Aqueous color-developing resin emulsion, preparation method and applied coating composition

A technology of coating composition and resin emulsion, which is applied in the direction of coating, etc., can solve the problems of rising prices, adverse effects of construction and use environment, and non-competitiveness, so as to reduce dosage, improve film-forming defects, and compatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

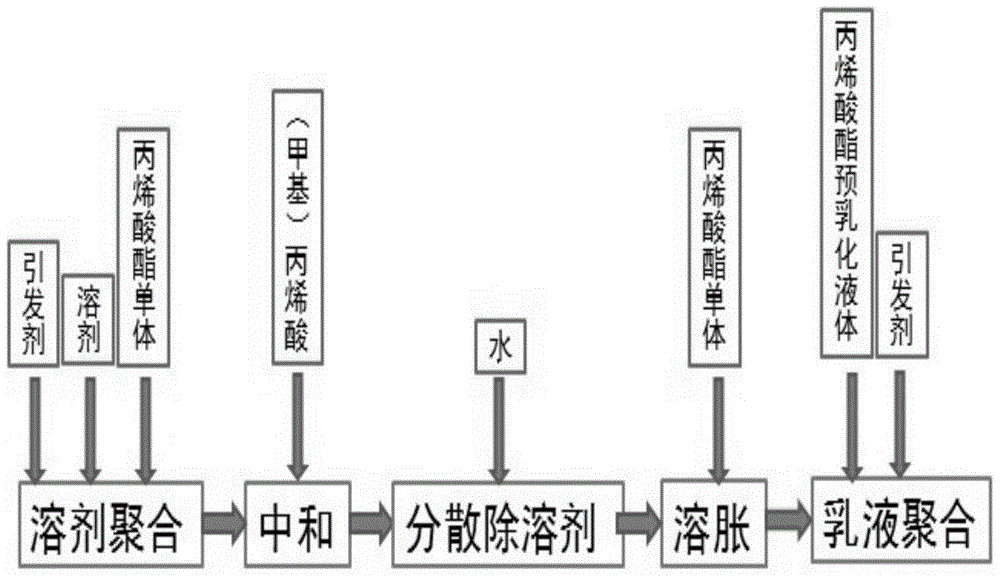

Method used

Image

Examples

Embodiment 1

[0050] (1) Add 290g ethyl acetate, 40g methyl methacrylate, 15g n-butyl acrylate, 15g n-butyl methacrylate, 26g isooctyl acrylate and 4g of dimethylaminoethyl methacrylate, mixed well, heated up to 55°C, added 10g of 0.5wt% azobisisobutyronitrile-ethyl acetate solution, and reacted for 3h;

[0051] (2) Lower the system 1 to room temperature, add 2.5g of methacrylic acid, and stir for 0.5h;

[0052] (3) Use a vacuum pump to extract the solvent at 65°C. When the extracted solvent is between 100 and 170g, remove the vacuum device and stir at a high speed (high-speed stirring is based on the ability to completely and evenly disperse the prepolymer in water) Add 300g of water to obtain a water dispersion, and continue to use a vacuum pump to extract the remaining solvent;

[0053] (4) Use 15g of n-butyl acrylate and 15g of n-butyl methacrylate to swell the water dispersion in system 3;

[0054] (5) Use system 4 as the seed emulsion, add 10g of 1wt% ammonium persulfate aqueous sol...

Embodiment 2

[0059] (1) Add 290g ethyl acetate, 60g methyl methacrylate, 10g n-butyl acrylate, 10g n-butyl methacrylate, 16g isooctyl acrylate and 4g of dimethylaminoethyl methacrylate, mixed well, heated up to 55°C, added 0.5wt% azobisisobutyronitrile-ethyl acetate, 10g, and reacted for 3h;

[0060] (2) Cool system 1 to room temperature, add 1.85g of acrylic acid, and stir for 0.5h;

[0061] (3) Use a vacuum pump to extract the solvent at 65°C. When the extracted solvent is between 100 and 170g, remove the vacuum device and stir at a high speed (high-speed stirring is based on the ability to completely and evenly disperse the prepolymer in water) Add 300g of water to obtain a water dispersion, and continue to use a vacuum pump to extract the remaining solvent;

[0062] (4) Use 5g of n-butyl acrylate and 25g of n-butyl methacrylate to swell the water dispersion in system 3;

[0063] (5) Use system 4 as the seed emulsion, add 10g of 1wt% ammonium persulfate aqueous solution, raise the tem...

Embodiment 3

[0068] (1) Add 290g ethyl acetate, 10g methyl methacrylate, 40g n-butyl acrylate, 40g n-butyl methacrylate, 6g isooctyl acrylate and 4g of dimethylaminoethyl methacrylate, mixed well, heated up to 55°C, added 0.5wt% azobisisobutyronitrile-ethyl acetate, 10g, and reacted for 3h;

[0069] (2) Cool system 1 to room temperature, add 1.85g of acrylic acid, and stir for 0.5h;

[0070] (3) Use a vacuum pump to extract the solvent at 65°C. When the extracted solvent is between 100 and 170g, remove the vacuum device and stir at a high speed (high-speed stirring is based on the ability to completely and evenly disperse the prepolymer in water) Add 300g of water to obtain a water dispersion, and continue to use a vacuum pump to extract the remaining solvent;

[0071] (4) Use 30g of the aqueous dispersion in n-butyl acrylate swelling system 3;

[0072] (5) Use system 4 as the seed emulsion, add 10g of 1wt% ammonium persulfate aqueous solution, raise the temperature to 80°C, and react fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

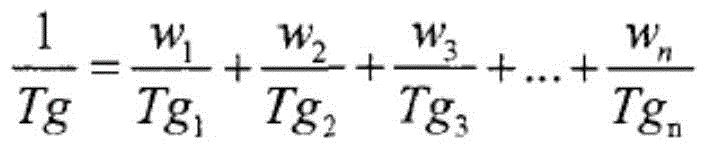

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com