IM-5 molecular sieve synthesis method

An IM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of low utilization rate of active centers, large diffusion resistance of large particle size molecular sieves, easy deactivation, etc., to shorten the crystallization time and reduce impurities. The formation of crystal phase, the effect of promoting depolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

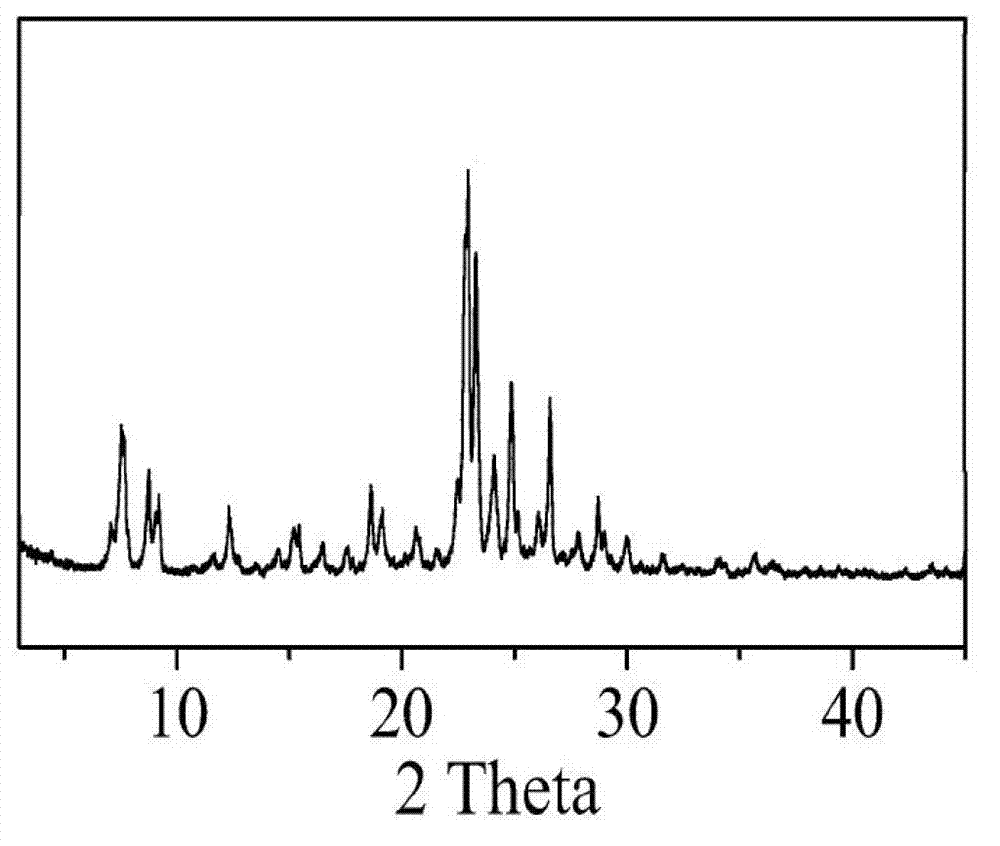

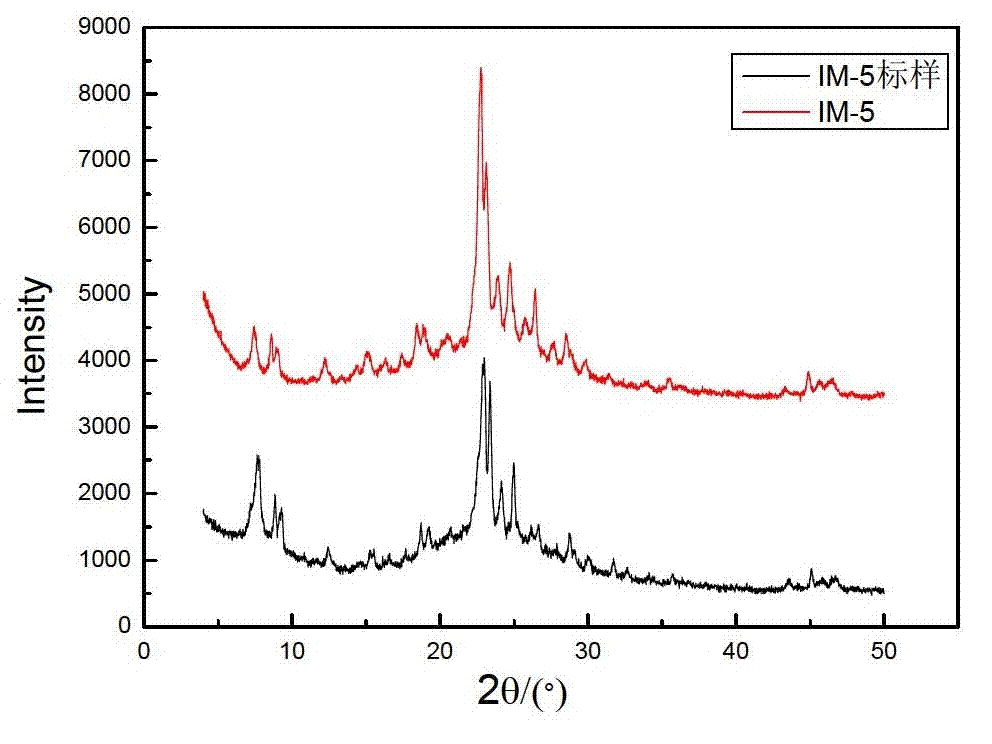

[0066] According to the method of comparative example 3, sodium metaaluminate (NaAlO 2 ) solution, 2.00g NaAlO 2solution, 1.27g NaOH, 0.26g MP solution and 2.74g MPPBr solution were dissolved in an appropriate amount of deionized water, mixed evenly, under the condition of stirring, 6.51g of solid coarse-pore silica gel particles were added, and stirred evenly. The molar composition of the reaction mixture is SiO 2 :Al 2 o 3 : Na 2 O: R: A: H 2 O=60:1:11.4:6:1.8:600. Transfer the prepared colloid to a 50ml polytetrafluoroethylene-lined autoclave, rotate and crystallize at 160°C for 6 days, stop the crystallization reaction, wash and filter the product, and dry it at 80°C to obtain IM -5 molecular sieves. The XRD diffraction pattern of the obtained sample is shown in the attached image 3 As shown, the scanning electron microscope spectrum is shown as Figure 6 shown.

Embodiment 2

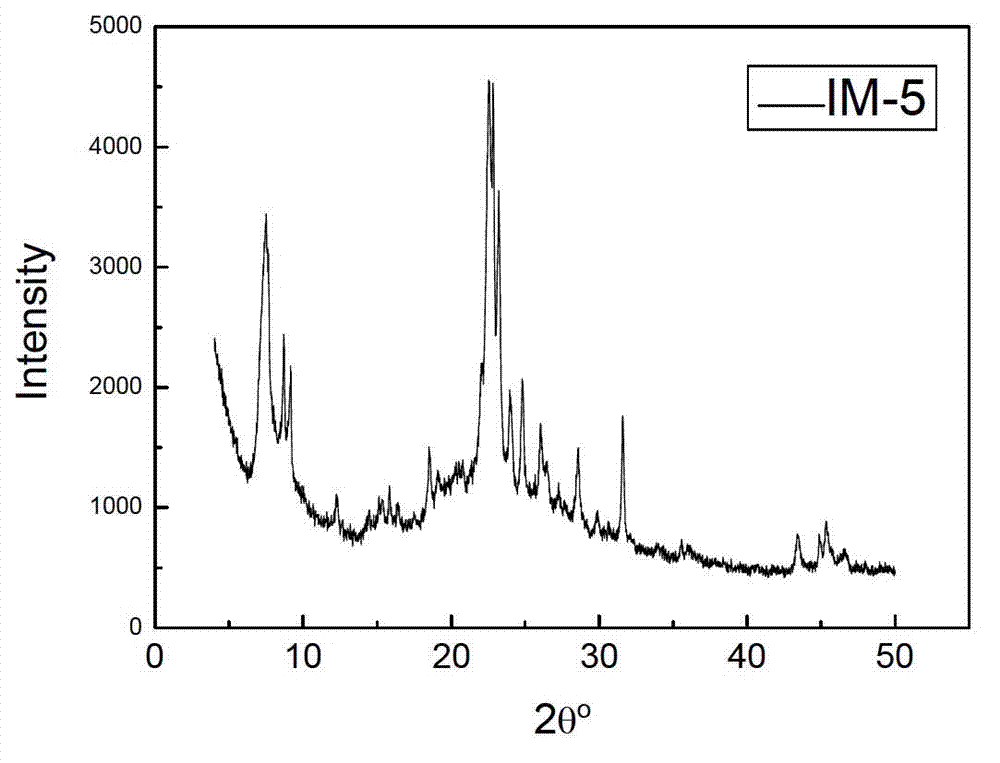

[0068] According to the method of comparative example 3, sodium metaaluminate (NaAlO 2 ) solution, 2.00g NaAlO 2 solution, 0.75g NaOH, 3.04g MPPOH solution and 6.84g MPPBr solution were dissolved in an appropriate amount of deionized water, mixed evenly, and under stirring conditions, 6.51g of solid coarse-pore silica gel particles were added, and stirred evenly. The molar composition of the reaction mixture is SiO 2 :Al 2 o 3 : Na 2 O: R: A: H 2 O=60:1:7.5:4.5:3:600. Transfer the obtained colloid to a 50ml polytetrafluoroethylene-lined autoclave, crystallize at 140°C for 1 day, crystallize at 160°C for 5 days, stop the crystallization reaction, and wash and filter the product, then store it at 80°C After drying, IM-5 molecular sieve can be obtained. The XRD diffraction pattern of the obtained sample is shown in the attached Figure 4 shown.

Embodiment 3

[0070] 1.67g Al(NO 3 ) 3 9H 2 0. Dissolve 1.60g NaOH, 13.70g MPPBr solution and 0.26g MP solution in an appropriate amount of deionized water, mix well, and add 6.51g of solid coarse-pore silica gel particles under stirring conditions, and stir well. The molar composition of the reaction mixture is: SiO 2 :Al 2 o 3 : Na 2 O: R: A: H 2 O=60:2:12:9:1.8:600. The prepared colloid was transferred to a 50ml polytetrafluoroethylene-lined autoclave, crystallized at 160°C for 1 day, crystallized at 175°C for 5 days, stopped the crystallization reaction, and the product was washed and filtered for 80 ℃ drying overnight to obtain IM-5 molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com