Grafted copolymer, grafted copolymer/silver nanocomposite and preparation method thereof

A technology of graft copolymer and composite material, applied in the field of graft copolymer/silver nanocomposite material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] (1) Synthesis of polyvinyl acetate

[0083] Using 100 mL of vinyl acetate (VAc) as raw material, 0.146 g of azobisisobutyronitrile as an initiator, and methanol as a solvent, a free radical polymerization reaction was carried out at a reaction temperature of 70° C. and a reaction time of 3 h. After the reaction, the solvent and unpolymerized monomers in the product were distilled off under reduced pressure to obtain polyvinyl acetate; the product polyvinyl acetate was vacuum-dried to constant weight at 40°C for subsequent use;

[0084] (2) Preparation of polyvinyl acetate of partial alcoholysis

[0085] 4g of polyvinyl acetate was completely dissolved in methanol / water (9:1, v / v) mixed solution, and hydrochloric acid was added to adjust [H + ] Concentration is 0.2mol / L, reaction time is 2h, obtains the polyvinyl acetate (PVAc-OH) of partial alcoholysis that alcoholysis degree is 9.43%, the PVAc-OH is vacuum-dried to constant weight at 40 ℃;

[0086] (3) Preparation of...

Embodiment 2

[0098] The preparation method is as in Example 1, except that in step (5), 0.26 g of polyisobutylene containing allyl bromide as a macroinitiator is used as the macroinitiator, and the amount of silver perchlorate is 0.015 g. The grafting efficiency was 100%.

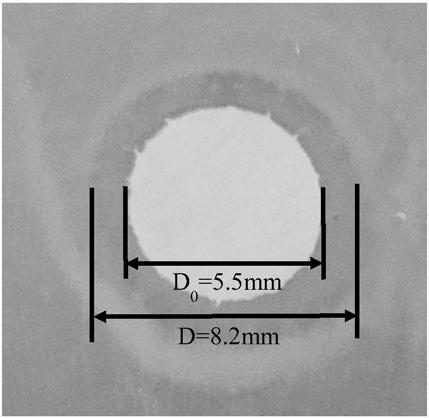

[0099] The absolute weight-average molecular weight of polyvinyl alcohol and polyisobutylene graft copolymer is 160kg / mol, the mass percent content of PIB branched chain is 61%, the graft density is 1.6%, the contact angle is 48 °, and the Ag content is 0.98%, The molecular weight of the main chain is 29kg / mol, the molecular weight of the branched chain is 4500g / mol, the number of THF linking units is 2, D is 6.5mm, R is 1.18, no cytotoxicity, and the cell survival rate is 100%.

Embodiment 3

[0101] The preparation method is the same as in Example 1, except that in step (5), 0.52 g of polyisobutylene whose end group contains allyl bromide is used as a macroinitiator, and the amount of silver perchlorate is 0.03 g. The grafting efficiency was 99%.

[0102] The absolute weight-average molecular weight of polyvinyl alcohol and polyisobutylene graft copolymer is 235kg / mol, the mass percent content of PIB branched chain is 76%, the graft density is 3.1%, the contact angle is 73°, and the Ag content is 1.91%. The molecular weight of the main chain is 29kg / mol, the molecular weight of the branched chain is 4500g / mol, the number of THF linking units is 2, D is 8.0mm, R is 1.45, the cell survival rate is 82%, and the cytotoxicity is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absolute weight average molecular weight | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Absolute weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com