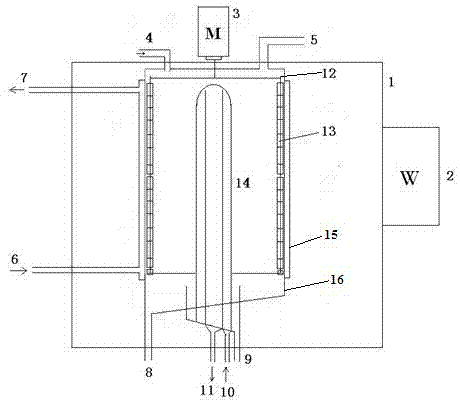

Microwave wiped film type molecular distiller with thin film evaporator function and method for generating fatty acid methyl ester by distiller

A thin-film evaporator and fatty acid methyl ester technology, which is applied in molecular distillation, fatty acid esterification, separation methods, etc., can solve the problems of complex product purification, environmental secondary pollution, and impact on fatty acid methyl ester, etc., to reduce production process costs , saving energy and time, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 400 g of methanol and 2.0 g of sodium hydroxide catalyst to 100 g of rapeseed oil to form a solution, turn on the heating, gradually raise the temperature to 60°C, and alcoholyze for 8 hours to obtain a fatty acid methyl ester mixture;

[0046] The fatty acid methyl ester mixture is separated by a microwave wiped-film molecular still with the function of a thin-film evaporator:

[0047] (1) Turn on the switch of the cold wall condensate circulator and set the temperature required for the experiment to 40°C;

[0048] (2) Turn on the hot wall heating power supply and cycle switch, and set it to the temperature required for the experiment at 120°C;

[0049] (3) Connect the vacuum outlet of the equipment to the cold trap and vacuum pump. After the temperature of the heating cycle in the jacket of the still is stable, turn on the vacuum pump to make the system pressure reach the set vacuum degree of 0.01KPa.

[0050] (4) The fatty acid methyl ester mixed solution is ad...

Embodiment 2

[0058] Add 600 g of methanol and 3.5 g of sodium hydroxide catalyst to 100 g of soybean oil to form a solution, turn on the heating, gradually raise the temperature to 100°C, and alcoholyze for 4 hours to obtain a fatty acid methyl ester mixture;

[0059] The fatty acid methyl ester mixture is separated by a microwave wiped-film molecular still with the function of a thin-film evaporator:

[0060] (1) Turn on the switch of the cold wall condensate circulator and set the temperature required for the experiment to 40°C;

[0061] (2) Turn on the hot wall heating power supply and cycle switch, and set it to the required temperature of 180°C for the experiment;

[0062] (3) Connect the vacuum outlet of the equipment to the cold trap and vacuum pump. After the temperature of the heating cycle in the jacket of the still is stable, turn on the vacuum pump to make the system pressure reach the set vacuum degree of 10KPa.

[0063] (4) The fatty acid methyl ester mixed solution is adde...

Embodiment 3

[0071] Add 500g methanol and 3.0g sodium hydroxide catalyst to 100g peanut oil to form a solution, gradually heat to 90°C, and alcoholyze for 5 hours to obtain a fatty acid methyl ester mixture;

[0072] The fatty acid methyl ester mixture is separated by a microwave wiped-film molecular still with the function of a thin-film evaporator:

[0073] (1) Turn on the switch of the cold wall condensate circulator and set the temperature required for the experiment to 45°C;

[0074] (2) Turn on the hot wall heating power supply and cycle switch, and set it to the temperature required for the experiment at 160°C;

[0075] (3) Connect the vacuum outlet of the equipment to the cold trap and vacuum pump. After the temperature of the heating cycle in the jacket of the still is stable, turn on the vacuum pump to make the system pressure reach the set vacuum degree of 1.0KPa.

[0076] (4) The fatty acid methyl ester mixture is added to the feeder, and the feeder insulation device is turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com