Redrying and mellowing method for reducing crotonaldehyde release amount

A technology of release amount and crotonaldehyde, applied in the treatment of tobacco, tobacco, application, etc., can solve the problems of reducing the release amount of crotonaldehyde, reducing the release amount of crotonaldehyde in cigarette smoke, etc., and achieve the effect of improving degradation and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

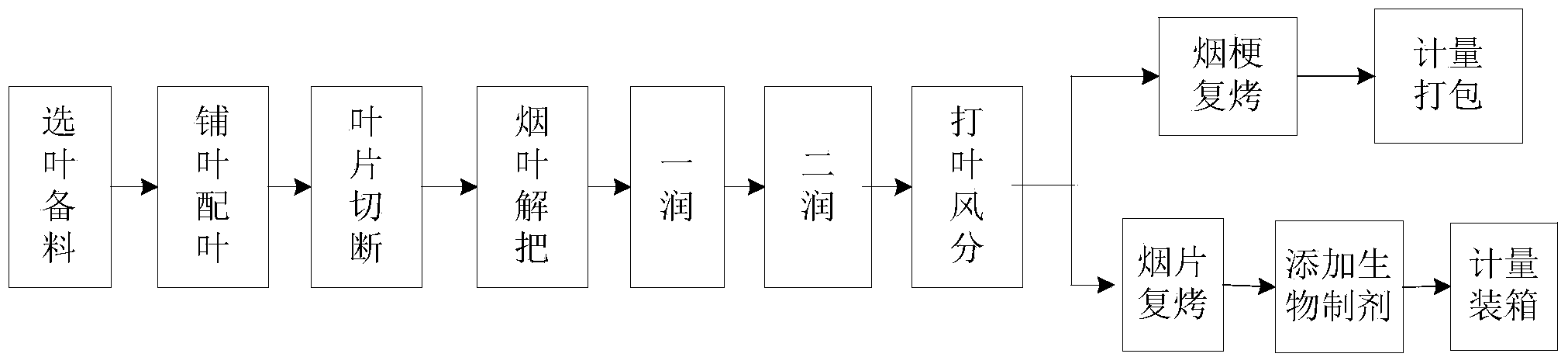

Method used

Image

Examples

Embodiment 1

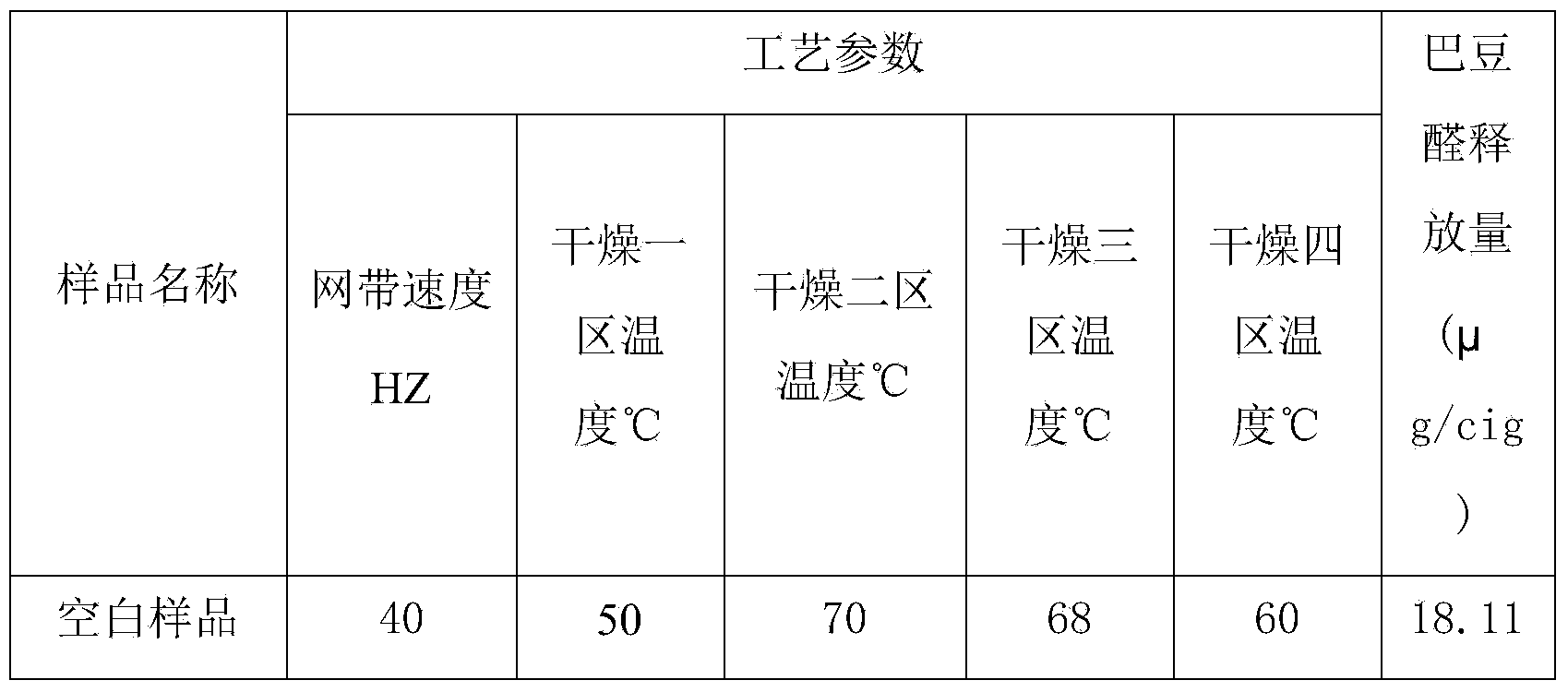

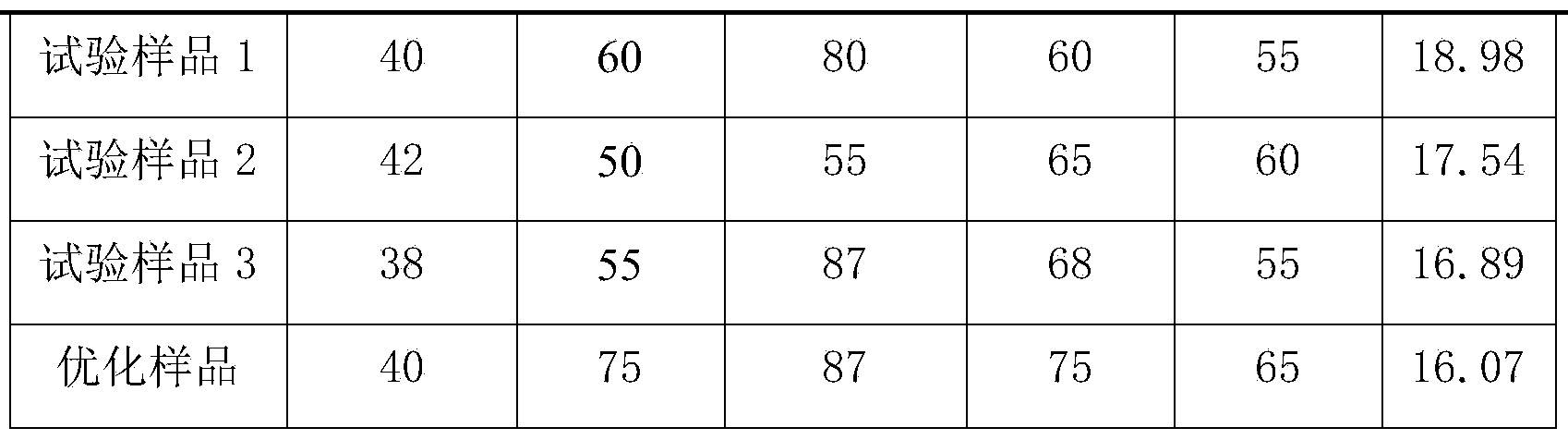

[0020] The 2011 C3L tobacco leaf sample from a certain place in the central part produced according to the existing threshing and re-baking process parameters was used as a blank sample; according to three groups of different process parameters and optimized processing parameters, the leaves were threshed and re-roasted, and the other process parameters were unchanged. The obtained tobacco leaf samples 1-3 and optimized samples; the tobacco leaf samples of each group were loosened and rehydrated under the same conditions, cut into shreds, and dried naturally, and then rolled into cigarette samples. The detection of crotonaldehyde release in smoke of the samples is shown in Table 1.

[0021] Table 1 Detection results of crotonaldehyde release between the optimized sample and the blank sample in the rebaking process

[0022]

[0023]

[0024] It can be seen from Table 1 that the amount of crotonaldehyde released in the flue gas of the tobacco samples produced under the opt...

Embodiment 2

[0026] Tobacco leaves produced according to the existing threshing and re-baking process parameters in the middle of a place in 2011 were used as blank samples; the other process parameters were unchanged, and the samples of biological reagents were added as optimized samples. bacillus and circulant bacillus, according to the mass percentage ratio of 1:1:2, water is used as solvent to prepare a 1.2‰ biological preparation aqueous solution, and the bacterial content of Bacillus megaterium in the biological preparation is 1×10 12 CFU / g, Bacillus amyloliquefaciens bacteria content 1×10 10 CFU / g, Bacillus circulans content 1×10 10 CFU / g; the samples were alcoholized under the same conditions, loosened and regained moisture under the same conditions, cut into shreds, and dried naturally, and rolled into cigarette samples. The detection of crotonaldehyde release in the smoke of the samples is shown in Table 2, and 1% in the table means that the added amount of the biological agent ...

Embodiment 3

[0032] Tobacco leaves produced according to the existing threshing and re-baking process parameters in the middle of a place in 2011 were used as blank samples; the other process parameters were unchanged, and the samples of biological reagents were added as optimized samples. Bacillus, Bacillus circulans, and Bacillus subtilis, according to the mass percentage of 1:1:1:2, with water as solvent, prepared into 0.6‰ biological preparation aqueous solution, the bacteria content of Bacillus megaterium in the biological preparation is 1× 10 12 CFU / g, Bacillus amyloliquefaciens bacteria content 1×10 10 CFU / g, Bacillus circulans content 1×10 10 CFU / g, Bacillus subtilis content 1×10 15 CFU / g; the samples were alcoholized under the same conditions, loosened and regained moisture under the same conditions, cut into shreds, and dried naturally, and rolled into cigarette samples. The detection of crotonaldehyde release in the smoke of the samples is shown in Table 3. In the table, 2% m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com