Preparation and application of a biologically functionalized hydroxypropyl cellulose ester liquid crystal film

A hydroxypropyl cellulose, hydroxypropylated technology, applied in liquid crystal materials, chemical instruments and methods, medical science and other directions, to achieve the effect of improving cell affinity, improving bioavailability, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

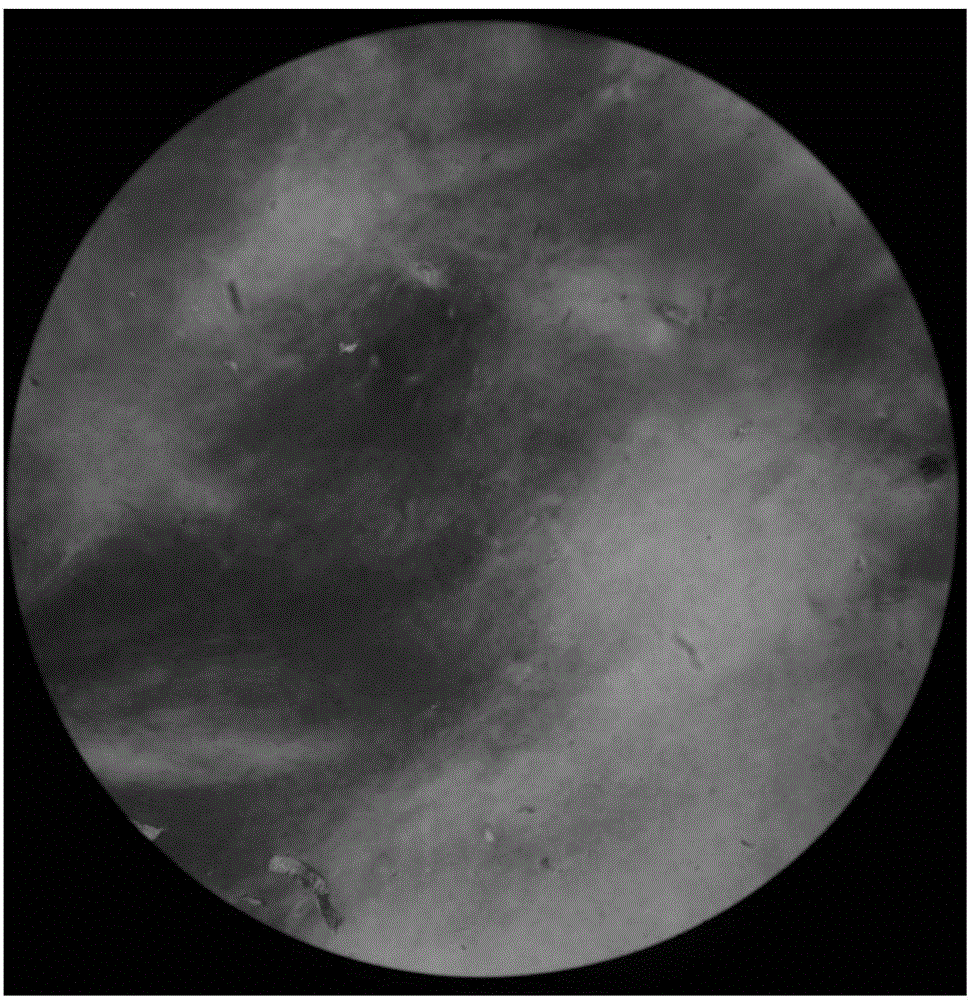

[0049] Example 1: Synthesis of hydroxypropyl cellulose propyl ester-glutaric anhydride liquid crystal and the preparation process of its surface grafted RGD-containing short peptide:

[0050] (1) 3g hydroxypropyl cellulose was reacted with 1.2mL propionyl chloride in acetone at 55°C for 6 hours with magnetic stirring, then dialyzed in water for 3 days, changing the water 3 times a day, and vacuum-dried at 50°C to obtain low Substituted for hydroxypropyl cellulose propyl ester (PPC).

[0051] (2) Dissolve 3g of low-substituted PPC in 50mL of distilled acetone and heat to 50°C, add 2g of glutaric anhydride (GA) and 0.15g of 4-lutidine to the homogeneous solution, and react for 45 minutes under magnetic stirring. The reaction product was transferred to a dialysis bag, dialyzed in ultrapure water for 3 days, and the water was changed 3 times a day. After the dialysis, the product was dried in a vacuum oven at 50°C, and the obtained product was designated as PPC-GA.

[0052] (3) P...

Embodiment 2

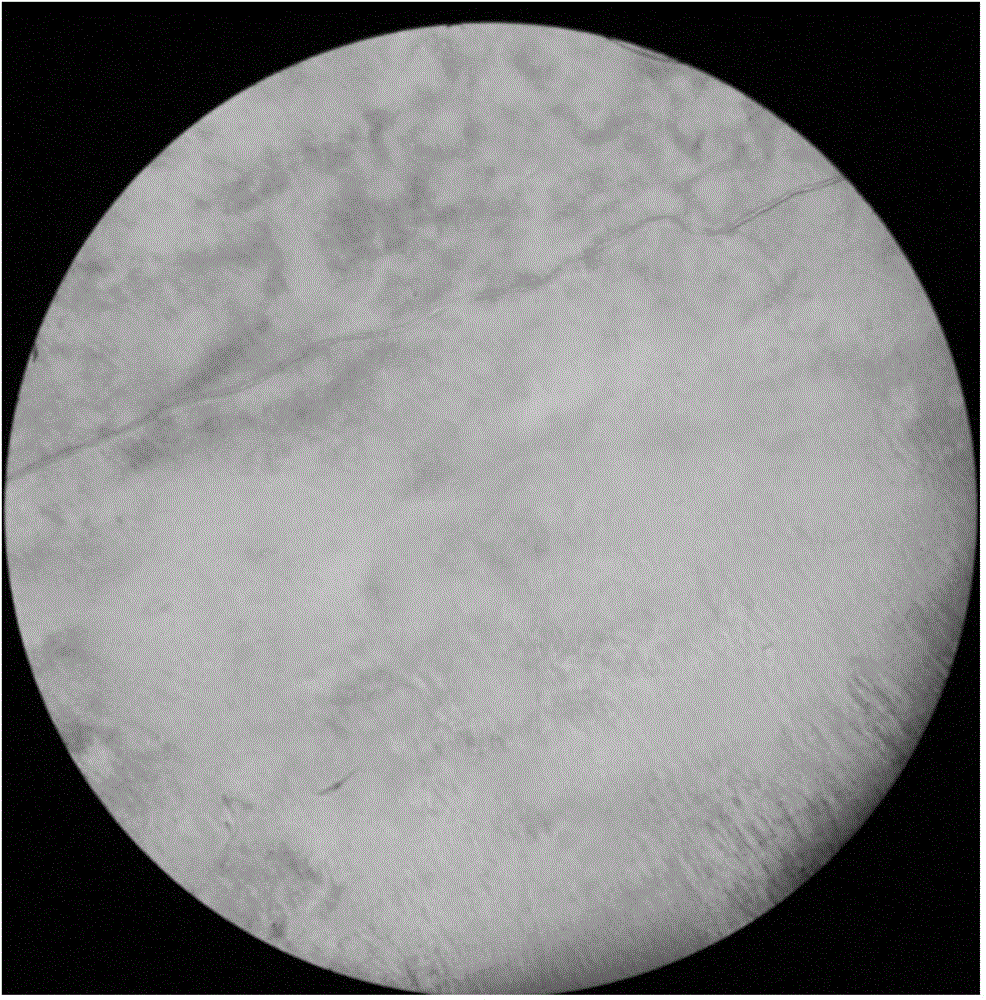

[0055] Example 2: Synthesis of hydroxypropyl cellulose butyl ester-glutaric anhydride liquid crystal and the preparation steps of its surface grafted with RGDS short peptide:

[0056] (1) 3g of hydroxypropyl cellulose was reacted with 1mL of butyryl chloride in acetone, 60°C, magnetically stirred for 5 hours, dialyzed in water, and dried in vacuum at 55°C to obtain low-substituted hydroxypropyl cellulose butyl ester (BPC ).

[0057] (2) Dissolve 3g of low-substituted BPC in 50mL of distilled acetone and heat to 50°C, add 2g of glutaric anhydride (GA) and 0.15g of 4-lutidine to the homogeneous solution, and react for 45 minutes under magnetic stirring. The reaction product was transferred to a dialysis bag, dialyzed in ultrapure water for 5 days, and the water was changed 3 times a day. After the dialysis, the product was dried in a vacuum oven at 50°C, and the obtained product was designated as BPC-GA.

[0058] (3) BPC-GA was dissolved in tetrahydrofuran to form a homogeneous...

Embodiment 3

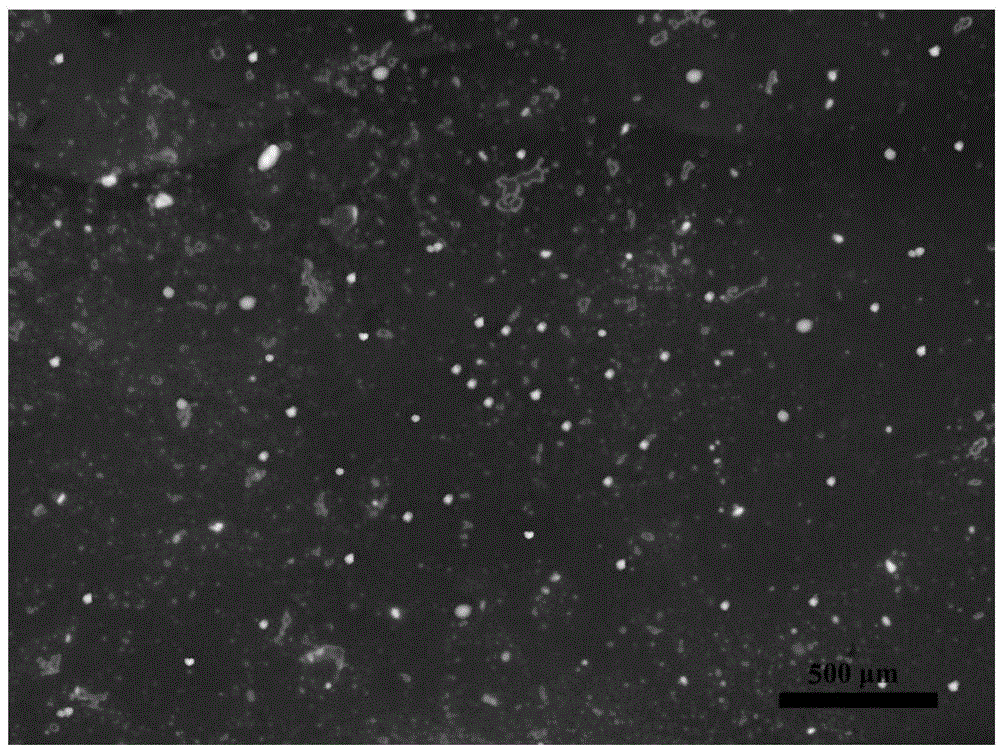

[0061] Embodiment 3: the preparation of hydroxypropyl cellulose octyl ester (OPC)-glutaric anhydride film surface grafting containing RGD short peptide, comprises the following steps:

[0062] (1) 3 g of hydroxypropyl cellulose was reacted with 1 mL of octanoyl chloride in acetone, 60 ° C, magnetically stirred for 4 hours, dialyzed in water, and dried in vacuum at 55 ° C to obtain low-substituted hydroxypropyl cellulose octyl ester (OPC ).

[0063] (2) Dissolve 5g of low-substituted OPC in 50mL of distilled acetone and heat to 50°C, add 3g of glutaric anhydride and 0.225g of 4-lutidine to the homogeneous solution, and react for 1 hour under magnetic stirring. After the reaction, the reaction product was transferred to a dialysis bag and dialyzed in ultrapure water for 5 days, changing the water 3 times a day to remove by-products and unreacted small molecules. After dialysis, the product was dried in a vacuum oven at 50°C to remove all moisture to obtain the product, which wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com