Modified asphalt and preparation method thereof

A technology for modifying asphalt and high-temperature asphalt, which is applied to processing tar pitch/petroleum pitch/natural pitch by distillation, processing tar pitch/petroleum pitch/natural pitch by chemical methods, and processing tar pitch/petroleum pitch/natural pitch by selective extraction and other directions, can solve the problems of poor applicability and poor adhesion of product development, achieve the effect of low softening point and avoid volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

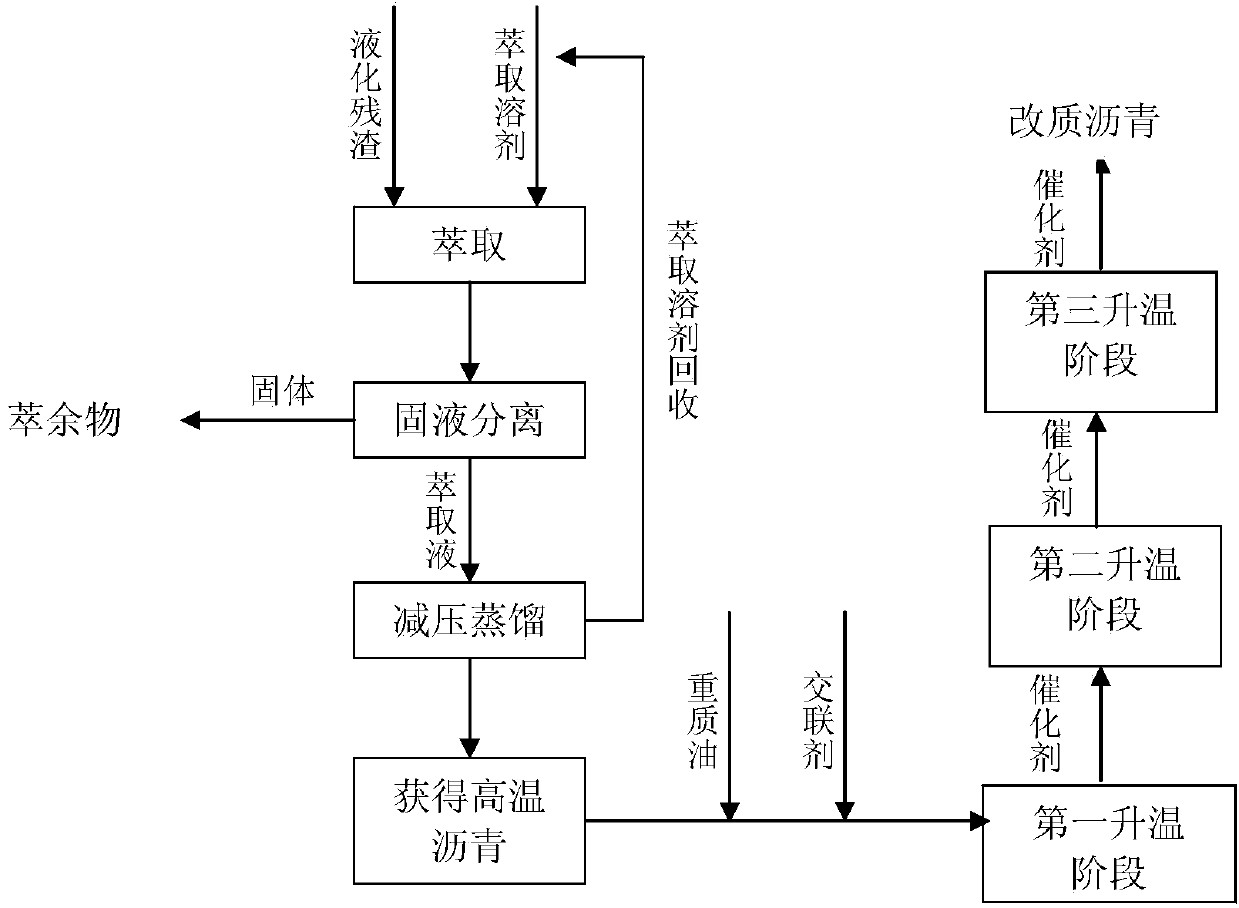

[0032] In a typical embodiment of the present invention, a method for preparing modified asphalt is provided. The preparation method includes the following steps: S1, mixing high-temperature asphalt with heavy oil and a cross-linking agent to obtain a mixture, the softening point of the high-temperature asphalt is 115-160°C, the content of beta resin is 5-15wt%, and the ash content is ≤0.5 wt%; S2, the mixture is subjected to stage-by-stage cross-linking polymerization under the action of a catalyst to obtain modified asphalt. The cross-linking polymerization temperature of different stages is different and the cross-linking polymerization temperature of each stage is between 60 and 180 °C.

[0033] As described in the background technology of the present invention, the softening point of the high-temperature bitumen produced from the residue of direct coal liquefaction is 115-160°C, the content of β resin is 5-15wt%, and the ash content is ≤0.5wt%. Compared with the prior art ...

Embodiment 1

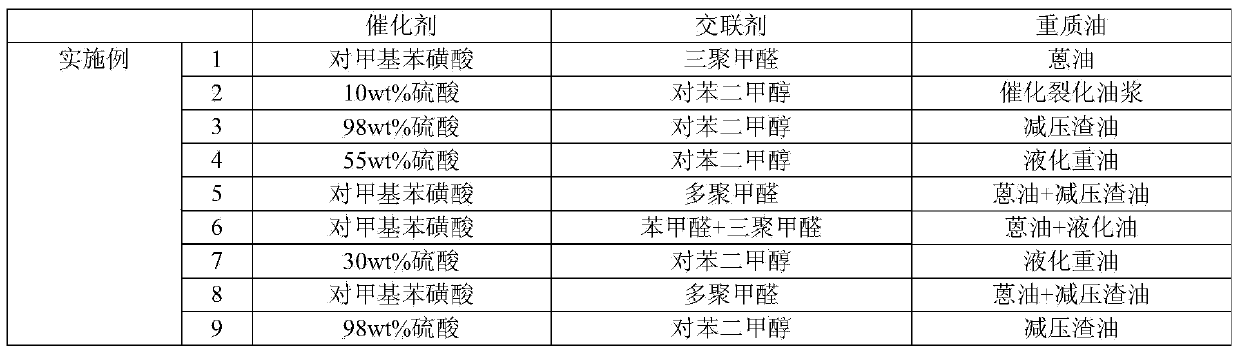

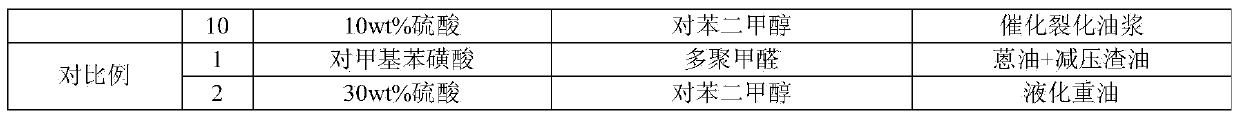

[0056] According to attached figure 1 According to the preparation process shown in , 50 g of the above-mentioned high-temperature pitch with a particle size of 0.2 mm is mixed with 2.5 g of anthracene oil and 0.5 g of paraformaldehyde to obtain a mixture; the mixture is added to a stirring tank, and under the protection of a nitrogen atmosphere, the ℃ / min heating rate (V1) to 60°C (T1), add 0.5g p-toluenesulfonic acid, cross-linking polymerization lasts 10min, then raise the temperature to 80°C (T2), then add 0.5g p-toluenesulfonic acid Sulfonic acid, cross-linking polymerization continued for 10 minutes, then the temperature was raised to 100°C (T3), and then 1 g of p-toluenesulfonic acid was added, cross-linking polymerization continued for 60 minutes, and heating was stopped to obtain the modified asphalt of Example 1.

Embodiment 2

[0058] According to attached figure 1 In the preparation process shown in , select the above-mentioned high-temperature asphalt with a particle size of 0.5mm as raw material, select the heavy oil, crosslinking agent and catalyst type in Example 2 in Table 1, and use the corresponding parameters in Table 2 according to Example 1 The steps are prepared to obtain the modified asphalt of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com