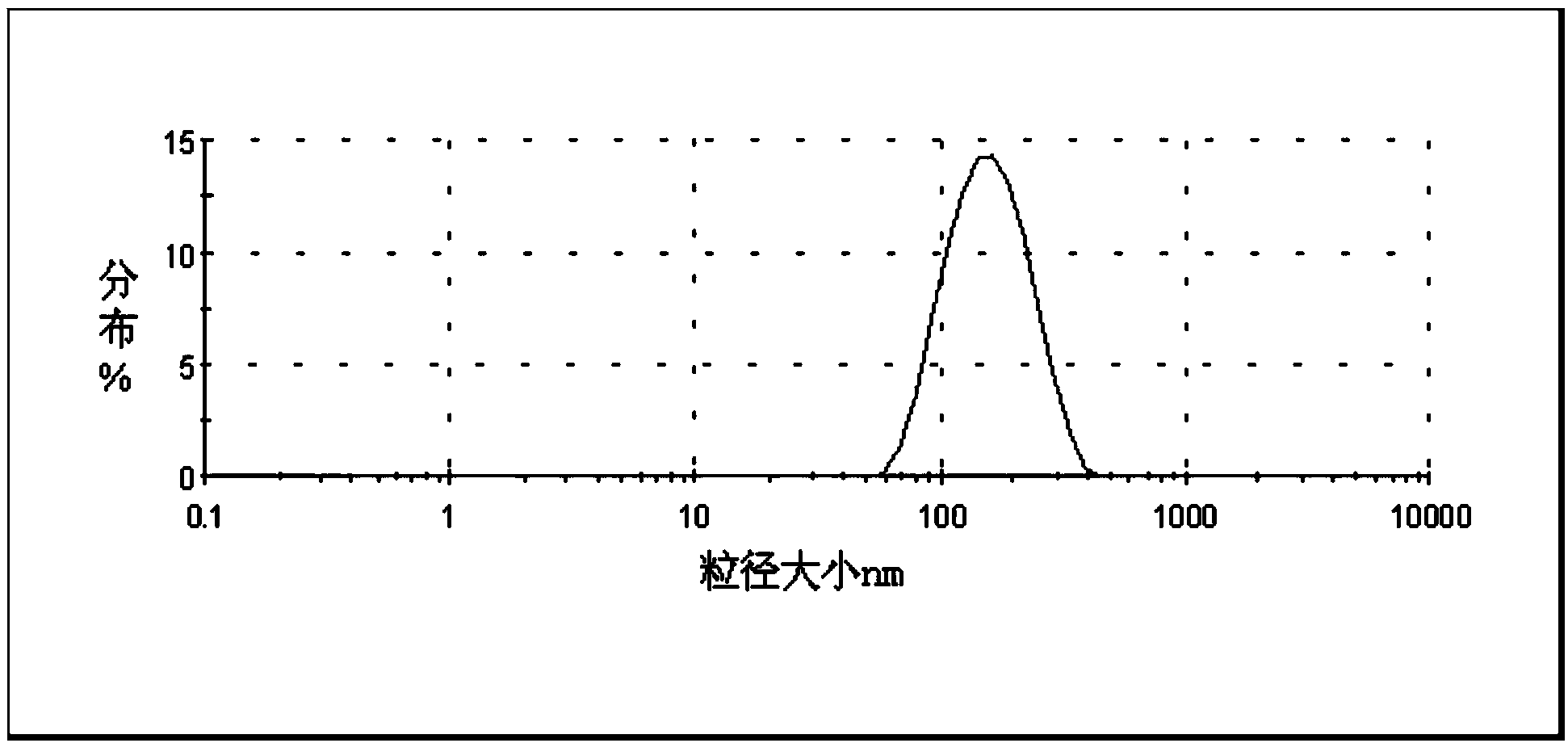

[0052] (1) Preparation of silicone-modified hydroxyacrylic acid aqueous dispersion

[0053] In a reactor with stirring, cooling and heating devices, add 90g propylene glycol butyl ether, 28.35g tertiary carbonic acid glycidyl ester and 2.4g dodecyl mercaptan, and raise the temperature to 130°C while blowing nitrogen. After reaching a constant temperature, start to add dropwise, which is composed of 42.9g styrene, 69.9g butyl acrylate, 51.9g methyl methacrylate, 75g hydroxypropyl methacrylate, 10.2g acrylic acid, 9.0g tert-amyl peroxyacetate The monomer mixed solution a is controlled to be added dropwise at about 180min. After dropping, start to drop the monomer mixed solution b composed of 6.0g vinyltriisopropoxysilane, 0.3g tert-amyl peroxyacetate, and 24.0g propylene glycol butyl ether, and make it drop in about 10 minutes. After dropping, finally add the monomer mixed solution c composed of 11.4g of acrylic acid and 0.3g of tert-amyl peroxyacetate dropwise, so that the dro...

Embodiment 2

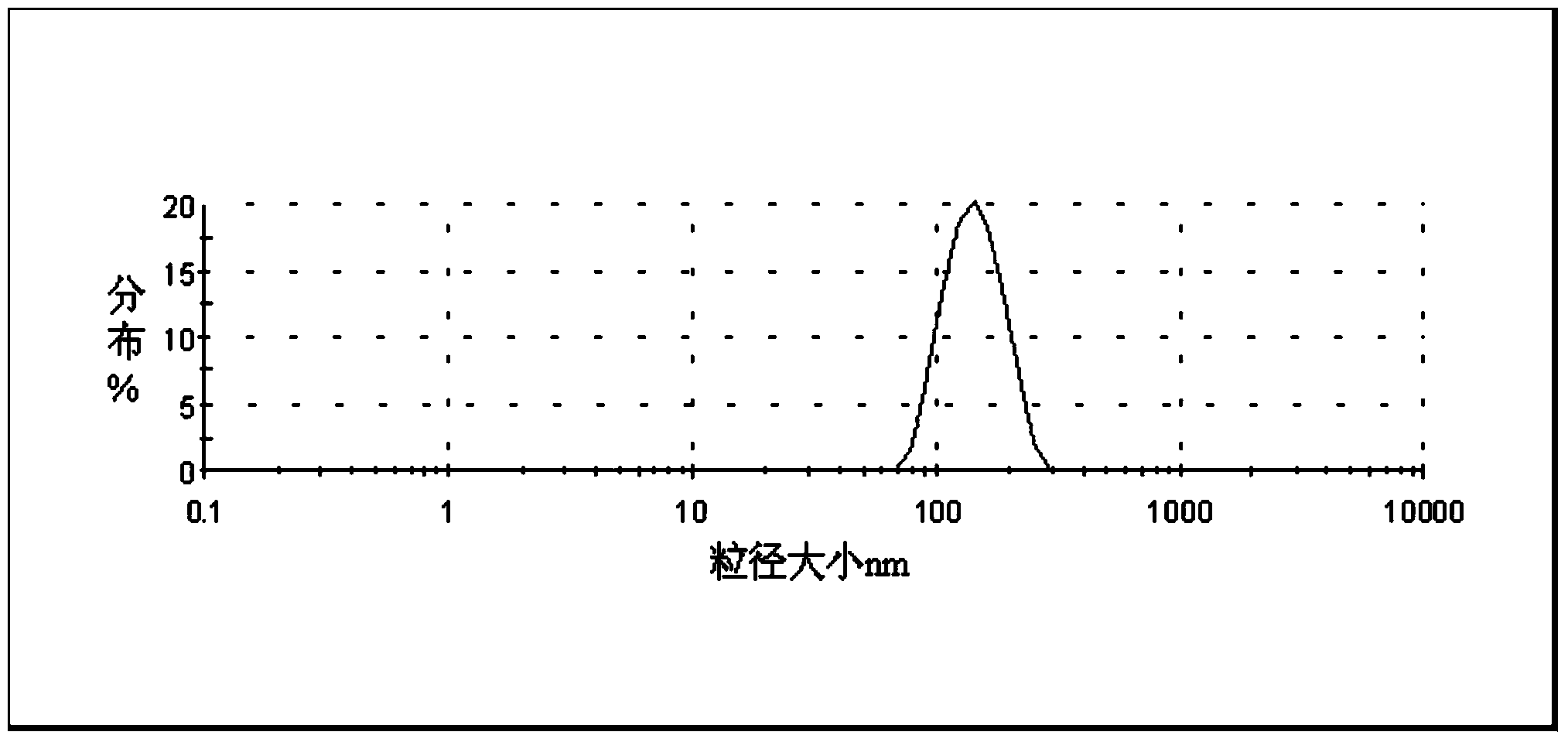

[0062] (1) Preparation of silicone-modified hydroxyacrylic acid aqueous dispersion

[0063] In the reactor with stirring, cooling and heating devices, add 96g propylene glycol methyl ether acetate, 25.2g glycidyl tert-carbonate and 2.4g mercaptoethanol, and heat up to 130°C while blowing nitrogen. After reaching a constant temperature, start dropping 45.9g styrene, 63.9g butyl acrylate, 52.8g methyl methacrylate, 72g hydroxyethyl methacrylate, 16.2g methacrylic acid, 9.0g tert-amyl peroxyacetate The monomer mixed solution a is controlled to be added dropwise at about 180min. After dropping, start to add 9.0g of vinyltriethoxysilane, 0.6g of tert-amyl peroxyacetate, and 24g of propylene glycol butyl ether monomer mixed solution b, and make it drop in about 10 minutes. After dropping, start to add dropwise the monomer mixed solution c of 11.4g of acrylic acid and 0.3g of tert-amyl peroxyacetate, so that the dropwise addition is completed in about 10 to 15 minutes. After drippi...

Embodiment 3

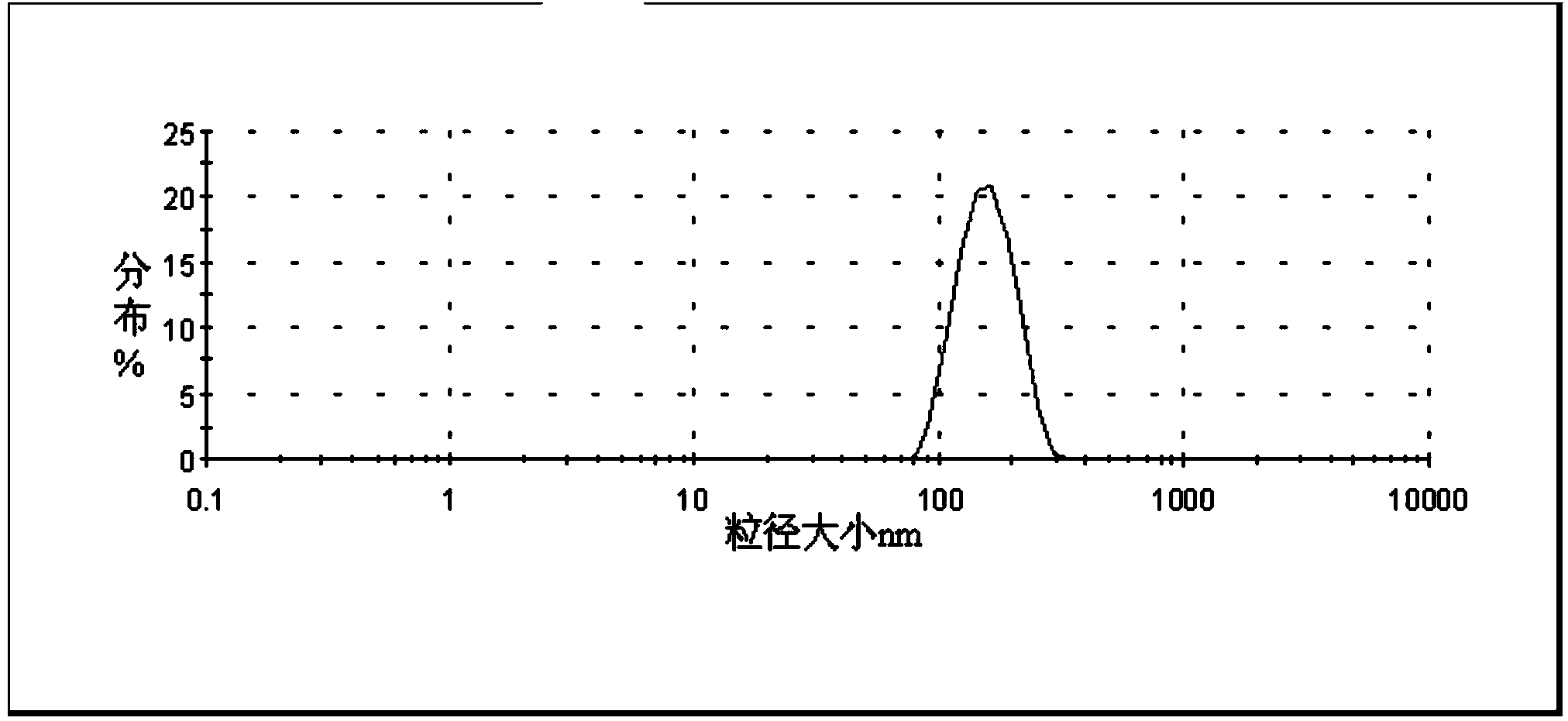

[0071] (1) Preparation of silicone-modified hydroxyacrylic acid aqueous dispersion

[0072]In the reactor with stirring, cooling and heating devices, add 84g butyl acetate, 31.5g glycidyl tert-carbonate and 2.4g dodecyl mercaptan, and raise the temperature to 130°C while blowing nitrogen. After reaching a constant temperature, start to add dropwise, which is composed of 37.5g styrene, 72.9g butyl acrylate, 55.5g methyl methacrylate, 75g hydroxyethyl methacrylate, 9.3g acrylic acid, 9.0g tert-amyl peroxyacetate The monomer mixed solution a is controlled to be added dropwise at about 180min. After dropping, then start by dripping 9.0g vinyl tris (beta-methoxyethoxy) silane, 0.3g tert-amyl peroxyacetate, the monomer mixed solution b that 30.0g propylene glycol butyl ether forms, make it in About 10 minutes to finish dripping. After dropping, start to add dropwise the monomer mixed solution c of 10.5g of acrylic acid and 0.45g of tert-amyl peroxyacetate, so that the dropwise add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com