Cable-stayed bridge system in construction stage

A construction stage, cable-stayed bridge technology, applied in the direction of cable-stayed bridges, bridges, bridge construction, etc., can solve the problems of high cost and complicated construction process, achieve simple construction, ensure construction quality, and reduce the effect of vibration control engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in further detail below in conjunction with accompanying drawing:

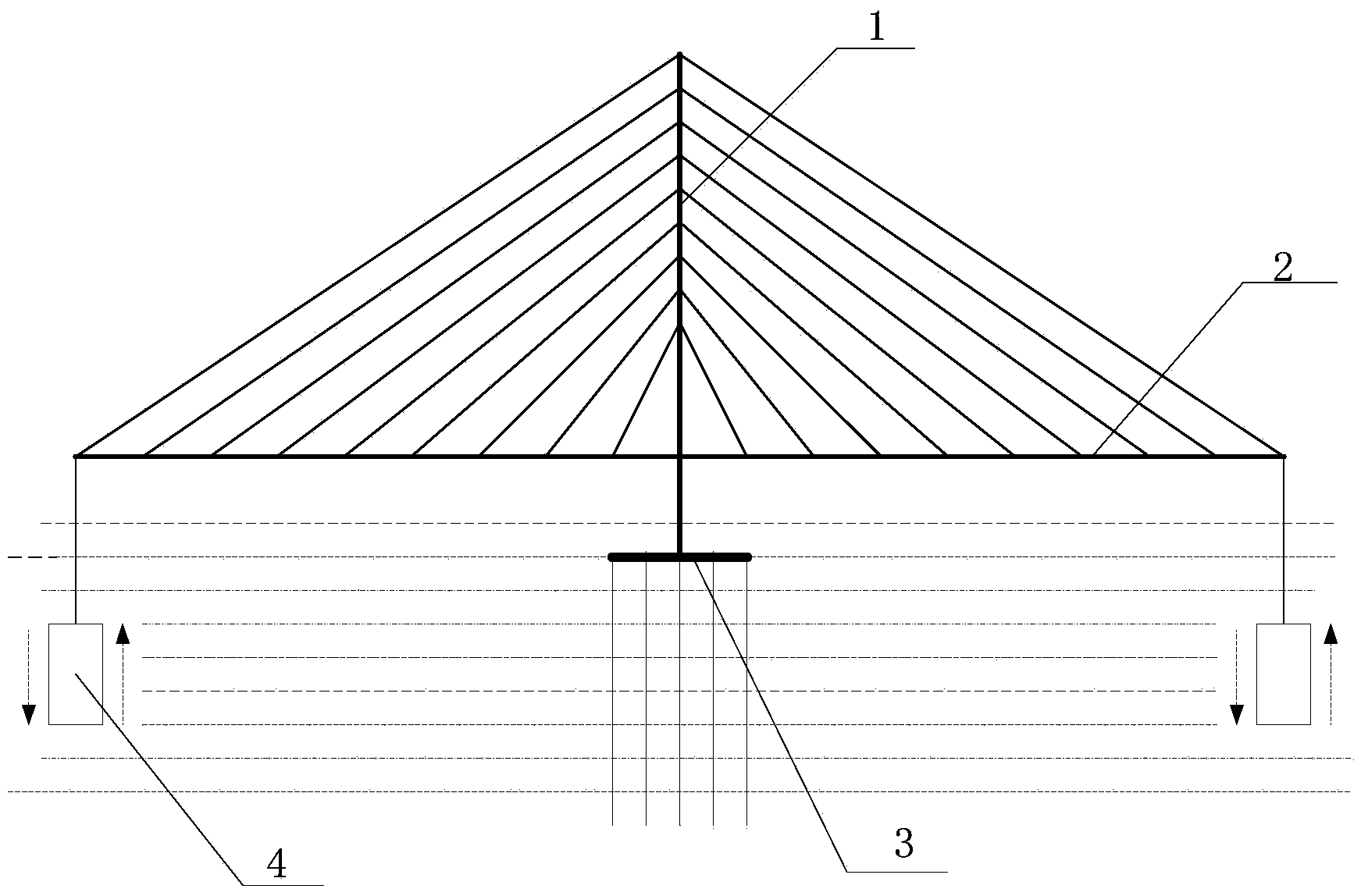

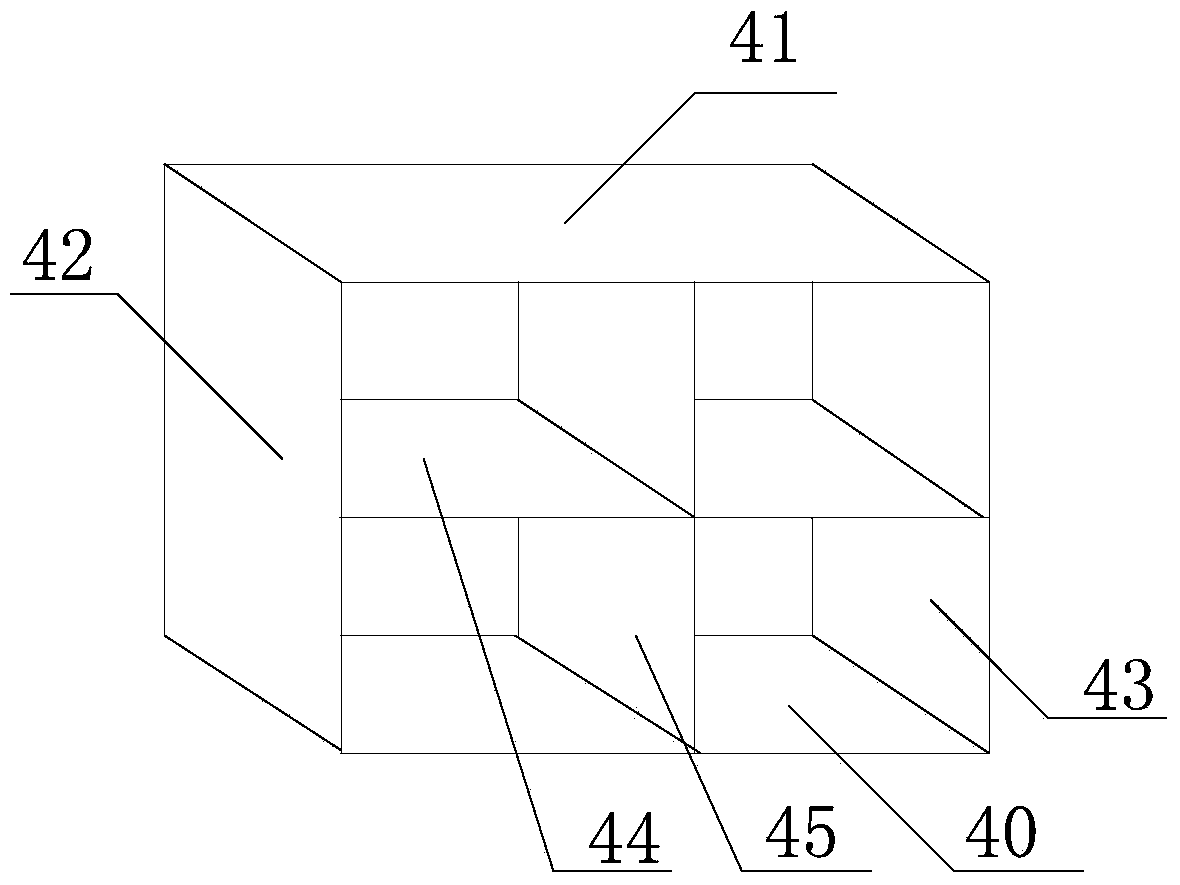

[0038] refer to figure 1 , the cable-stayed bridge system in the construction phase of the present invention comprises a cap 3, a bridge tower 1 and a stiffening beam 2, the bridge tower 1 is vertically fixed on the cap 3, and a number of connection nodes are horizontally arranged on the stiffening beam 2, and the bridge There are several connecting nodes arranged longitudinally on the tower 1, and the connecting nodes on the stiffening beam 2 are connected with the corresponding connecting nodes on the bridge tower 1 through cable-stayed locks. Both ends of the stiffening beam 2 are hung with open underwater vibration dampers 4 , the open-type underwater vibration damper 4 is suspended in the water, and the open-type underwater vibration damper 4 prevents the open-type underwater vibration damper 4 from reciprocating back and forth by making the water generate turbule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com