Spraying-absorbing-type method and spraying-absorbing-type device for waste heat recovery of fuel-gas flue gas

A technology of spray absorption and flue gas waste heat, applied in the field of energy, can solve the problems of not compact distribution of devices, increase of laying costs of smoke pipes and water pipes, pipe resistance, large area of device, etc., to achieve compact structure and shorten construction period , the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

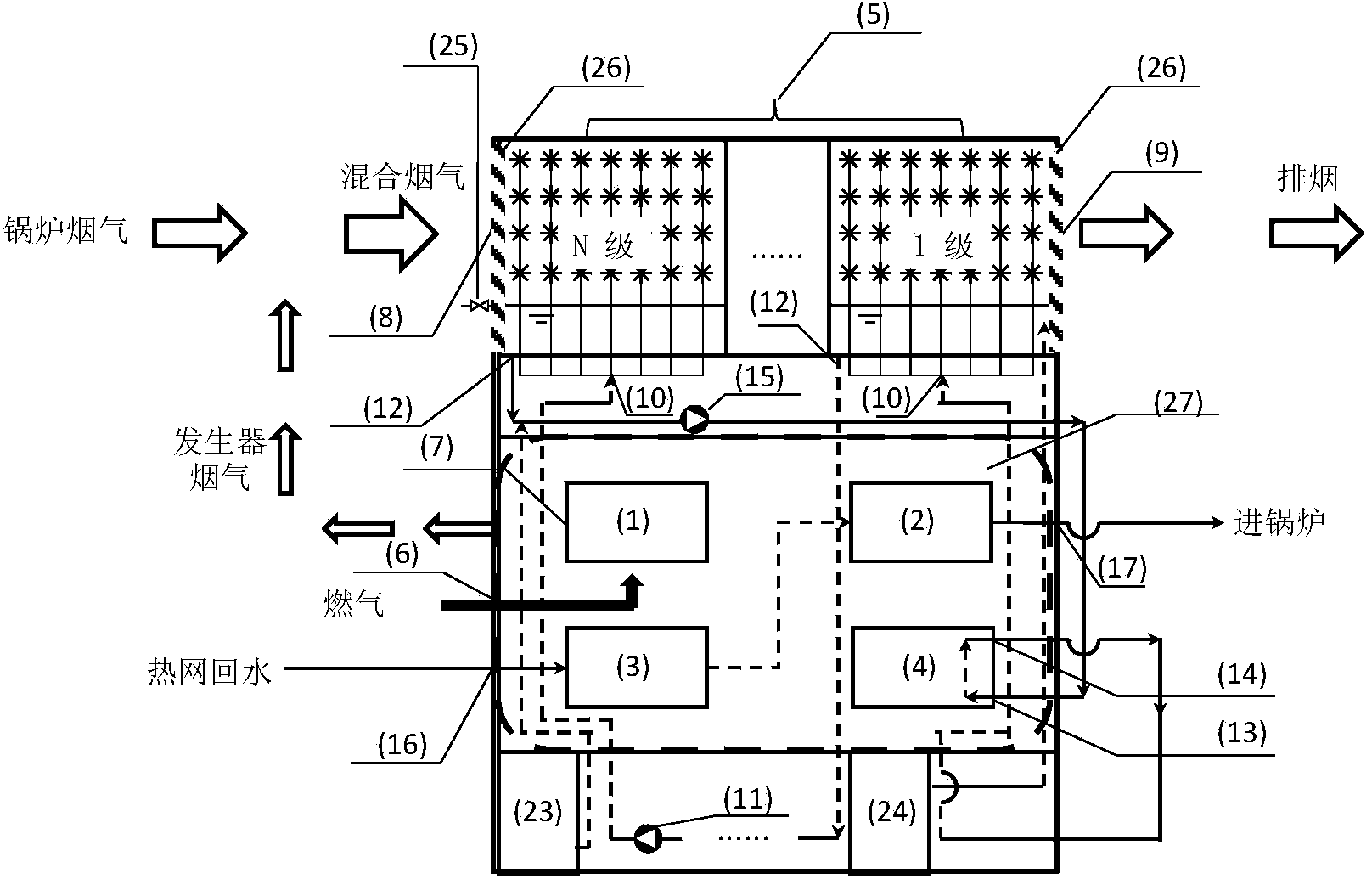

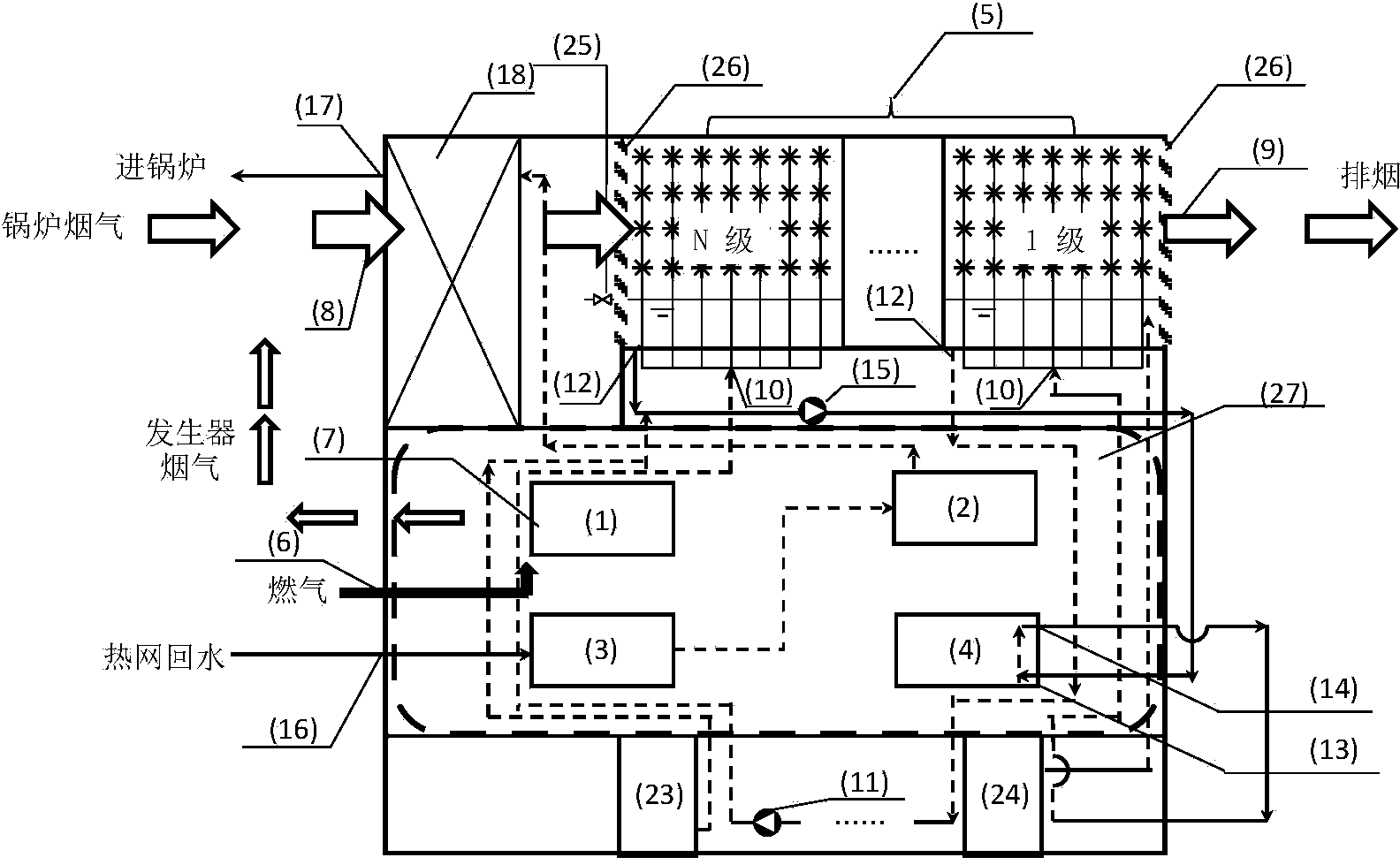

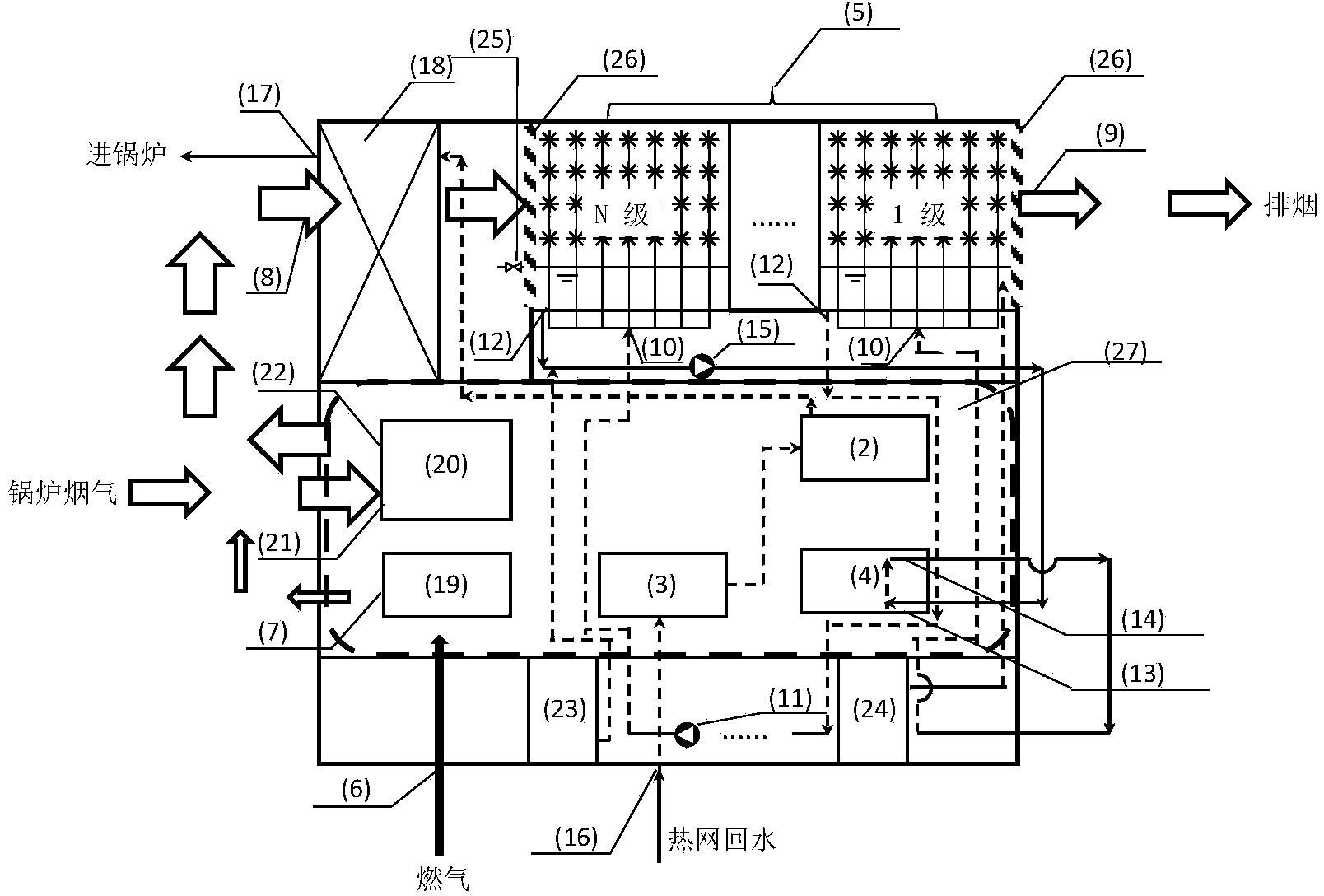

[0020] The present invention proposes a method and device for recovering waste heat from spray-absorbing gas flue gas, which will be described in detail below with reference to the accompanying drawings.

[0021] Such as figure 1As shown, the gas enters the gas-driven generator 1 from the gas inlet 6 and then provides the high-temperature heat source of the absorption refrigerator 27, and the exhausted flue gas is discharged from the flue gas outlet 7 of the gas-driven generator to recover the flue gas with the boiler flue gas in the waste heat The inlet 8 is mixed, and the mixed flue gas enters the n-stage spray unit 5, and is discharged from the unit through the exhaust outlet 9 after cooling down.

[0022] Among them, the self-circulating water enters the first-stage spraying unit from the circulating water inlet 10 of the spraying unit for spraying, and the outlet water of each spraying unit is transported to the next-stage spraying unit under the action of the spraying wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com