Polyurethane rigid foam composition, thermal insulation layer and thermal insulation pipe

A technology of polyurethane rigid foam and composition, which is applied in the direction of protecting pipelines through thermal insulation, polyurea/polyurethane coatings, thermal insulation, etc., can solve the problems of easy agglomeration of the composition and uneven unevenness of the thermal insulation layer, so as to avoid the thermal insulation layer of the pipeline. The effect of unevenness, improving the effect of pipe spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

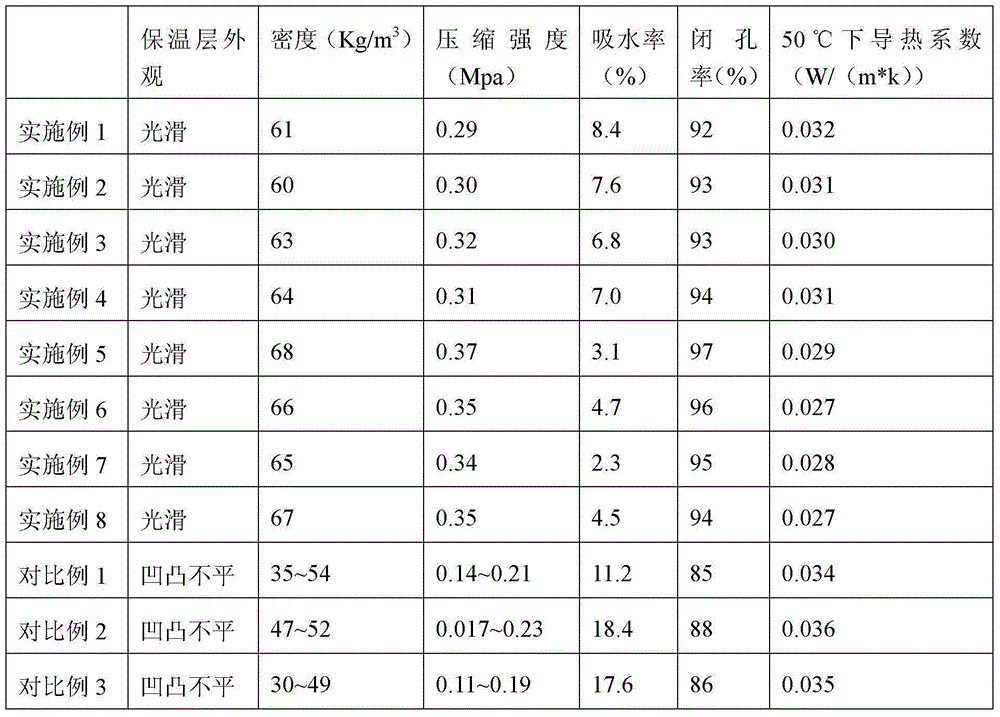

Examples

Embodiment 1

[0037] Configure the polyurethane rigid foam composition, and place it in the sprayer for use, and its components and proportioning are as follows:

[0038] components

[0039] Using the polyurethane rigid foam composition above, prepare an insulation layer on the surface of the pipe by spraying. The specific method is as follows: rotate the pipe to be sprayed (DN300) on a fixed support at a speed of 6r / min. Using a Graco H-VR sprayer, the composition was heated to 70°C. Then, the spray head is set at a distance of 1m from the surface of the pipe to be sprayed, and the spray head is relatively moved in one direction along the axial direction of the pipe at a speed of 1m±0.1m / min to spray the above composition on the outer surface of the pipe . Among them, the surface temperature of the steel pipe is 20°C, and a pipe insulation layer is formed on the surface of the pipe after one-time molding.

Embodiment 2

[0041] Configure the polyurethane rigid foam composition, and place it in the sprayer for use, and its components and proportioning are as follows:

[0042] components

[0043] Utilize above-mentioned rigid polyurethane foam composition, adopt spraying method to prepare insulation layer on pipeline surface, specific method is as shown in embodiment 1.

Embodiment 3

[0045] Configure the polyurethane rigid foam composition, and place it in the sprayer for use, and its components and proportioning are as follows:

[0046] components

[0047] Potassium acetate

[0048] Utilize above-mentioned rigid polyurethane foam composition, adopt spraying method to prepare insulation layer on pipeline surface, specific method is as shown in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com