Method for preparing tungsten disulfide nano sheet

A technology of nano-flakes and tungsten disulfide, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as high temperature, vacuum degree, and complicated operation process, and achieve easy operation, simple experimental methods, and environmental pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

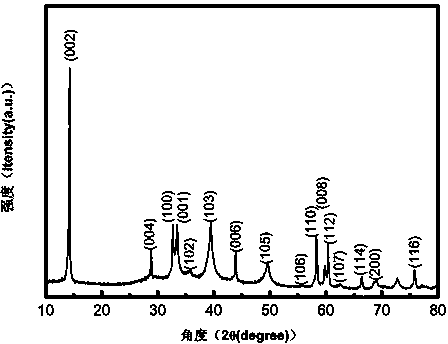

[0016] In a high-pressure reactor with a volume of 50mL, add a certain amount of Li 2 CO 3 Powder, direct commercially purchased WS 2 Powder and 40mL organic solvent benzyl alcohol solution, put the autoclave at 200 o The solvothermal reaction was maintained for 48 hours at C temperature; the reaction product was washed with deionized water, acetone, and absolute ethanol, and collected by vacuum drying, and the resulting product was added to deionized water and NN-dimethylformaldehyde at a volume ratio of 1:1. In the mixed solution of methyl formamide, continuous ultrasonic oscillation for 12 hours, the solution was centrifuged at a speed of 600 revolutions per minute (r / min) for 30 minutes (min), the supernatant was taken, and the obtained supernatant was centrifuged at a speed of 6000 r / min The precipitate was collected for 10 min; then, the precipitate was washed with 3% HCl, deionized water, and absolute ethanol, dried in vacuum and the final product was collected. Scan...

Embodiment 2

[0018] In a high-pressure reactor with a volume of 50mL, add a certain amount of Li 2 CO 3 Powder, direct commercially purchased WS 2 Powder and 40mL organic solvent benzyl alcohol solution, put the autoclave at 200 o C for 24 hours of solvothermal reaction; the reaction product was washed with deionized water, acetone, and absolute ethanol, dried and collected in vacuum, and the resulting product was added to deionized water and NN-dimethylformaldehyde at a volume ratio of 1:1. In the mixed solution of methyl formamide, continuous ultrasonic oscillation for 12 hours, the solution was centrifuged at a speed of 600 revolutions per minute (r / min) for 30 minutes (min), the supernatant was taken, and the obtained supernatant was centrifuged at a speed of 6000 r / min The precipitate was collected for 10 min; then, the precipitate was washed with 3% HCl, deionized water, and absolute ethanol, dried in vacuum and the final product was collected.

Embodiment 3

[0020] In a high-pressure reactor with a volume of 50mL, add a certain amount of Li 2 CO 3 Powder, direct commercially purchased WS 2 Powder and 40mL organic solvent benzyl alcohol solution, put the autoclave at 200 o C for 72 hours of solvothermal reaction; the reaction product was washed with deionized water, acetone, and absolute ethanol, dried and collected under vacuum, and the resulting product was added to deionized water and NN-dimethyl In the formamide mixed solution, continuously ultrasonically oscillate for 12 hours, centrifuge the solution at a speed of 600 revolutions per minute (r / min) for 30 minutes (min), take the supernatant, and then centrifuge the obtained supernatant at a speed of 6000 r / min for 10 minutes The precipitate was collected; then, the precipitate was washed with 3% HCl, deionized water, and absolute ethanol, dried in vacuum and the final product was collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com