A method for producing isoborneol

A production method and technology of isoborneol, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the problem of low selectivity, long reaction time, and difficulty in separation, etc. problems, to achieve the effect of reaction conversion rate and selectivity improvement, high selectivity and conversion rate, avoiding corrosion and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

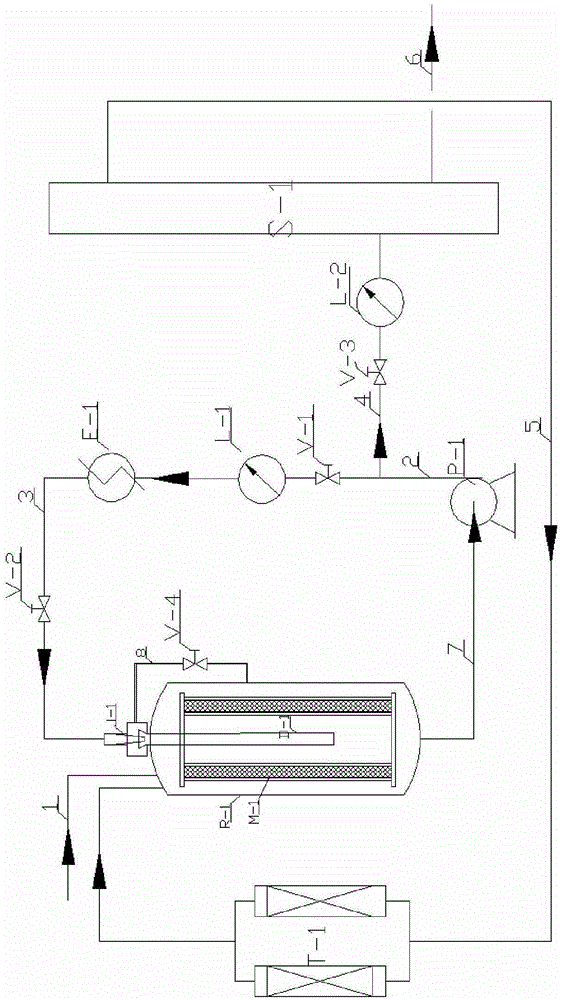

Embodiment 1

[0033] In the reaction system IRR, the volume of liquid flow enhanced submerged fixed bed reactor is 2m 3 (wherein the length-to-diameter ratio is 3:1), camphene, water and solvent enter the reactor at a mass ratio of 1:1:2 for reaction (the total mass is 1.4t). The catalyst bed is filled with a composite of two solid catalysts, Amberlyst15 and HZSM-5. The mass ratio of the two catalysts is 1:1, and the total mass is 35% (about 490kg) of the total liquid material mass of the first filler. The solvent is a compound of chloroform and methyl ethyl ketone, and the molar ratio is 1:0.5. The reaction temperature is 55° C., the pressure is 0.1 MPa, and the average residence time of the reaction materials in the reactor is 55 minutes. The self-priming interface 8 is set at 1 / 3 above the busbar on the outer wall of the reactor. The circulating volume of circulation pump P-1 per hour is 20 times of the total material (including solvent) in the reactor (about 30m 3 / h). The reacted m...

Embodiment 2

[0035] In the same reaction system IRR as in Example 1, the liquid flow enhanced submerged fixed bed reactor volume is 4m 3 (where the aspect ratio is 2.5:1), camphene, water and solvent enter the reactor at a mass ratio of 1:0.15:2 (the total mass is 2.8t) for reaction. The catalyst bed is filled with a composite of three solid catalysts, Amberlyst35, D72 and ZSM-35. The mass ratio of the three catalysts is 1:0.5:1, and the total mass is 28% (about 790kg) of the total mass of the liquid material loaded for the first time. The solvent is a compound of chloroform, nitroethane and acetonitrile, and the molar ratio is 1:0.5:0.5. The reaction temperature is 45° C., and the pressure is 0.12 MPa. The average residence time of the reaction materials in the reactor is 1 h. The self-priming interface 8 is set at 1 / 3 above the busbar on the outer wall of the reactor. The circulating volume of circulation pump P-1 per hour is 15 times of the total material (including solvent) in the r...

Embodiment 3

[0037] In the same reaction system IRR as in Example 1, the liquid flow enhanced submerged fixed bed reactor volume is 3m 3 (The aspect ratio is 4:1). Camphene, water and solvent enter the reactor at a mass ratio of 1:0.15:1 (about 2.1t) for reaction. The catalyst bed is loaded with a composite of three solid catalysts, Amberlyst36, NKC-9 and MCM-41, the mass ratio of the three catalysts is 1:1:1, and the total mass is 25% of the mass of the total liquid material loaded for the first time (about 530kg ) The solvent is a compound of dimethylformamide, chloroacetonitrile and nitromethane, and the molar ratio is 1:0.5:1. The reaction temperature is 88° C., the pressure is 0.25 MPa, and the average residence time of the reaction materials in the reactor is 65 minutes. The circulating volume of circulation pump P-1 per hour is 16 times (about 32t / h) of the total material (including solvent) in the reactor. The reacted material is discharged through the pipeline 4 and the valve V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com