Ultrafiltration membrane separation method for obtaining royal jelly major protein and active filtrate in royal jelly

The technology of a royal jelly main protein and a separation method is applied in the field of separating the royal jelly main protein and active filtrate from royal jelly, which can solve the problems of no advantages and difficult optimization conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] MRJPs ultrafiltration separation and concentration in fresh royal jelly in embodiment 1

[0054] 1. Using ultrafiltration membrane to separate and concentrate MRJPs from fresh royal jelly

[0055] Principle: Since royal jelly usually contains 11%-14.5% royal jelly crude protein and 20%-30% sugar, the molecular weight of royal jelly main protein is 49-87kDa, and the molecular weight of sugar is 150-200. The advanced ultrafiltration membrane can efficiently intercept royal jelly main protein, and can effectively separate it from sugar and other low molecular weight components to achieve the purpose of purification and concentration.

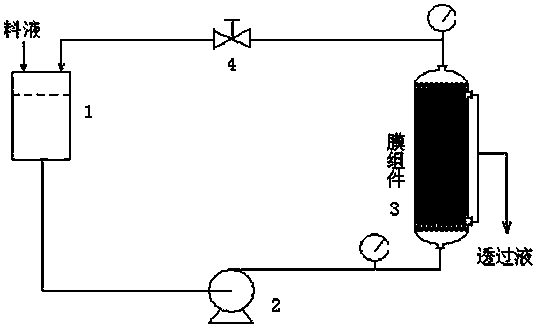

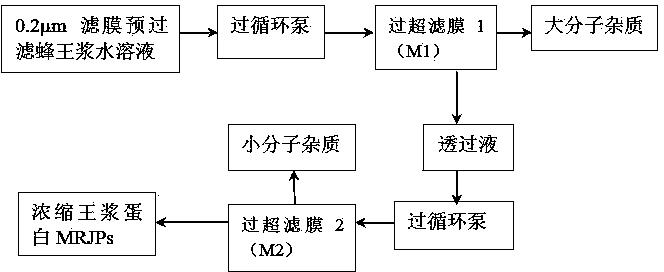

[0056] Operation process: use figure 1 The ultrafiltration device shown (feed liquid tank 1, circulating pump 2, membrane module 3, and pressure regulating valve 4 are connected in sequence), press figure 2 Method flow, operation. Weigh 50g of fresh royal jelly, mix according to a certain proportion of material and water, fully stir at 4...

Embodiment 2

[0082] Example 2 Detection of Ultrafiltration Separation of MRJPs Products

[0083] 1. SDS-PAGE detection of MRJPs products separated by ultrafiltration

[0084] Fresh royal jelly was obtained and separated by ultrafiltration under optimal conditions to obtain MRJPs products for SDS-PAGE electrophoresis detection. The concentration of the electrophoresis stacking gel was 5%, the concentration of the separating gel was 12%, the electrophoresis buffer system was Tris-glycine buffer, and the protein sample loading volume was 20 μL / well.

[0085] ① Preparation of separation gel: 12% separation gel (5mL): 1.6mL ddH20, 2.0mL 30% acrylamide, 1.3mL1.5mol / LTris-HCL (pH8.8), 50μL 10% SDS, 50μL 10% ammonium persulfate, 4μL TEMED;

[0086] ② Prepare stacking gel: 5% stacking gel (1mL): 0.68mL ddH20, 0.34mL 30% acrylamide, 0.26mL 1.0mol / LTris-HCL (pH6.6), 10μL 10% SDS, 10μL 10% ammonium persulfate, 4μL TEMED;

[0087] ③Sampling: Mix 2×protein buffer with the same amount of protein sample...

Embodiment 3

[0103] 10-HDA and total sugar recovery in the filtered liquid of fresh royal jelly in embodiment 3

[0104] 1. Recovery of 10-HDA and total sugar in the filtrate

[0105] Under optimal conditions, the ultrafiltration membrane system was used to process the concentrated MRJPs of fresh royal jelly to obtain filtrate samples. First use a rotary evaporator to concentrate the filtrate at 40°C (30 mL of concentrated sample can be obtained per 100 mL of filtrate), and then freeze-dry in a vacuum to obtain a lyophilized powder.

[0106] 2. Determination of recovery rate of fresh royal jelly and ultrafiltration liquid 10-HDA

[0107] Referring to the 10-HDA determination method in GB9697-2008, the 10-HDA content of the lyophilized product of the filtrate and the fresh royal jelly were measured. The results (Table 4) showed that the 10-HDA contents of the lyophilized product of the fresh royal jelly and the filtrate were respectively 1.13% and 0.93%. follow the next

[0108] Calcula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com