A process method of replacing the heat tracing method of the jacket with the heat tracing method of the external heat tracing pipe

A process method and technology of heat tracing pipes, which are applied in the directions of pipe heating/cooling, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of no product and heat tracing plan, and achieve flexible heat tracing plan and heat transfer area. Big, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

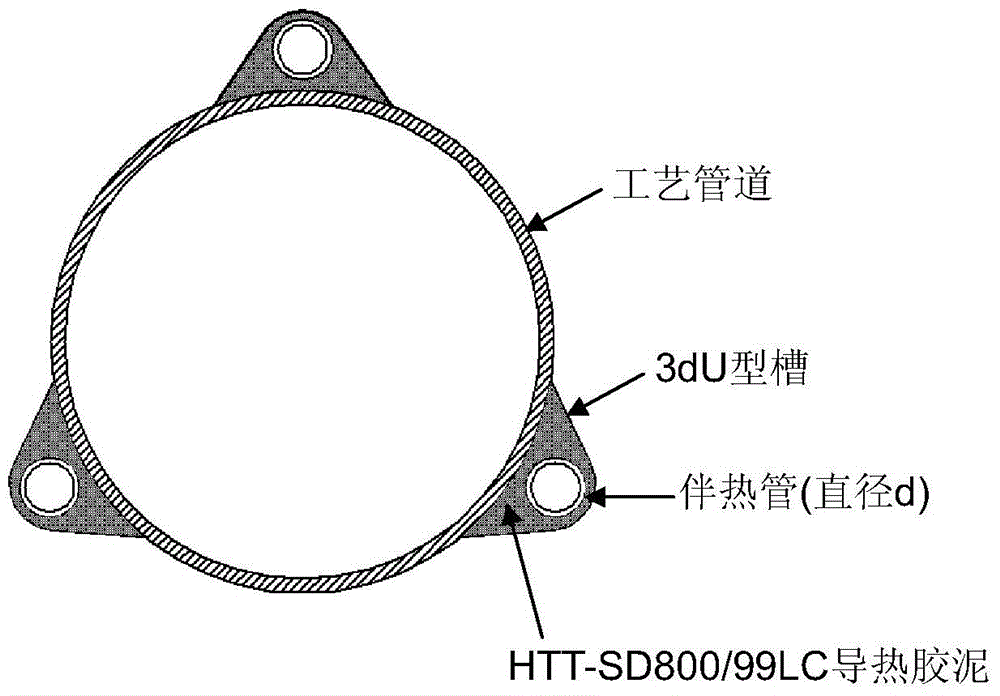

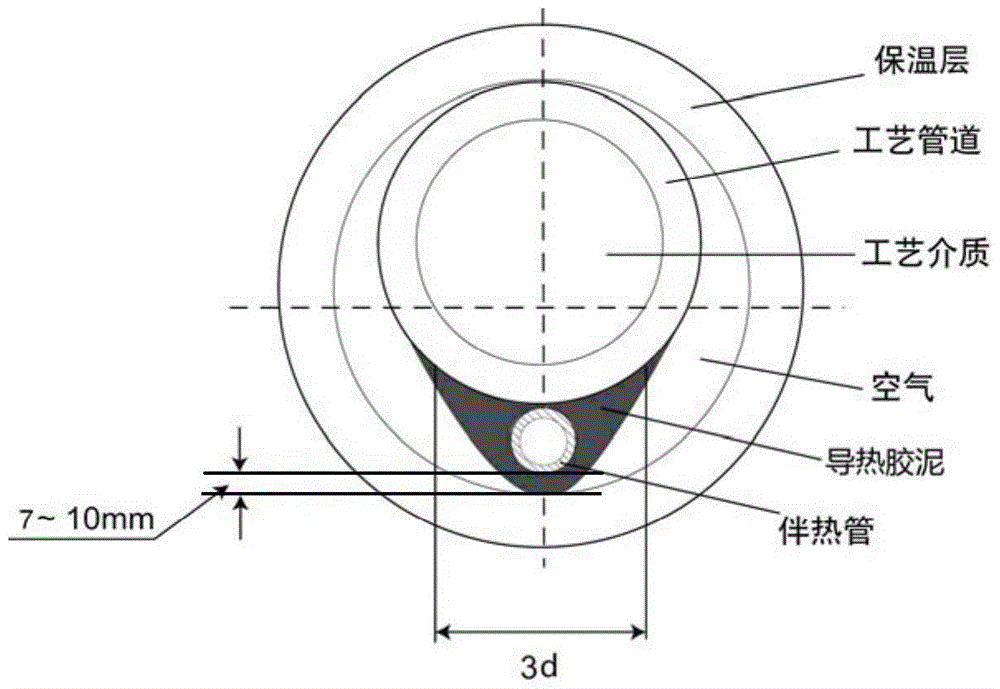

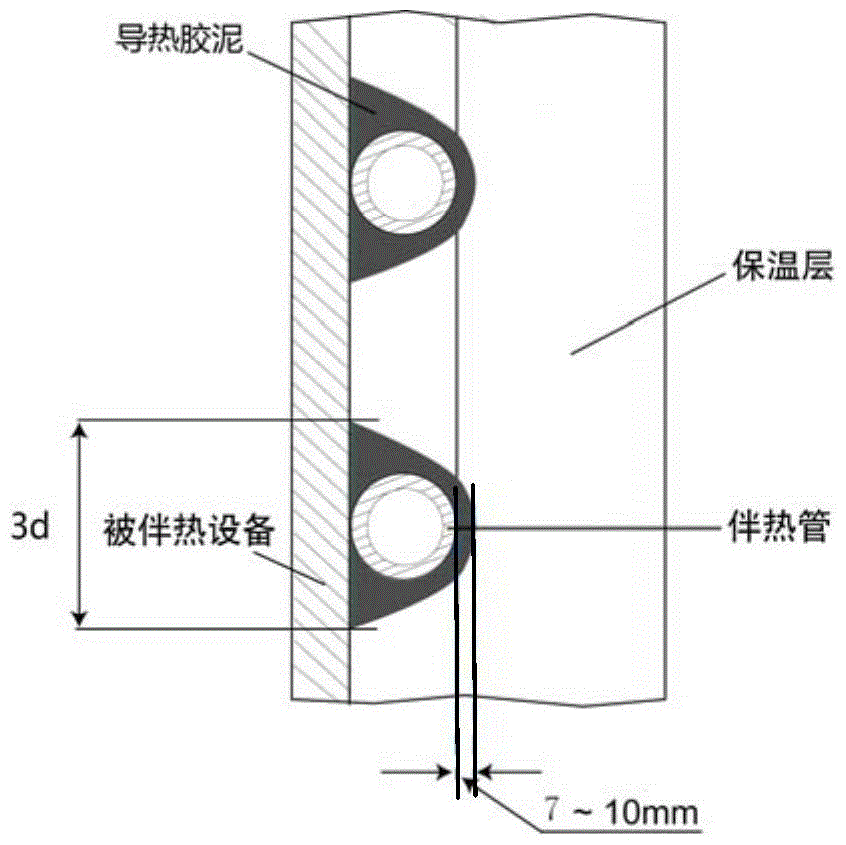

[0036] See figure 1 — Figure 4 , the present invention uses an external heat tracing tube heat tracing method instead of a jacket heat tracing method, the specific steps of the method are as follows:

[0037] Step 1: According to various production process requirements and local climate and environment conditions:

[0038]

[0039] Then calculate the number of heat tracing pipes in the HTT-SUPERSEDE heat tracing system according to the heat tracing pipe diameter and heat tracing pipe number calculation formula in the petrochemical plant process piping installation design manual, and then carry out the calculation results through ANYSYS finite element analysis and simulation Approve the correction.

[0040] Calculated according to the heat tracing conditions, when the heat tracing temperature is required to be 170°C, the outer diameter of the external heat tracing pipe is required to be

[0041] d = 1.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com