A transition layer surface modification method capable of regulating interfacial nanoparticles

A nanoparticle and surface modification technology, applied in the field of high-temperature superconducting material preparation, can solve the problems of difficulty in controlling particle dispersion, size and particle density, limited effect, and difficulty in pinning the number of defects, preventing particle agglomeration, Good particle shape, avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Cut and polish the (001)-LAO single crystal substrate away from (001) by 10°.

[0025] 2) Dissolve zirconium acetylacetonate and yttrium acetylacetonate in n-propionic acid at a molar ratio of zirconium ions to cerium ions of 0.9:0.1 and a total concentration of zirconium ions and yttrium ions of 0.001mol / L to obtain a precursor solution;

[0026] 3) Apply the precursor solution in step 2) to the single crystal substrate treated in step 1) by spin coating, the rotation speed is 1000rpm, and the time is 100s to obtain the precursor film;

[0027] 4) in H 2 Mixing with Ar (H 2 The volume percentages of Ar and Ar were 4% and 96%, respectively) under gas protection conditions, the precursor film was sintered at 1300 °C for 200 minutes to obtain YSZ nanodots.

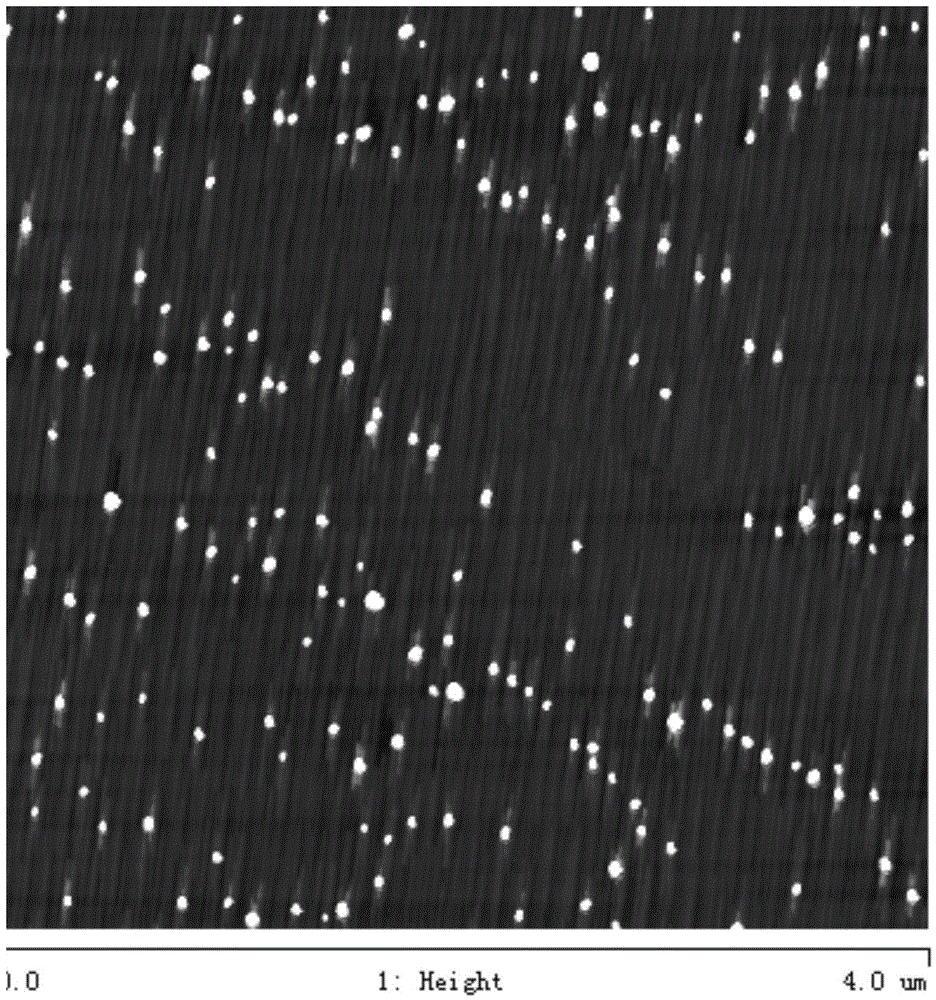

[0028] 5) The surface topography of YSZ is as follows figure 1 As shown, the AFM-3D photos show that the nanodots are completely dispersed by the step flow, and the particle size is the same as the width of the ...

Embodiment 2

[0030] 1) Cut and polish the (001)-LAO single crystal substrate away from (001) by 20°.

[0031] 2) Dissolve zirconium acetylacetonate and cerium acetylacetonate in n-propionic acid, according to the molar ratio of zirconium ions and cerium ions of 0.8:0.2, and the total concentration of zirconium ions and cerium ions at 0.003 mol / L, to obtain a precursor solution;

[0032] 3) Apply the precursor liquid obtained in step 2) to the single crystal substrate processed in step 1) by spin coating, the rotation speed is 5000rpm, and the time is 40s to obtain the precursor film;

[0033] 4) in H 2 Mixing with Ar (H 2 The volume percentages of Ar and Ar are 4% and 96%, respectively) under gas protection conditions, the precursor film obtained in step 3) was sintered at 1150°C for 300 minutes to obtain CZO nanodots.

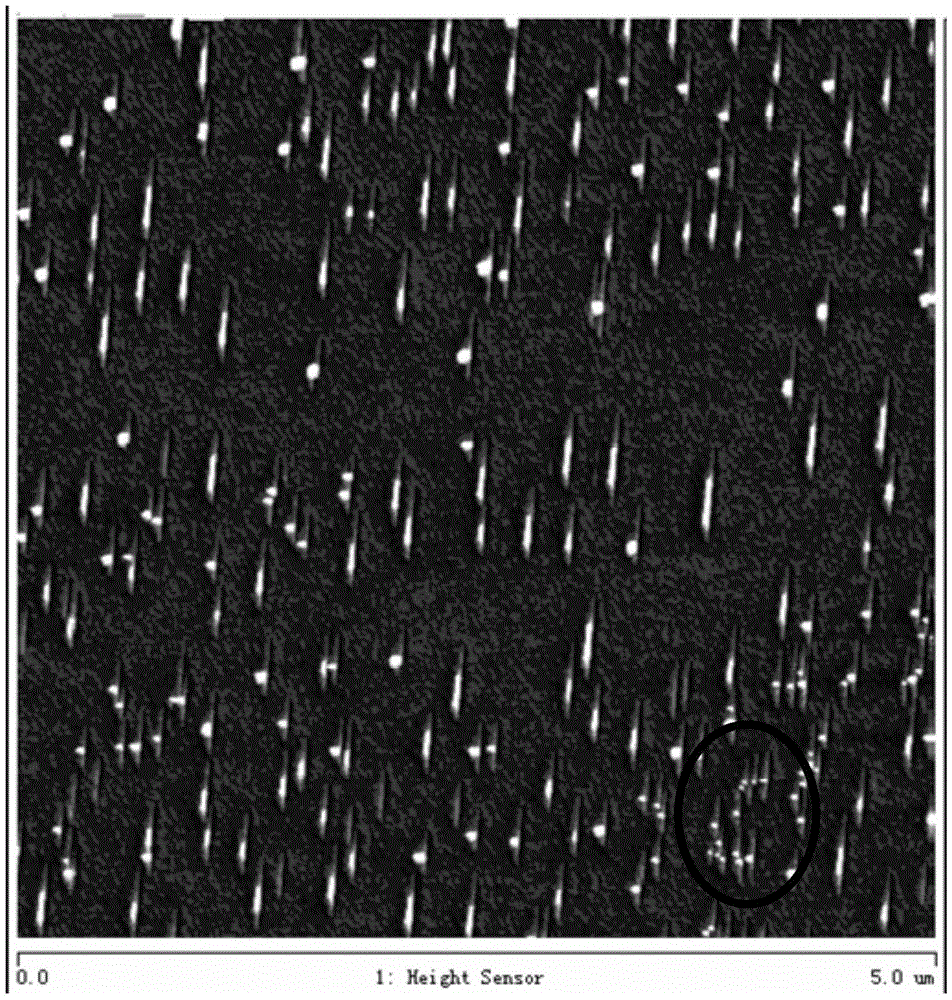

[0034] 5) The three-dimensional surface morphology of CZO as figure 2 It can be seen from the AFM-3D diagram that the number of prepared nanoparticles is affected by t...

Embodiment 3

[0036] 1) Prepare scratches on the LAO single crystal substrate with a nanoindenter, where the indentation force is 0.6mN and the interval is 500nm;

[0037] 2) Dissolve lanthanum acetylacetonate into n-propionic acid to obtain a precursor solution with a concentration of 0.03mol / L;

[0038] 3) Apply the precursor solution obtained in step 2) to the single crystal substrate processed in step 1) by spin coating, the rotation speed is 6000rpm, and the time is 200s to obtain the precursor film;

[0039] 4) Under the protection of Ar gas, the precursor film obtained in step 3) was sintered at 1300°C for 200 minutes to obtain La 2 o 3 nano dots.

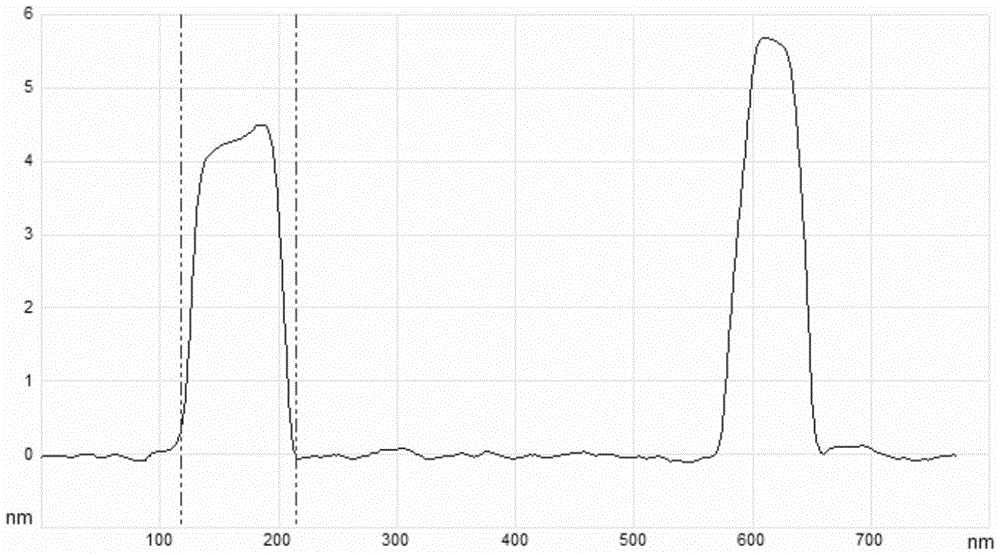

[0040] 5) La 2 o 3 The line scan diagram is as follows image 3 As shown, the nanoparticles are about 5 nm high and spaced about 500 nm apart, which is comparable to the pitch of the indentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com