Purification and detection method for keratan sulfate in chondroitin sulfate

A technology of chondroitin sulfate and keratan sulfate, which is applied in the field of medicine, can solve the problems of difficult complete degradation, expensive enzymes, and long time consumption, and achieve the effects of short detection time, small sample consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

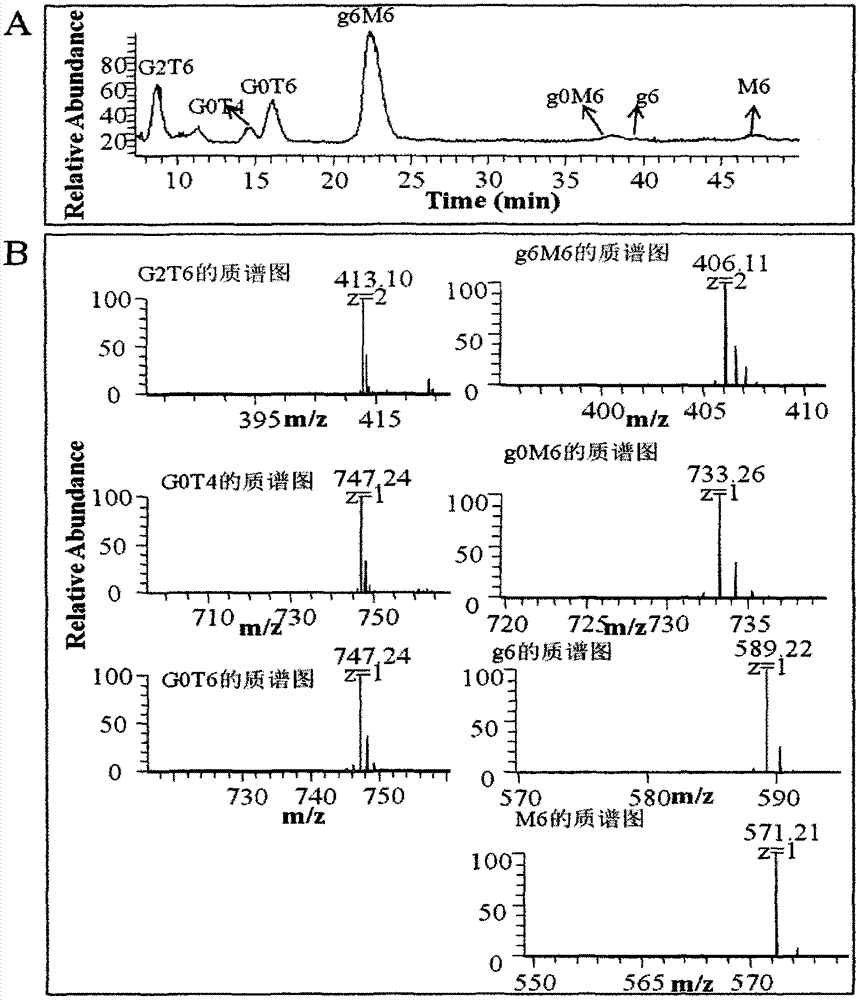

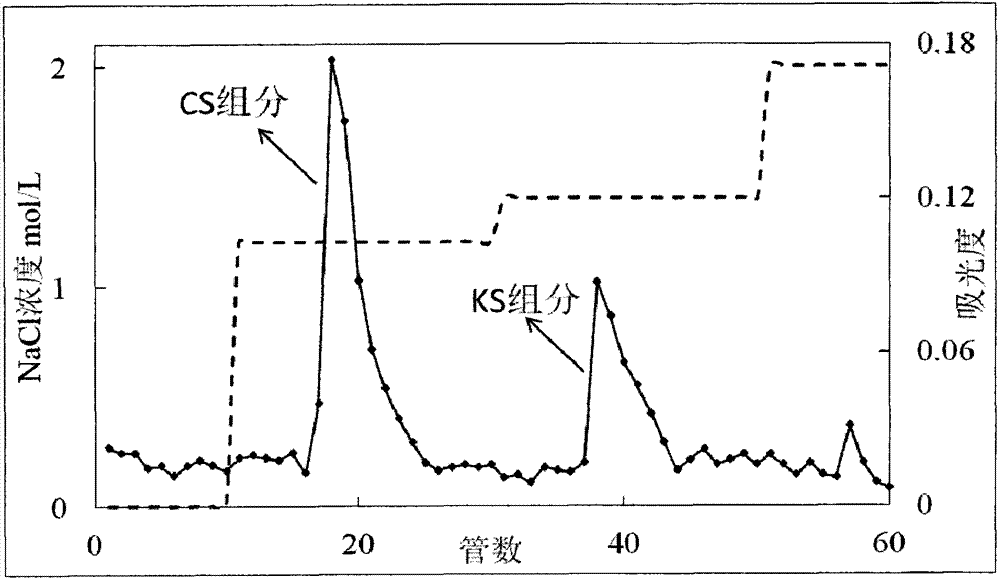

[0045] The chemical degradation of example 1 chondroitin sulfate mixture

[0046] (1) Dissolve 0.5 mg of chondroitin sulfate mixture in 0.25 mL containing 10% N 2 h 4 ·H 2 SO 4 N 2 h 4 ·H 2 O solution, heated to dissolve, then sealed and heated to 98 ° C, reacted for 7 hours, after the reaction was completed, freeze-dried to remove N 2 h 4 Deacetylated products are obtained;

[0047] (2) Completely dissolve the deacetylated product obtained in step (1) in 50uL water, add 50uL sodium nitrite aqueous solution with a pH of 1.5, adjust the pH to 4.0 after reacting at 0-5°C for 10 minutes, and add 50uL sodium nitrite with a pH of 4.0 Nitric acid, continue to react at 0-5°C for 10 minutes, and add 30uL ammonia water to terminate the reaction.

example 2

[0048] The chemical degradation of example 2 chondroitin sulfate mixture

[0049] (1) Dissolve 0.5 mg of chondroitin sulfate mixture in 0.5 mL containing 10% N 2 h 4 ·H 2 SO 4 N 2 h 4 ·H 2 O solution, heated to dissolve, then sealed and heated to 80 ° C, reacted for 4 hours, after the reaction was completed, freeze-dried to remove N 2 h 4 Deacetylated products are obtained;

[0050] (2) Completely dissolve the deacetylated product obtained in step (1) in 50uL water, add 50uL sodium nitrite aqueous solution with a pH of 1.5, adjust the pH to 4.0 after reacting at 0-5°C for 10 minutes, and add 50uL sodium nitrite with a pH of 4.0 Nitric acid, continue to react at 0-5°C for 10 minutes, and add 30uL ammonia water to terminate the reaction.

example 3

[0051] The chemical degradation of example 3 chondroitin sulfate mixture

[0052] (1) Dissolve 0.5 mg of chondroitin sulfate mixture in 0.5 mL containing 10% N 2 h 4 ·H 2 SO 4 N 2 h 4 ·H 2 O solution, heated to dissolve, then sealed and heated to 105 ° C, reacted for 16 hours, after the reaction was completed, freeze-dried to remove N 2 h 4 Deacetylated products are obtained;

[0053] (2) Completely dissolve the deacetylated product obtained in step (1) in 50uL of water, add 50uL of sodium nitrite aqueous solution with a pH of 1.5, adjust the pH to 4.0 after reacting at 5°C for 10 minutes, and add 50uL of nitrous acid with a pH of 4.0 , continue to react at 5°C for 10 min, and add 30 uL of ammonia water to terminate the reaction.

[0054] The chemical degradation products of the chondroitin sulfate mixture in Examples 2-4 were detected, and the results are shown in Table 2.

[0055] Table 2 Analysis of chemical degradation products of chondroitin sulfate mixture

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com