Temperature control method based on variable region dynamic temperature acquisition and data fusion

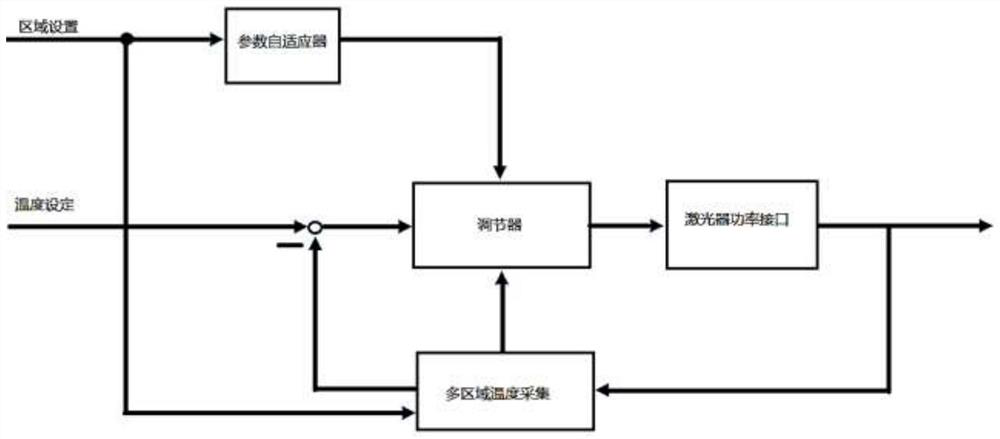

A temperature control method and dynamic temperature technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of high temperature control cost, inaccurate and comprehensive control, and inability to realize local area control on a two-dimensional plane in space. temperature and other problems, to achieve the effect of improving the accuracy of temperature control and reducing the difficulty of temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] S1. Reflect the infrared radiation on the surface of the object to the temperature measuring head of the infrared temperature sensor through the infrared reflector that can rotate at high speed. The infrared reflector rotates at a high speed along the set movement path to measure the temperature of different points on the object surface in real time; The number of mirrors is two, the response time of the infrared temperature sensor is 1 ms, the temperature range is 100 degrees Celsius to 600 degrees Celsius, and the detection diameter is 2 mm. The number of infrared temperature measuring sensor and laser integrated temperature control device is one, and the infrared reflector is driven to rotate by a servo motor. The infrared radiation on the surface of the object is reflected to the temperature control device through two infrared reflectors in turn.

[0029] S2. Group the regions according to the minimum unit area, and realize data fusion by calculating the average tem...

Embodiment 2

[0033] S1. Reflect the infrared radiation on the surface of the object to the temperature measuring head of the infrared temperature sensor through the infrared reflector that can rotate at high speed. The infrared reflector rotates at a high speed along the set movement path to measure the temperature of different points on the object surface in real time; The number of mirrors is one, the number of temperature control devices is several, and the infrared radiation on the surface of the object is reflected to several temperature control devices through an infrared reflector;

[0034] S2. Group the regions according to the minimum unit area, and calculate the average temperature on the unit area according to the Gaussian distribution to realize data fusion.

[0035] S3. Using the sliding mode variable structure control method to optimize and adjust the parameter model according to the regional dynamics; since the sliding mode of the sliding mode variable structure control can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com