Radiation curable pressure sensitive adhesive sheet

A pressure-sensitive adhesive, radiation curing technology, used in film/sheet adhesives, adhesives, non-polymer organic compound adhesives, etc. To achieve the effect of good hardness and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

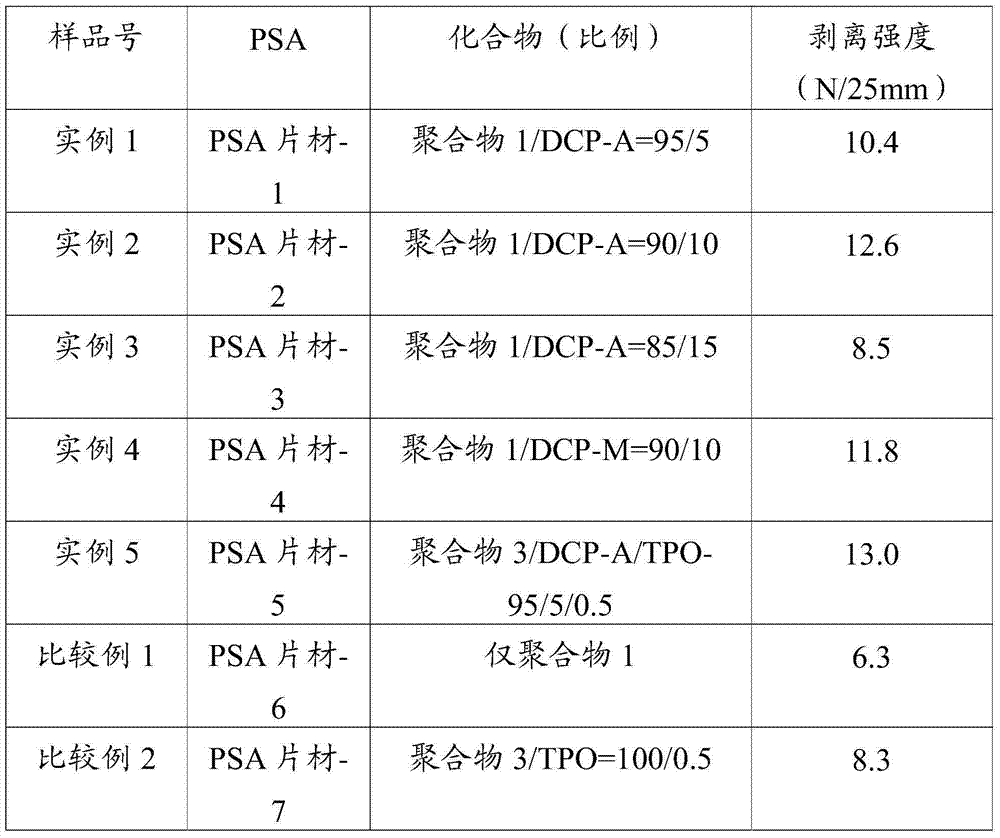

[0107] Hereinafter, the present invention is described in further detail using examples, but the present invention is not limited by these examples.

[0108] Monomer and Initiator Abbreviations

[0109] 2-EHA: 2-ethylhexyl acrylate

[0110] ISTA: Isostearyl acrylate (available from Osaka Organic Chemical Industry Ltd.)

[0111] AA: Acrylic

[0112] AEBP: 4-Acryloyloxyethoxybenzophenone

[0113] DCP-A: Tricyclodecane dimethanol diacrylate

[0114] DCP-M: Tricyclodecane dimethanol dimethacrylate

[0115]SR-399: dipentylerythritol pentaacrylate (available from Sartomer)

[0116] V-65: thermal initiator (2,2'-oxazolbis(2,4-dimethylvaleronitrile)) (available from Wako Pure Chemical Industries, Ltd.)

[0117] MOI: 2-isocyanatoethyl methacrylate (available from Showa Denko)

[0118] TPO: 2,4,6-trimethylbenzoyldiphenylphosphine oxide

[0119] EtOAc: ethyl acetate

[0120] MEK: methyl ethyl ketone

[0121] Preparation process

preparation example 1

[0123] A pressure-sensitive adhesive sheet (PSA sheet 1) was prepared as follows. Acrylic copolymers were synthesized comprising monomers of acrylates with UV crosslinkable sites as radiation reactive sites. 4-Acryloyloxyethoxybenzophenone was used as acrylate with UV crosslinkable sites.

[0124] Prepare a mixture of 2-EHA / ISTA / AA / AEBP at a ratio of 37.5:50.0:12.5:0.95 (by mass), and then use ethyl acetate / methyl ethyl ketone (EtOAc:MEK = 20 mass %:80 mass % %) mixed solvent to obtain a monomer concentration of 45% by mass. Next, V-65 was added as an initiator in an amount of 0.2% by mass relative to the mass of the monomer component, and the system was purged with nitrogen for 10 minutes. The reaction was allowed to proceed for 24 hours at 50 °C in a constant temperature bath to obtain a clear viscous solution. The obtained acrylic copolymer (polymer 1) had a weight average molecular weight of 210,000 (polystyrene equivalent, measured by gel permeation chromatography).

...

preparation example 2

[0128] A transfer adhesive strip (PSA sheet 2) was prepared in the same manner as PSA sheet 1, except that the ratio of solid polymer component to DCP-A was adjusted to 90:10 (by mass).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com