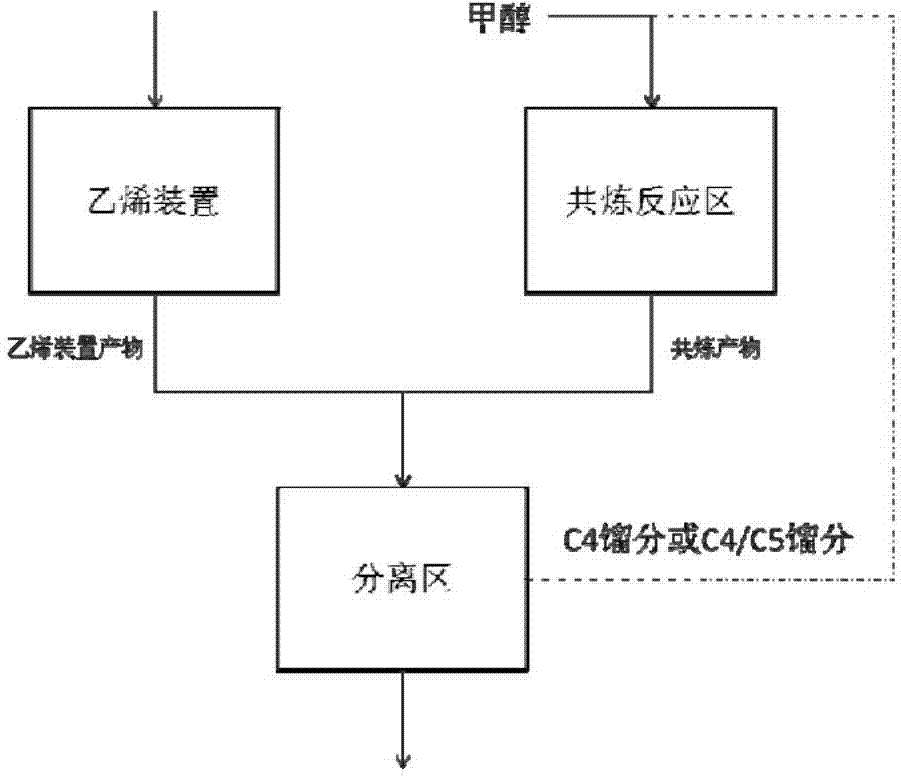

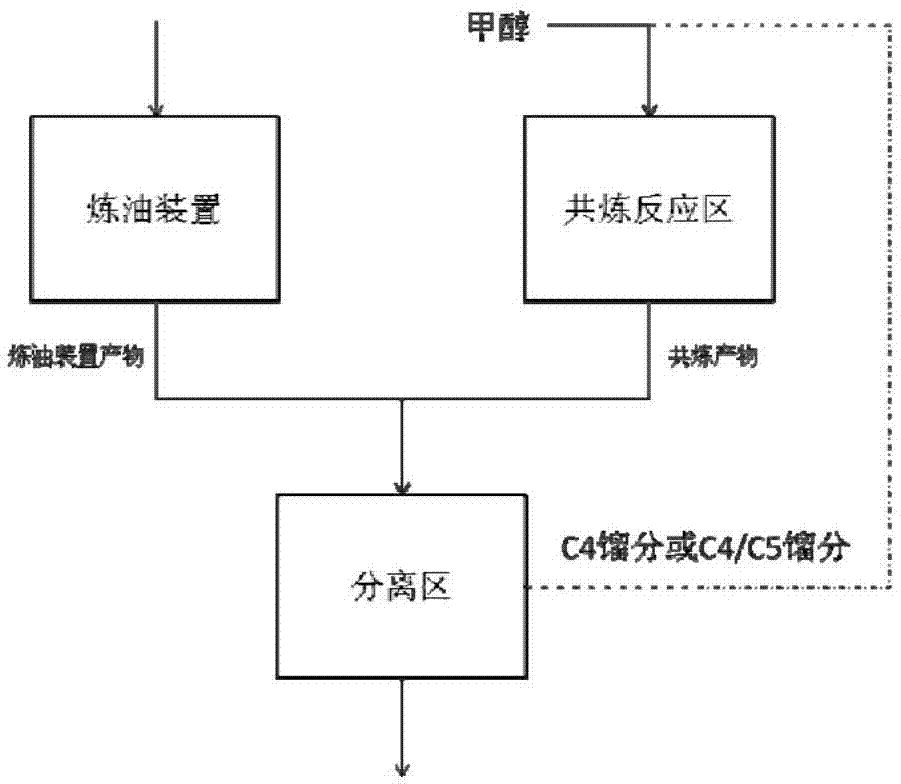

Process for producing propylene by using alcohol-hydrocarbon co-refining technology

A technology of co-refining and propylene, applied in ethylene production, biological raw materials, hydrocarbon cracking to produce hydrocarbons, etc., can solve problems such as affecting product distribution, affecting the stability of reactor temperature, etc., to reduce the difficulty of heat exchange, improve added value, The effect of promoting generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Choose phosphorus-modified ZSM-5 as a catalyst, and the preparation method is as follows:

[0035]The required raw materials are HZSM-5 molecular sieve (Si:Al=50) and phosphoric acid aqueous solution, and the ZSM-5 molecular sieve catalyst containing 2% phosphorus is obtained by spray drying, and additives can be added as appropriate during the preparation process. The above-mentioned raw materials and additives can be obtained by purchasing commercial products, and the HZSM-5 molecular sieve can also be prepared according to the method disclosed in the literature (Molecular Sieve and Porous Material Chemistry, Xu Ruren, Science Press).

[0036] The co-refining reaction zone is composed of two fluidized beds connected in series. The temperature inside the first reactor is 530°C, the pressure is 0.18Mpa, and the mass space velocity is 3h -1 ; The temperature in the second reactor is 470℃, the pressure is 0.16MPa, and the mass space velocity is 1h -1 . C 4 The distill...

Embodiment 2

[0039] Phosphorus-magnesium modified ZSM-5 is a catalyst, and the preparation method is as follows:

[0040] The required raw materials are HZSM-5 molecular sieve (Si:Al=50), binder, phosphoric acid, magnesium nitrate aqueous solution, mix HZSM-5 molecular sieve and binder at a ratio of 3:1, and obtain strips by extrusion molding method Shaped HZSM-5 molecular sieve, and the ZSM-5 catalyst containing 1% phosphorus and 2% magnesium was obtained by impregnation method, and additives can be added as appropriate during the preparation process.

[0041] The co-refining reaction zone is composed of two parallel fixed beds. The temperature in both reactors is 500°C, the pressure is 0.18Mpa, and the mass space velocity is 1.5h -1 . C 4 The distillates are mixed with methanol and water vapor in a mass ratio of 1:1:4 and then injected from the inlets of the two reactors respectively. The mass ratio of methanol injected from the inlet to the middle is 2:1. All the rest are carried o...

Embodiment 3

[0044] Select high-silicon HZSM-5 (Si:Al=200) as the catalyst, and the preparation method is as follows:

[0045] The required raw material is high-silicon HZSM-5 molecular sieve (Si:Al=200), and the spherical high-silicon HZSM-5 molecular sieve catalyst is obtained by rotational molding method, and additives can be added as appropriate during the preparation process. The above-mentioned raw materials and additives can be obtained by purchasing commercial products, and the HZSM-5 molecular sieve can also be prepared according to the method disclosed in the literature (Molecular Sieve and Porous Material Chemistry, Xu Ruren, Science Press).

[0046] A moving bed constitutes a co-refining reaction zone. The temperature in the reactor is 490°C, the pressure is 0.18Mpa, and the mass space velocity is 1h -1 . C 4 The distillate is mixed with methanol and steam at a mass ratio of 3:5:10 for heat exchange and then injected from the inlet of the reactor. All the rest are carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com