Quasi monocrystalline silicon casting device and method

A technology of quasi-single crystal silicon and ingot casting equipment, which is applied in the field of quasi-single crystal silicon ingot casting and ingot casting, can solve the problems affecting the efficiency of quasi-single crystal silicon ingot casting, the difficulty of temperature gradient control, and the difficulty of improving the process, etc., to achieve Low cost, wide range of applications, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

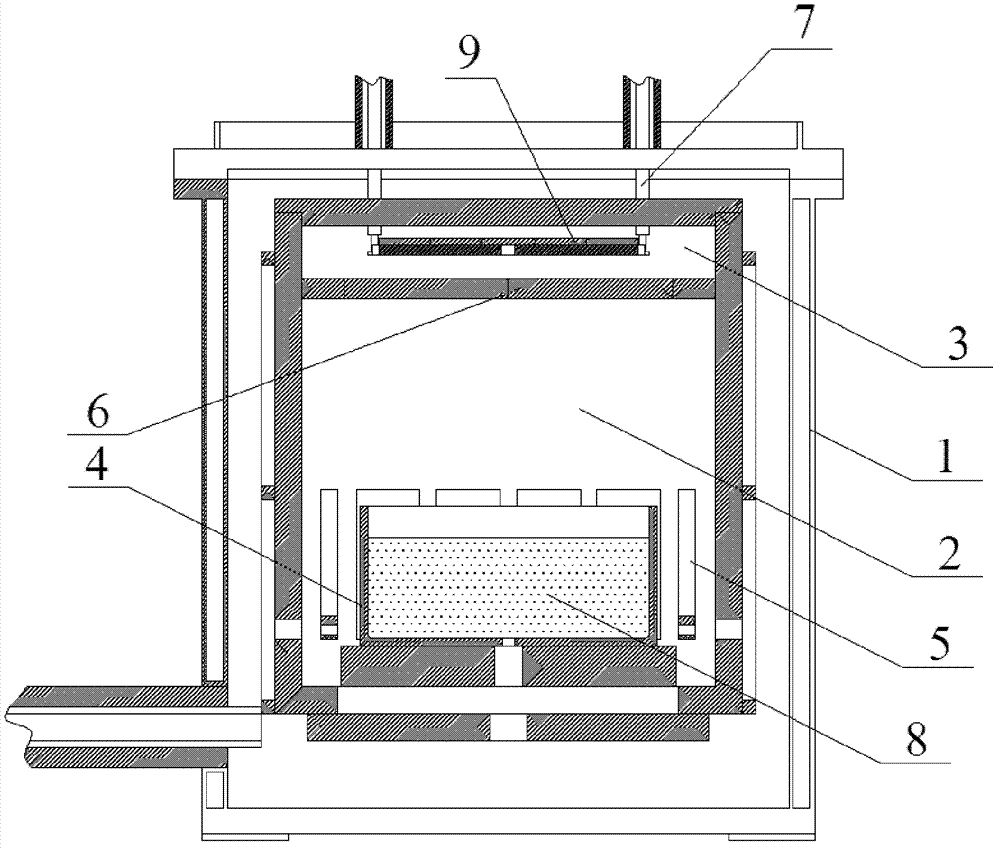

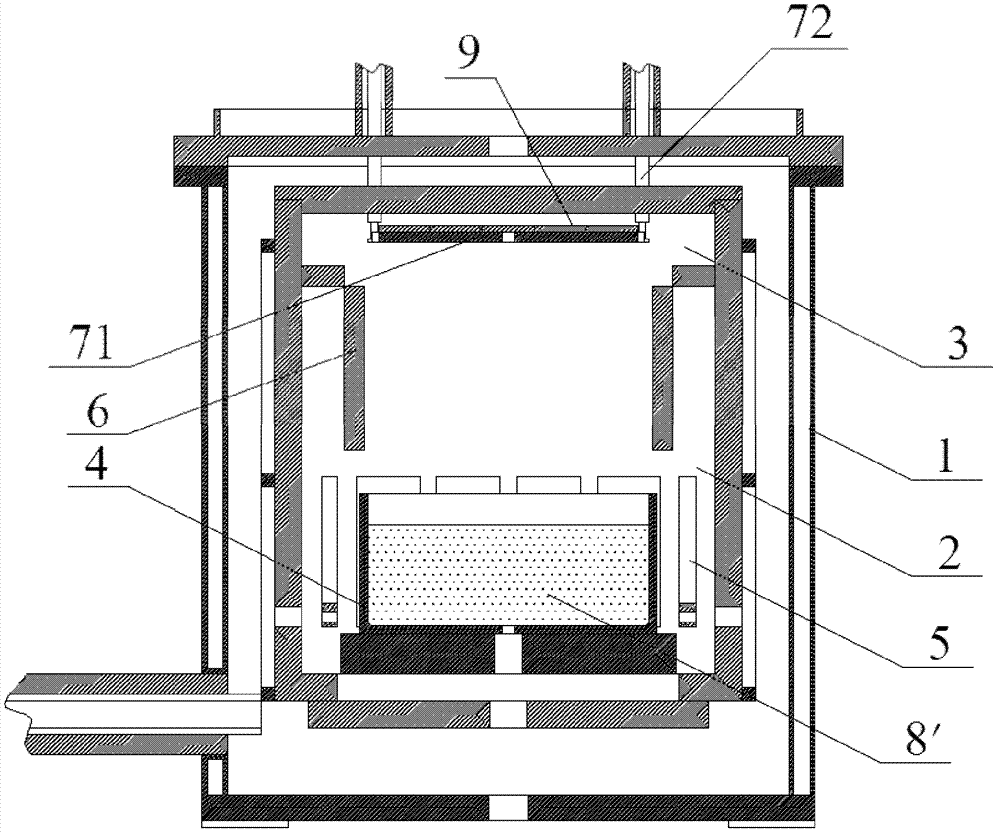

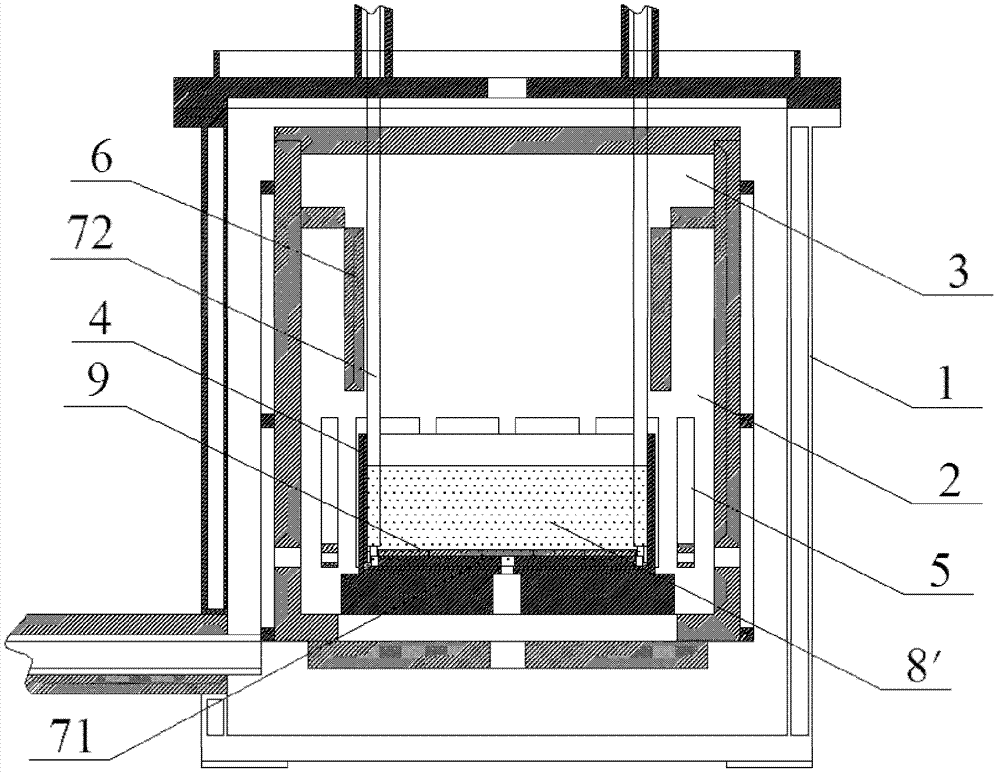

[0060] see figure 1 Shown is a schematic structural view of an embodiment of the quasi-single crystal silicon ingot casting equipment of the present invention.

[0061] The quasi-single crystal silicon ingot casting equipment includes a housing 1, an ingot chamber 2 and a seed crystal storage chamber 3 arranged in the housing 1, a crucible 4 and a heating device arranged in the ingot chamber 2 5. An insulated door 6 arranged between the seed crystal storage chamber 3 and the ingot casting chamber 2, and used to pass the seed crystal through the insulated door 6 and set it in the seed crystal storage chamber 3 or the seed crystal feeding device 7 in the crucible 4 of the ingot chamber 2. Wherein, the heating device 5 is arranged around the crucible 4, and the surface of the crucible 4 can have silicon nitride (SiN) with a thickness less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com