Flame-retardant modified ammonium polyphosphate and preparation method and application thereof

An ammonium polyphosphate and modification technology, which is applied in the field of flame retardant modified ammonium polyphosphate and its preparation, can solve the problems of poor thermal stability and compatibility of substrates, complex synthesis process of carbon-forming agents, environmental and human injury, etc. , to achieve the effect of good flame retardant effect, easy industrial production, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

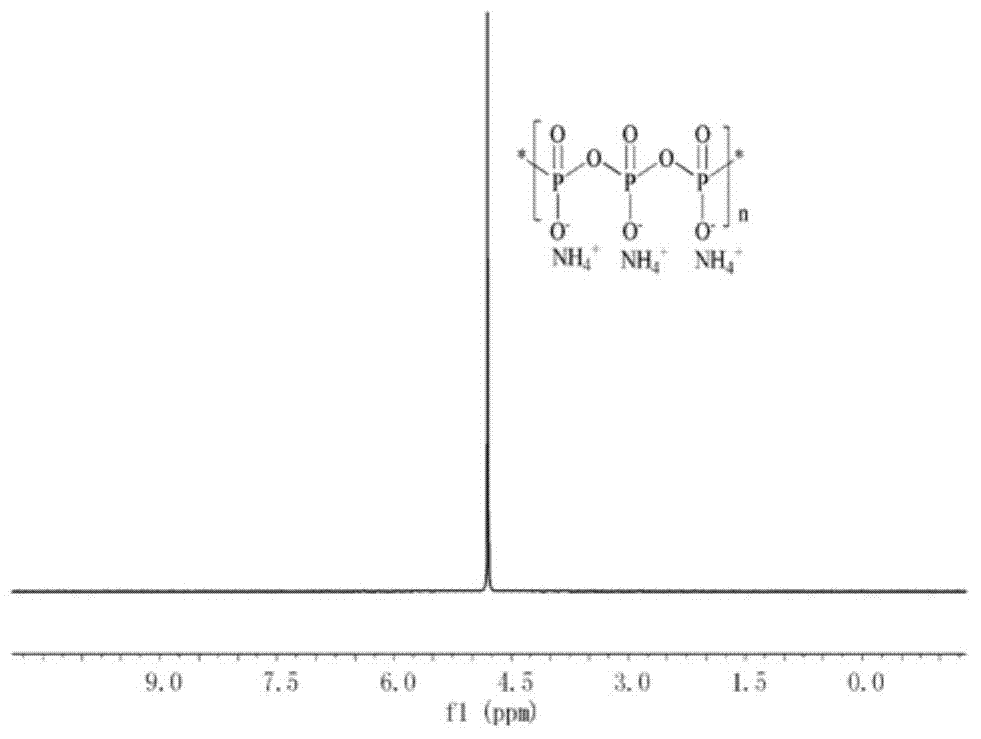

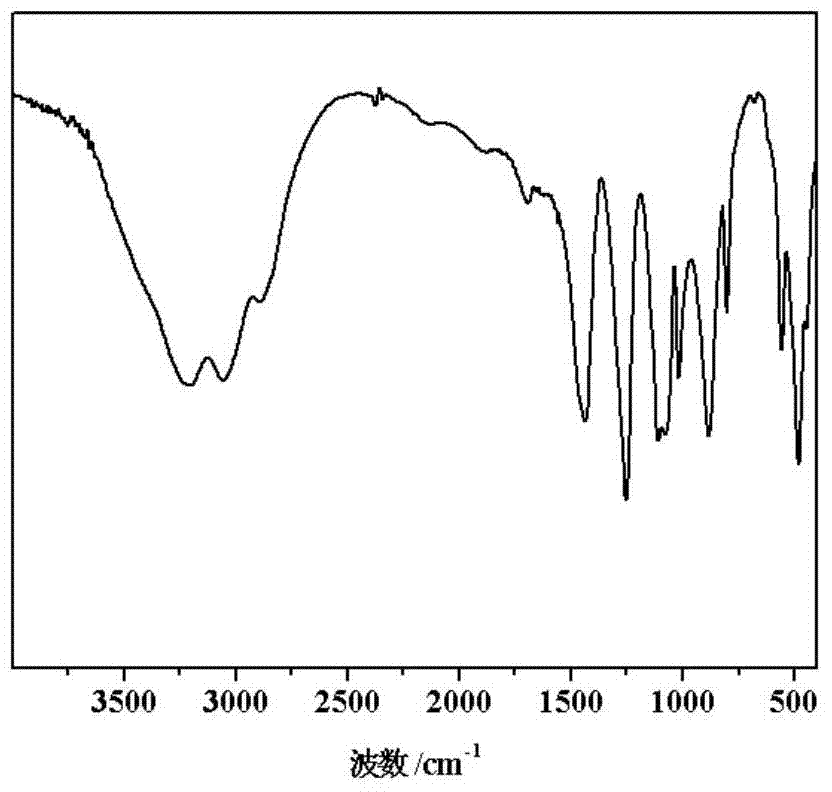

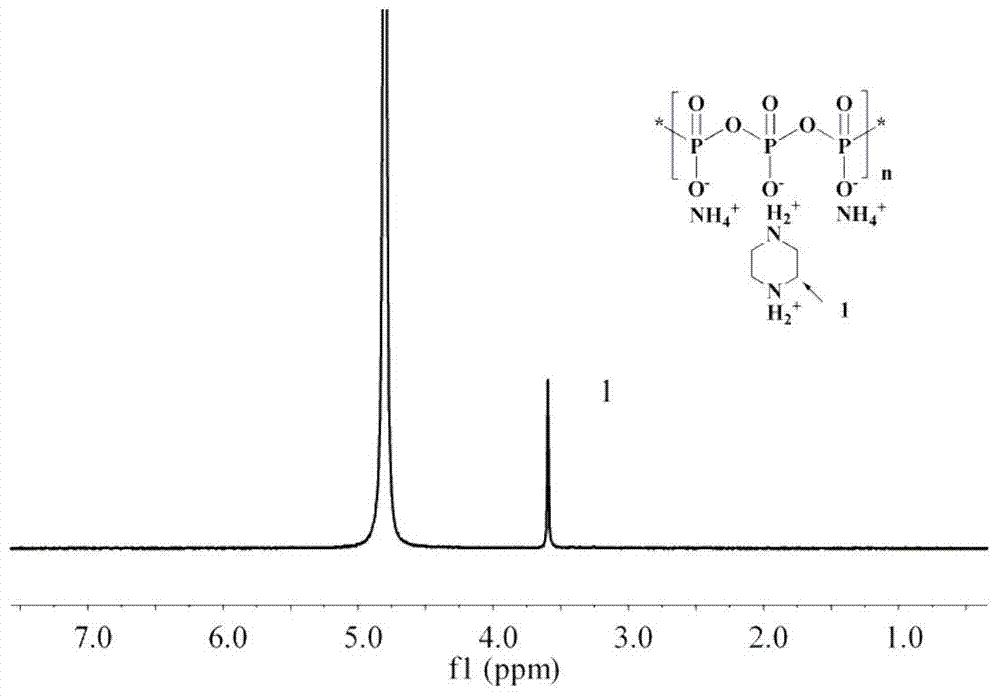

[0044] At room temperature, mix 600 parts of acetone and 6 parts of water as a solvent, add 8.6 parts of piperazine into it and stir to dissolve completely, then add 100 parts of ammonium polyphosphate II, then stir and heat up to 70°C under the protection of nitrogen, react for 2 hours, and filter , washed with acetone and dried to obtain the product with a yield of 90%.

Embodiment 2

[0046] At room temperature, mix 700 parts of methanol and 10.5 parts of water as a solvent, add 17.2 parts of piperazine into it and stir to dissolve completely, then add 100 parts of ammonium polyphosphate II, then stir and raise the temperature to 70°C under the protection of nitrogen, react for 2 hours, and filter , washed with methanol and dried to obtain the product with a yield of 89%.

Embodiment 3

[0048] At room temperature, mix 700 parts of ethanol and 14 parts of water as a solvent, add 51.6 parts of piperazine into it and stir to dissolve completely, then add 100 parts of ammonium polyphosphate II, then stir and raise the temperature to 80°C under the protection of nitrogen, react for 3 hours, and filter , washed with ethanol and dried to obtain the product with a yield of 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com