Equipment room floating structure

A machine room and equipment technology, applied in the field of equipment room floating structure, can solve the problems of long construction period, complicated construction process and high cost, and achieve the effects of short construction period, rich material selection and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

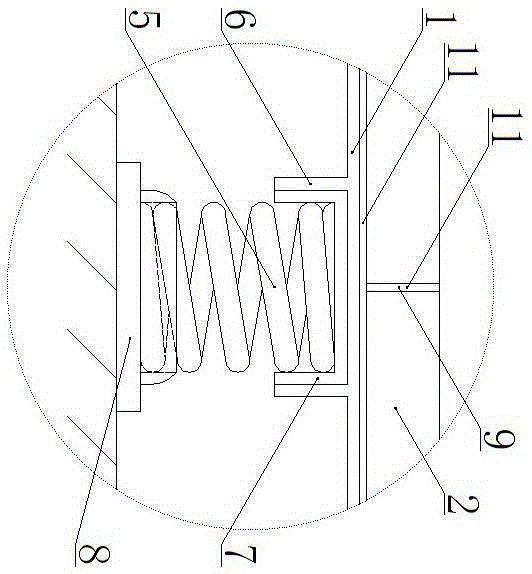

[0027] exist figure 1 , 2 In the shown embodiment, a floating structure of equipment room, elastic vibration isolation components, load-bearing steel plate structure (1), decorative quality panel (2) and the building structure facade (3) are arranged sequentially from bottom to top. ) and the elastic vibration isolation plate (4) between the load-bearing steel plate structure (1) and the decorative quality panel (2). The load-bearing steel plate structure (1) is composed of flat steel plates around corners to form a square frame, and the load-bearing steel plate structure (1) is arrayed with a plurality of elastic vibration-isolation components and fixed components. The elastic vibration isolation member is a steel spring (5), and the elastic vibration isolation member fixed member under the steel plate is a steel round tube (6), embedded with a rubber damping sleeve (7), and the outer diameter of the steel spring (5) is in line with the rubber The inner diameter of the damp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com