A kind of crystallization tower equipment of lower melting point substance

A technology of crystallization equipment and crystallization tower, which is applied in the direction of solution crystallization, can solve the problems of crystal discharge, large amount of solvent, limited heat exchange area, etc., and achieve the effects of increasing fluidity, increasing content, and reducing solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

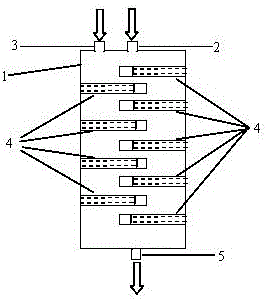

[0024] Embodiment 1: the refining of 2-chloro-5-chloromethylthiazole

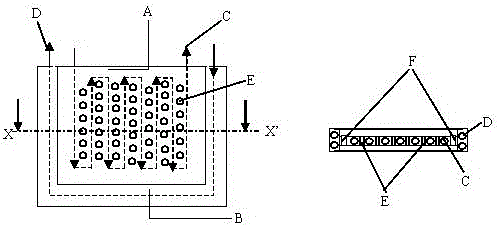

[0025] Gradient temperature control of the crystallization tray of the equipment: the temperature of the convex part B of the crystallization tray is controlled at 28-30 °C, and the temperature of the concave part A of the tray is controlled at 3-5 °C.

[0026] Add 20kg of dichloromethane to 180kg of 2-chloro-5-chloromethylthiazole (content 90-94%), control the temperature at 35°C, and enter the crystallization from the mother liquor feed port 2 through the material distributor at a flow rate of 50kg / h In the tower body 1, after adding the materials; the crystallization tray 4 starts to heat up slowly to 20-23°C, and maintains it for a certain period of time, so that the molten material drops; the nitrogen gas with a certain flow rate is introduced from the nitrogen inlet 3, and then the crystallization tray 4 The temperature is raised to 28°C and kept for a period of time. The material adhering to the c...

Embodiment 2

[0027] The refining of embodiment 2 chlorpyrifos

[0028] Gradient temperature control of the crystallization tray of the equipment: the temperature of the convex part of the crystallization tray is controlled at 41-43°C, and the temperature of the concave part of the tray is controlled at 0-5°C.

[0029] Add 20kg of dichloroethane to 150kg of chlorpyrifos (90-95%), control the temperature at 48-50°C, enter the crystallization tower body 1 from the mother liquor feed port 2 through the material distributor at a flow rate of 50kg / h, add After the material is finished; the crystallization tray 4 begins to heat up slowly to 36-38°C, and keeps it for a certain period of time, so that the molten material drops; the nitrogen gas with a certain flow rate is introduced from the nitrogen inlet 3, and kept for a period of time, the material adhering to the crystal surface It is blown off by nitrogen and enters the solvent recovery tank. Because chlorpyrifos has a mercaptan odor, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com