Reconstituted tobacco chlorine ion regulation and control method

A technology for reconstituted tobacco leaves and chloride ions, which is applied in the directions of tobacco, tobacco preparation, and tobacco treatment, can solve the problems of high chloride ion content in reconstituted tobacco leaves, difficult to control, etc., and achieves the effects of high availability, increased usage, and good flammability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

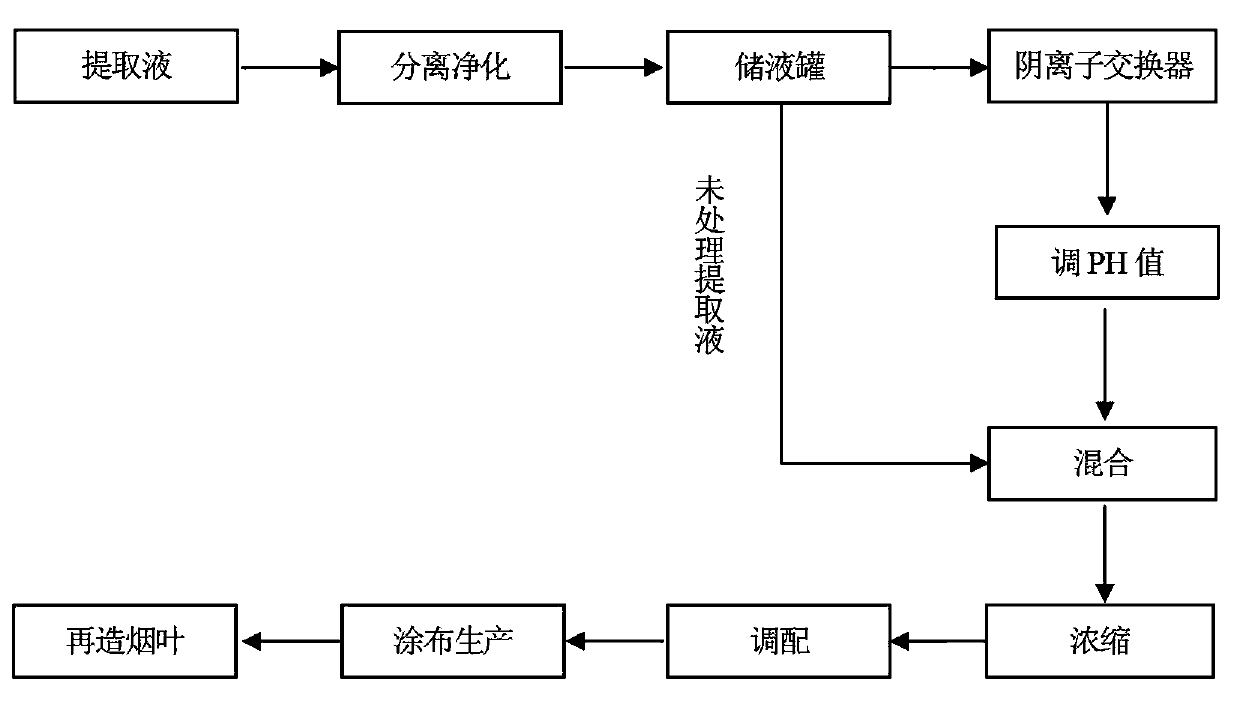

[0017] Such as figure 1 As shown, a method for regulating the chloride ion of reconstituted tobacco leaves in the present invention is to use ion exchange technology to process the extract of reconstituted tobacco leaves, remove the chloride ions in the extract, and realize the regulation and control of the chloride ion content of reconstituted tobacco leaves. The steps of the method are as follows:

[0018] 1) The extract produced in the extraction section of the reconstituted tobacco leaf production process is separated and purified to remove suspended solids and then stored in a liquid storage tank;

[0019] 2) Pass the purified extract in the liquid storage tank through an anion exchanger according to the proportion of 90% of the total mass for ion exchange to remove chloride ions in the liquid; the anion exchanger uses styrene anion resin and sodium hydroxide to regenerate;

[0020] 3) Adjust the pH value of the extract after anion exchange treatment to 6 with malic acid...

Embodiment 2

[0023] A method for regulating and controlling chlorine ions in reconstituted tobacco leaves, the method steps are as follows:

[0024] 1) Separating and purifying the extract produced in the extraction section of the reconstituted tobacco leaf production process to remove suspended solids;

[0025] 2) Pass 20% of the total mass of the purified extract through an anion exchanger for ion exchange to remove chloride ions in the liquid; the anion exchanger uses styrene anion resin and is regenerated with sodium hydroxide;

[0026] 3) Adjust the pH value of the extract solution after anion exchange treatment to 8 with malic acid;

[0027] 4) Mix 20% of the extracted solution after adjusting the pH value with 80% of the extracted solution that has not undergone ion exchange treatment;

[0028] 5) Concentrate and adjust the mixed extract before entering the coating production to prepare reconstituted tobacco leaves. The coating amount of reconstituted tobacco leaf products is contr...

Embodiment 3

[0030] A method for regulating and controlling chlorine ions in reconstituted tobacco leaves, the method steps are as follows:

[0031] 1) Separating and purifying the extract produced in the extraction section of the reconstituted tobacco leaf production process to remove suspended solids;

[0032] 2) Pass 30% of the total mass of the purified extract through an anion exchanger for ion exchange to remove chloride ions in the liquid; the anion exchanger uses styrene anion resin and is regenerated with sodium hydroxide;

[0033] 3) Adjust the pH value of the extract after anion exchange treatment to 7.5 with malic acid;

[0034] 4) Mix 30% of the extracted solution after adjusting the pH value with 70% of the extracted solution that has not undergone ion exchange treatment;

[0035] 5) Concentrate and blend the mixed extract before entering the coating production to prepare reconstituted tobacco leaves. The coating amount of reconstituted tobacco leaf products is controlled at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com