Preparation method of nickel-cobalt-manganese ternary material and anode material for lithium ion battery

A ternary material, nickel-cobalt-manganese technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high sewage treatment costs, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

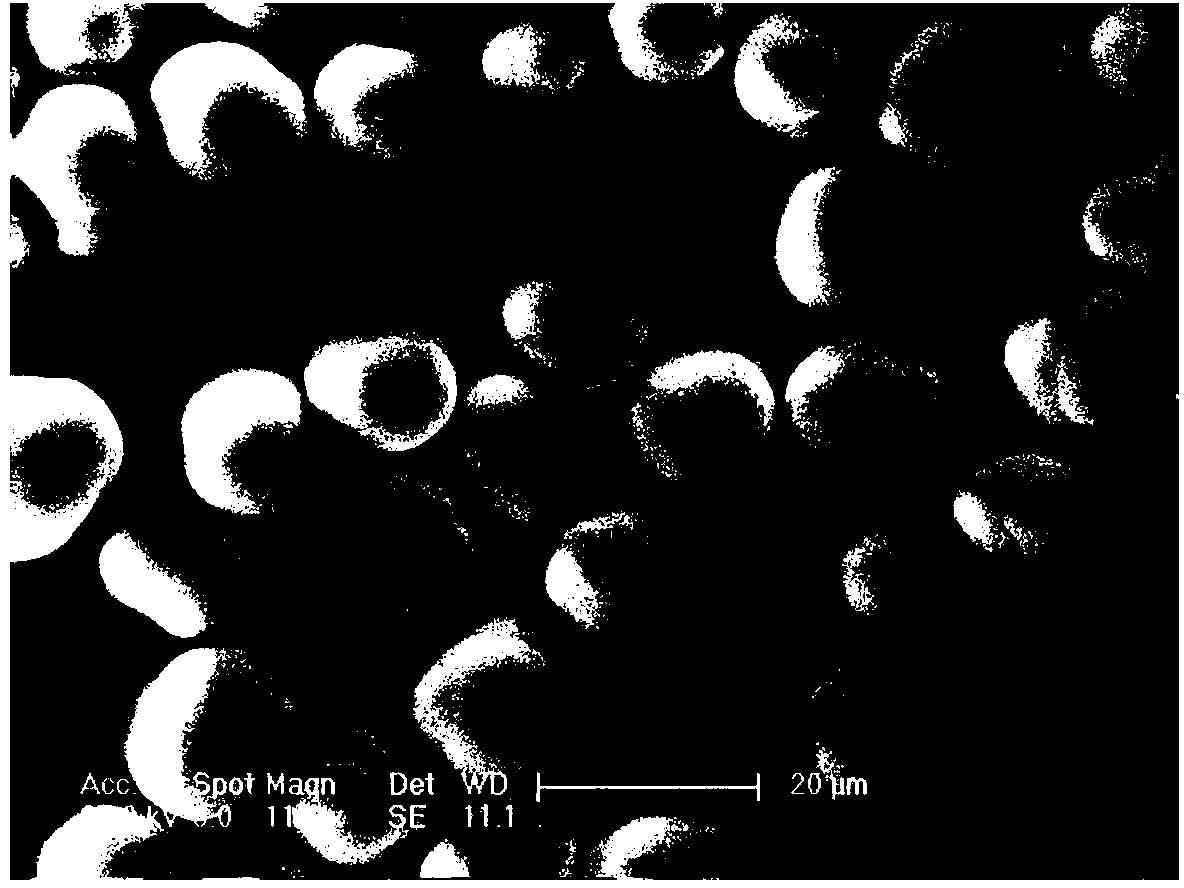

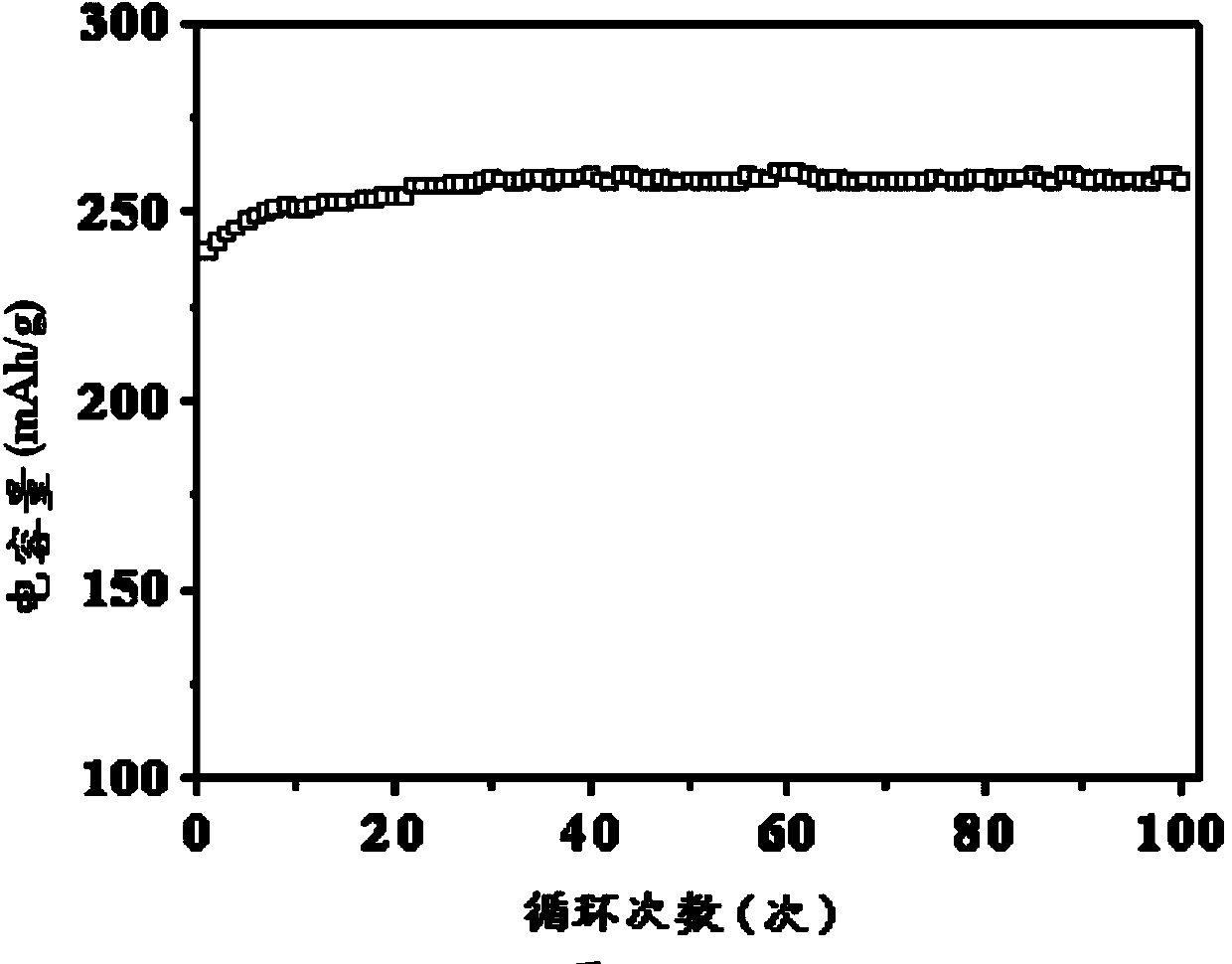

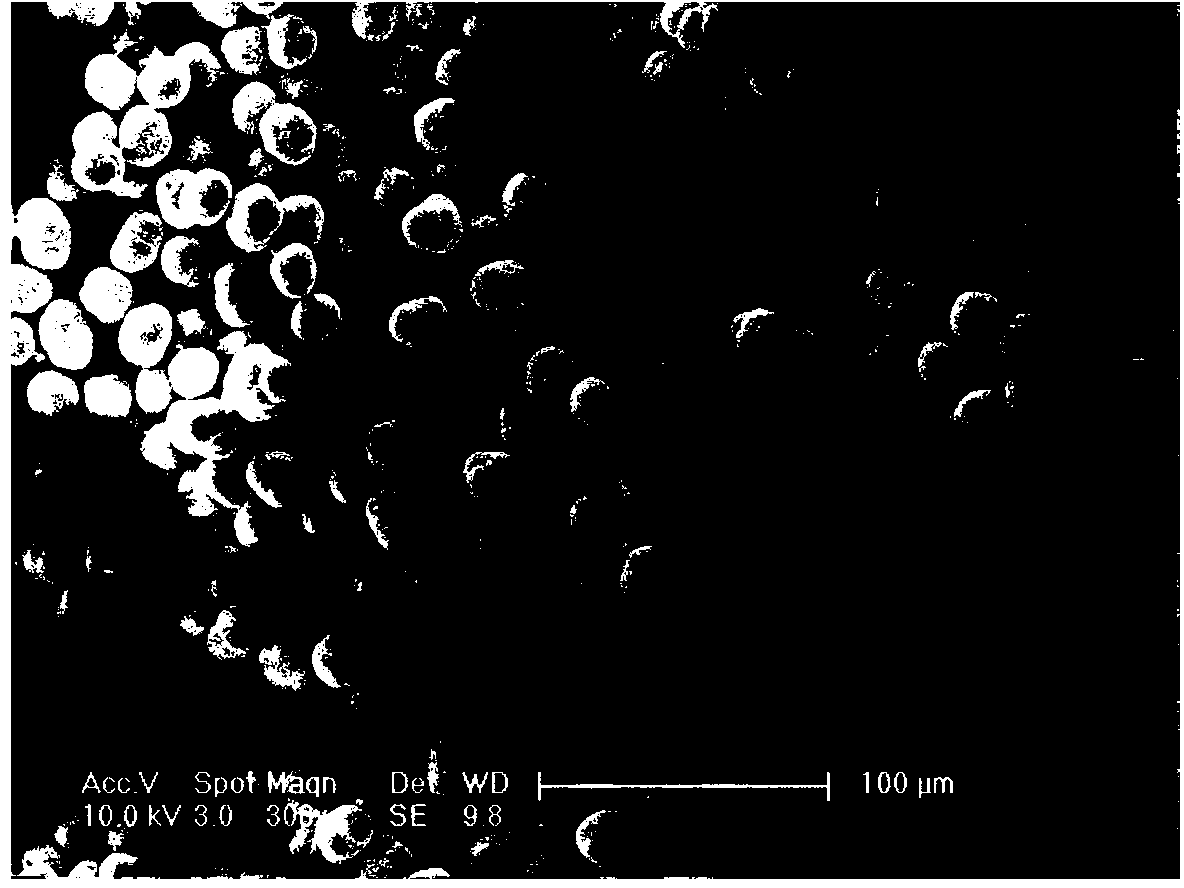

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a nickel-cobalt-manganese ternary material, comprising the following steps:

[0030] 1) Under the action of stirring, the soluble salt of nickel, soluble salt of cobalt, soluble salt of manganese and precipitant are subjected to co-precipitation reaction under the condition of pH value of 7.5-8.5 to obtain the precursor of nickel-cobalt-manganese ternary material , the stirring speed is 600 rpm to 1000 rpm, and the reaction temperature of the co-precipitation reaction is 40°C to 60°C;

[0031] 2) Calcining the nickel-cobalt-manganese ternary material precursor to obtain an intermediate product;

[0032] 3) The intermediate product is mixed with the lithium source and then sintered to obtain a nickel-cobalt-manganese ternary material.

[0033] The present invention comprehensively controls the stirring speed of the co-precipitation reaction during the preparation of the nickel-cobalt-manganese ternary material precursor, the...

Embodiment 1

[0061] Manganese sulfate, nickel sulfate and cobalt sulfate are dissolved in water to obtain a mixed solution of manganese sulfate, nickel sulfate and cobalt sulfate; the molar ratio of manganese sulfate, nickel sulfate and cobalt sulfate is 0.7:0.2:0.1, and the manganese sulfate 1. The total molar concentration of manganese ions, nickel ions and cobalt ions in the mixed solution of nickel sulfate and cobalt sulfate is 2.0mol / L;

[0062] Preparation molar concentration is the sodium carbonate aqueous solution of 2.1mol / L as precipitation agent;

[0063] The preparation molar concentration is the sodium carbonate aqueous solution of 0.15mol / L, is then adjusted its pH value with the acetic acid solution of 2.0mol / L with the molar concentration, obtains the sodium carbonate aqueous solution that the pH value is 8.3, and the molar concentration is 0.15mol / L as the reaction base liquid;

[0064] The above reaction bottom liquid was placed in a reaction kettle, the volume of the reac...

Embodiment 2

[0072] Manganese nitrate, nickel nitrate and cobalt nitrate are dissolved in water to obtain a mixed solution of manganese nitrate, nickel nitrate and cobalt nitrate; the molar ratio of manganese nitrate, nickel nitrate and cobalt nitrate is 0.65:0.15:0.2, and the manganese nitrate 1. The total molar concentration of manganese ions, nickel ions and cobalt ions in the mixed solution of nickel nitrate and cobalt nitrate is 2.0mol / L;

[0073] Preparation molar concentration is the sodium carbonate aqueous solution of 2.2mol / L as precipitation agent;

[0074] The preparation molar concentration is the sodium carbonate aqueous solution of 0.15mol / L, then with the molar concentration is the nitric acid solution of 0.5mol / L to adjust its pH value, obtains the sodium carbonate aqueous solution that the pH value is 8.3, and the molar concentration is 0.15mol / L as the reaction bottom liquid;

[0075] The above reaction bottom liquid was placed in a reactor, the volume of the reaction b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com