Evaporation drum of a coating machine

A technology of evaporation drum and coating machine, applied in the field of machinery, can solve the problems of difficult to guarantee the sealing of the interface, prolong the preparation time of the coating roller, and complicated the processing technology of the coating roller, and achieve high processing efficiency, short preparation time, and coating quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

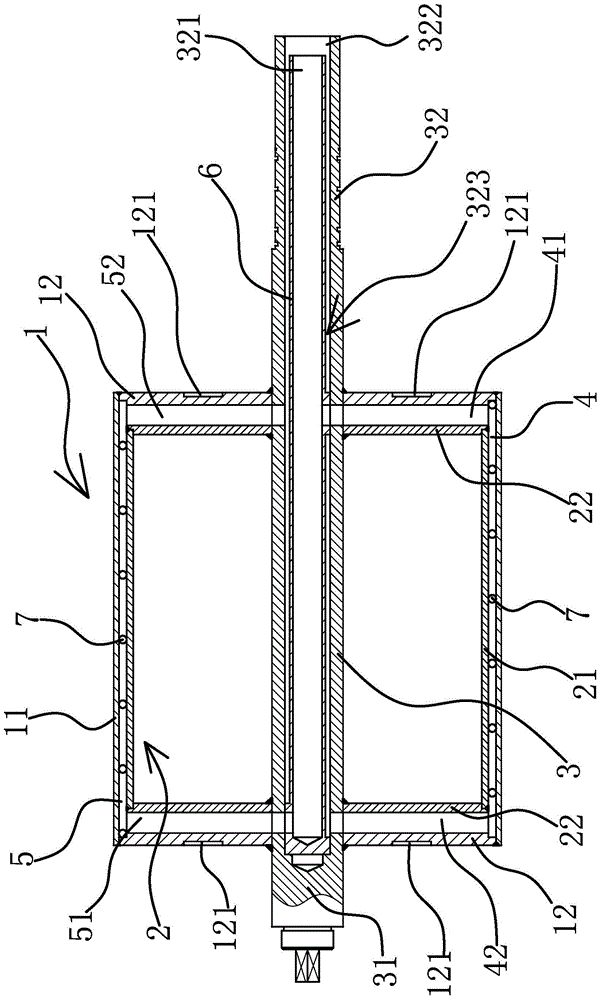

[0028] The evaporation drum of the coating machine is set on the vacuum coating machine, which is used for positioning and cooling the plastic film in the coating process. The evaporation drum of the coating machine includes an outer cylinder 1, an inner cylinder 2 and a central shaft 3.

[0029] Specifically, as figure 1 As shown, the outer cylinder 1 is sleeved on the inner cylinder 2, and a barrier member 7 is arranged between the outer cylinder 1 and the inner cylinder 2, and the barrier member 7 separates the gap between the outer cylinder 1 and the inner cylinder 2 to form a cooling channel 4 and the second cooling channel 5, the first cooling channel 4 and the second cooling channel 5 are distributed in a double-helical shape along the axial direction of the evaporation drum. In this embodiment, the barrier member 7 is round steel, which is convenient to form and easy to process. As a preferred solution, the first cooling channel 4 and the second cooling channel 5 hav...

Embodiment 2

[0035] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1. The difference lies in that in this embodiment, both the outer cylinder 1 and the inner cylinder 2 are of split structure. Specifically, the inner cylinder 2 includes an inner cylinder body 21 and inner end caps 22 located on both sides of the inner cylinder body 21. The inner side surface of the inner end cap 22 has a positioning groove 1, and the two ends of the inner cylinder body 21 are snapped into corresponding and fixedly connected with the inner end cover 22 by welding. The outer cylinder 1 includes an outer cylinder body 11 and outer end caps 12 located on both sides of the outer cylinder body 11. The end cover 12 is welded, and the inner surface of the outer end cover 12 has a second positioning groove, and the two ends of the barrier member 7 respectively abut against the second positioning groove. The dynamic balance counterweight grooves 121 are opene...

Embodiment 3

[0037] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1 or Embodiment 2. The difference lies in that in this embodiment, the barrier member 7 is a partition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com