Thin film volume acoustic wave harmonic oscillator structure and manufacturing method thereof

A thin-film bulk acoustic wave and resonator technology, applied in the field of microelectronics, can solve the problems of large area of silicon integrated circuits, reduce chip area, and insufficient reliability, so as to improve circuit performance, simplify manufacturing process, improve yield and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

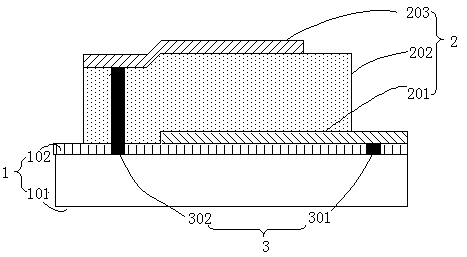

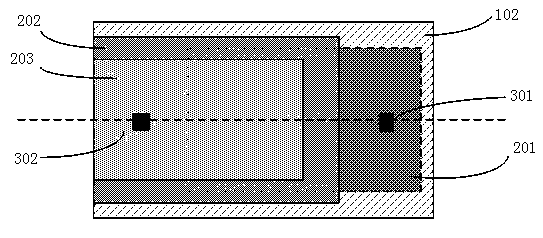

[0029] Such as figure 1 with figure 2 The thin film bulk acoustic resonator structure shown includes a substrate 1 and a piezoelectric stack 2 arranged on the surface of the substrate 1. The substrate 1 includes an integrated circuit chip 101 capable of processing the signal of the thin film bulk acoustic resonator and deposited and solidified on the integrated circuit. The polyimide layer 102 on the surface of the circuit chip 101, preferably, the thickness of the polyimide layer 102 is 1-70 μm, the integrated circuit chip 101 and the piezoelectric stack 2 are connected through the interconnection via hole 3, and the interconnection via hole 3 is filled with a conductive medium, and the conductive medium is tungsten. The integrated circuit of the integrated circuit chip 101 and the piezoelectric stack 2 realize the circuit connection through the interconnection hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com