Non-active pressure-boosting pressure-stabilizing system capable of alleviating cavitation abrasion of water lubricated main-pump bearing

A passive, water-lubricated technology, applied to bearing components, shafts and bearings, bearing assembly, etc., can solve problems that have not been reported, and achieve the effect of simple and reasonable process, alleviating cavitation wear, and less control parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

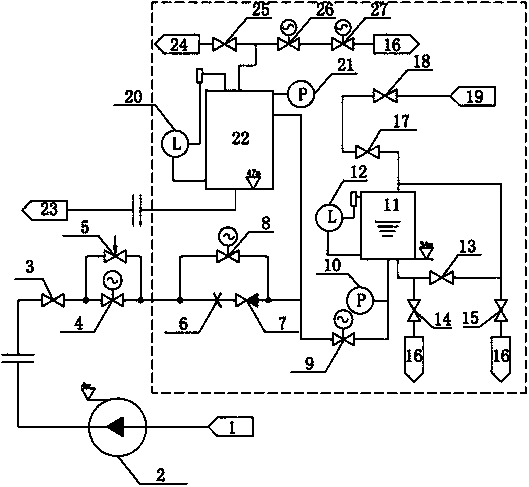

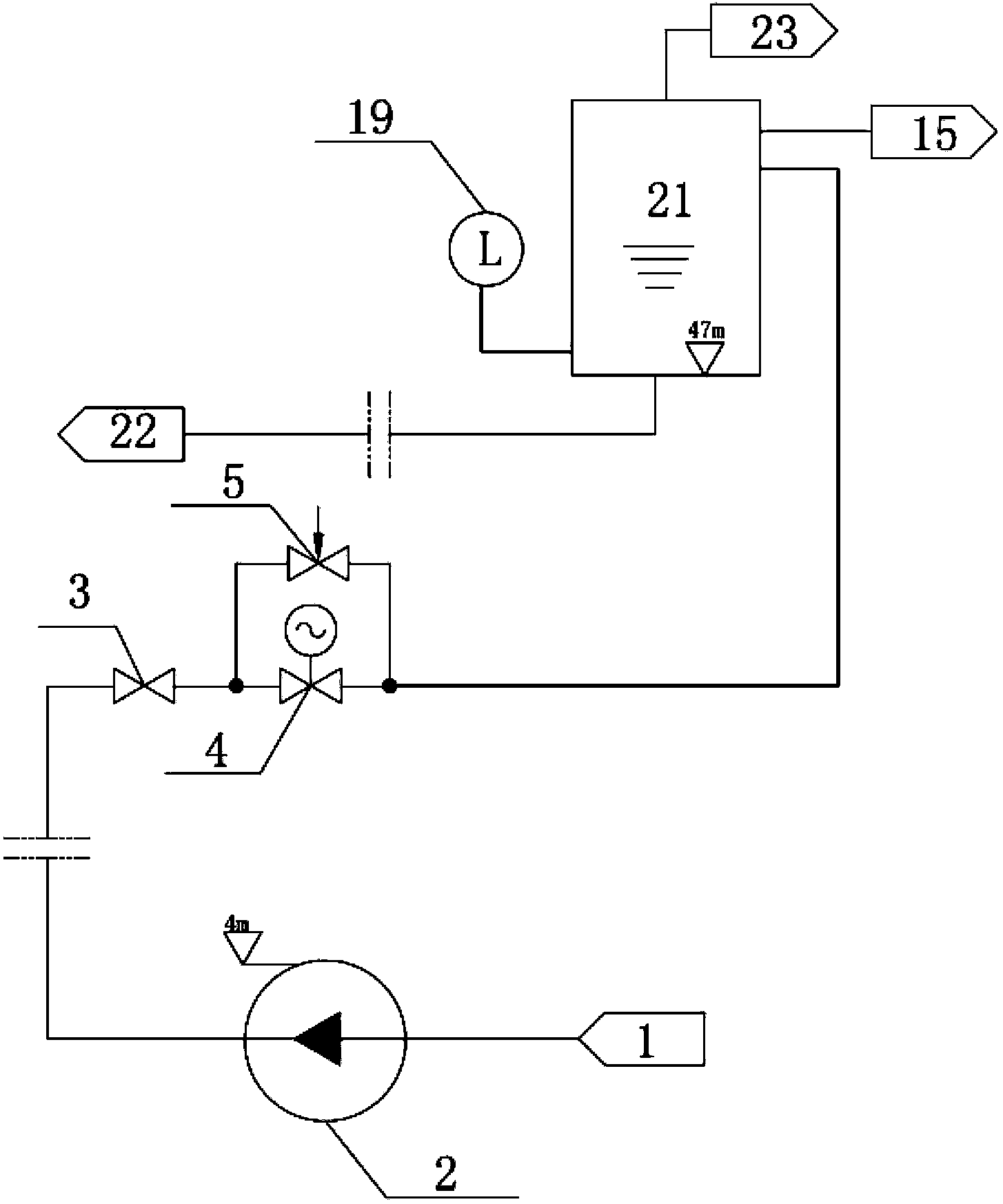

[0018] Such as figure 1 As shown, before the modification of the present invention, the desalted water in the desalted water purification system 1 is driven by the LCU pump 2 to reach the main pump head box 22 at a height of 47m through a series of valves and pipelines, and the 47m of the main pump head box 22 The height provides a certain static pressure source for the main pump bearing chamber 23 . The main pump head box 22 directly communicates with the atmosphere 24 through the exhaust pipeline, and is connected to the sump 16 through the normally open overflow pipeline. On the replenishment pipeline of the main pump head box 22, a manual cut-off valve A3 for cutting off the replenishment water, a manual adjustment valve 5 for regulating the replenishment water flow, and an electric cut-off valve A4 connected in parallel with the manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com