Pure magnesium or magnesium alloy surface thermal diffusion zincizing alloying method

A magnesium alloy and thermal diffusion technology, which is applied in the direction of solid-state diffusion coating, metal material coating process, coating, etc., can solve the problems of lower mechanical properties of the matrix, growth of the matrix structure, and high heating temperature, and achieve low equipment requirements. The effect of uniform and dense infiltrated layer structure and bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

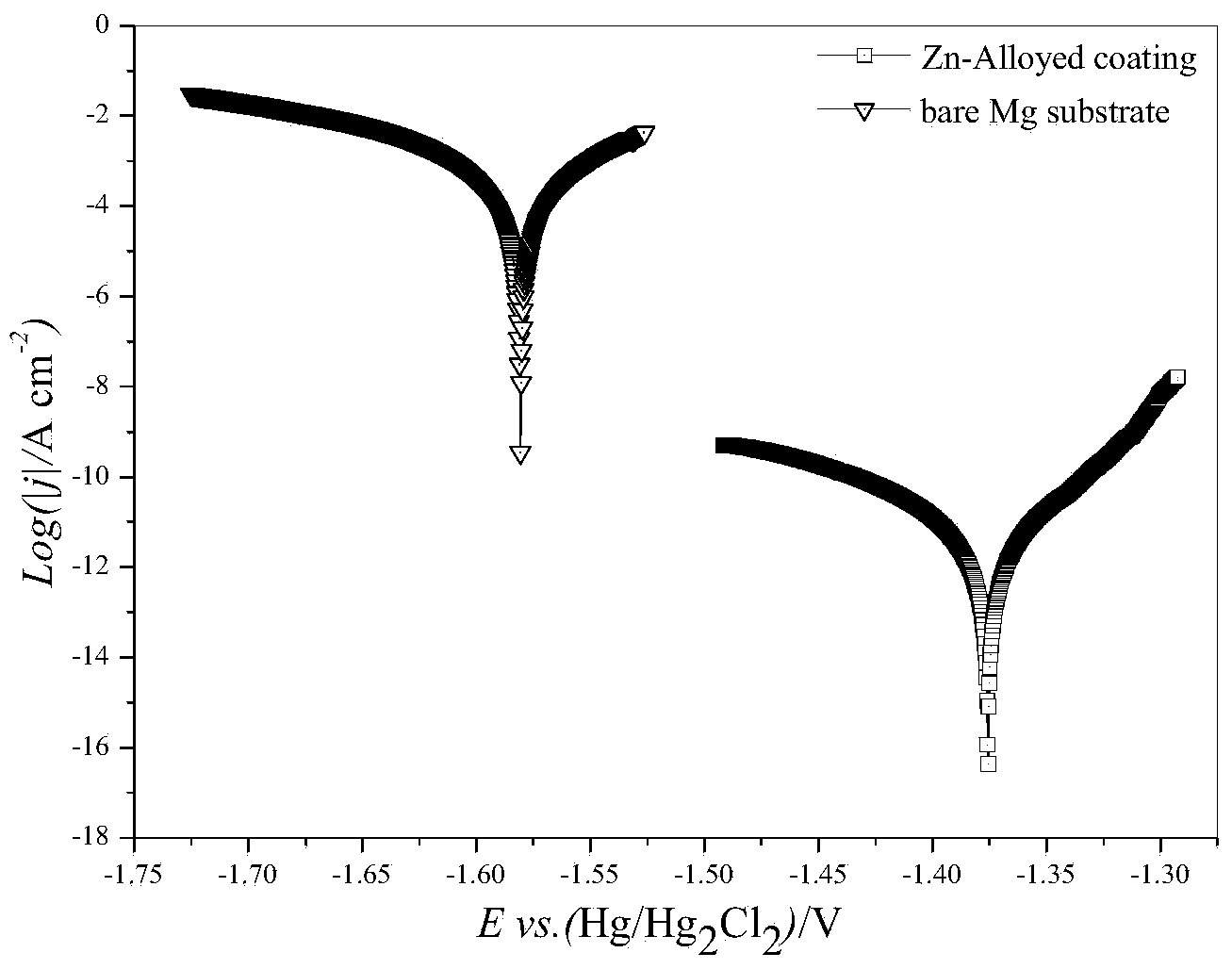

Image

Examples

Embodiment 1

[0027] Step 1, dry the pure zinc powder with a particle size of 25 μm to remove water vapor or other organic impurities in the zinc powder, and then put the pure zinc powder into the iron can;

[0028] Step 2, use 160#, 280#, 400#, 800#, 1200# metallographic sandpaper to grind or polish the pure magnesium workpiece in turn, remove the stains and plaques on the surface, make the surface smooth without obvious scratches, and then Wash in ultrasonic alcohol for 5 minutes to remove surface dirt, then wash in ultrasonic acetone for 5 minutes to remove surface organic matter, and finally wash with flowing deionized water and dry the workpiece with hot air;

[0029] Step 3, bury the pure magnesium workpiece after the surface treatment in step 2 in an iron can filled with pure zinc powder and shake it tightly to ensure that the workpiece is in close contact with the zinc powder;

[0030] Step 4, put the iron can together with the workpiece into the heating furnace for heating, the hea...

Embodiment 2

[0034] Step 1, drying the pure zinc powder with a particle size of 10 μm to remove water vapor or other organic impurities in the zinc powder, and then putting the pure zinc powder into the iron can;

[0035]Step 2, use 160#, 280#, 400#, 800#, 1200# metallographic sandpaper to grind or polish the magnesium alloy workpiece in turn, remove the stains and plaques on the surface, make the surface smooth without obvious scratches, and then Wash in ultrasonic alcohol for 3 minutes to remove surface dirt, then wash in ultrasonic acetone for 5 minutes to remove surface organic matter, and finally wash with flowing deionized water and dry the workpiece with hot air;

[0036] Step 3, embedding the magnesium alloy workpiece after the surface treatment in step 2 in an iron can filled with pure zinc powder and shaking it tightly to ensure that the workpiece is in close contact with the zinc powder;

[0037] Step 4, put the iron can together with the workpiece into the heating furnace for h...

Embodiment 3

[0039] Step 1, drying the pure zinc powder with a particle size of 100 μm to remove water vapor or other organic impurities in the zinc powder, and then putting the pure zinc powder into the iron can;

[0040] Step 2, use 160#, 280#, 400#, 800#, 1200# metallographic sandpaper to grind or polish the pure magnesium workpiece in turn, remove the stains and plaques on the surface, make the surface smooth without obvious scratches, and then Wash in ultrasonic alcohol for 8 minutes to remove surface dirt, then wash in ultrasonic acetone for 3 minutes to remove surface organic matter, and finally wash with flowing deionized water and dry the workpiece with hot air;

[0041] Step 3, bury the pure magnesium workpiece after the surface treatment in step 2 in an iron can filled with pure zinc powder and shake it tightly to ensure that the workpiece is in close contact with the zinc powder;

[0042] Step 4, put the iron can together with the workpiece into the heating furnace for heating,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com